Motor protection and control

Manual motor starters,

A9 ... A300 contactors

and overload relays

Main catalog

Motor protection and control

Manual motor starters,

A9 ... A300 contactors

and overload relays

Main catalog

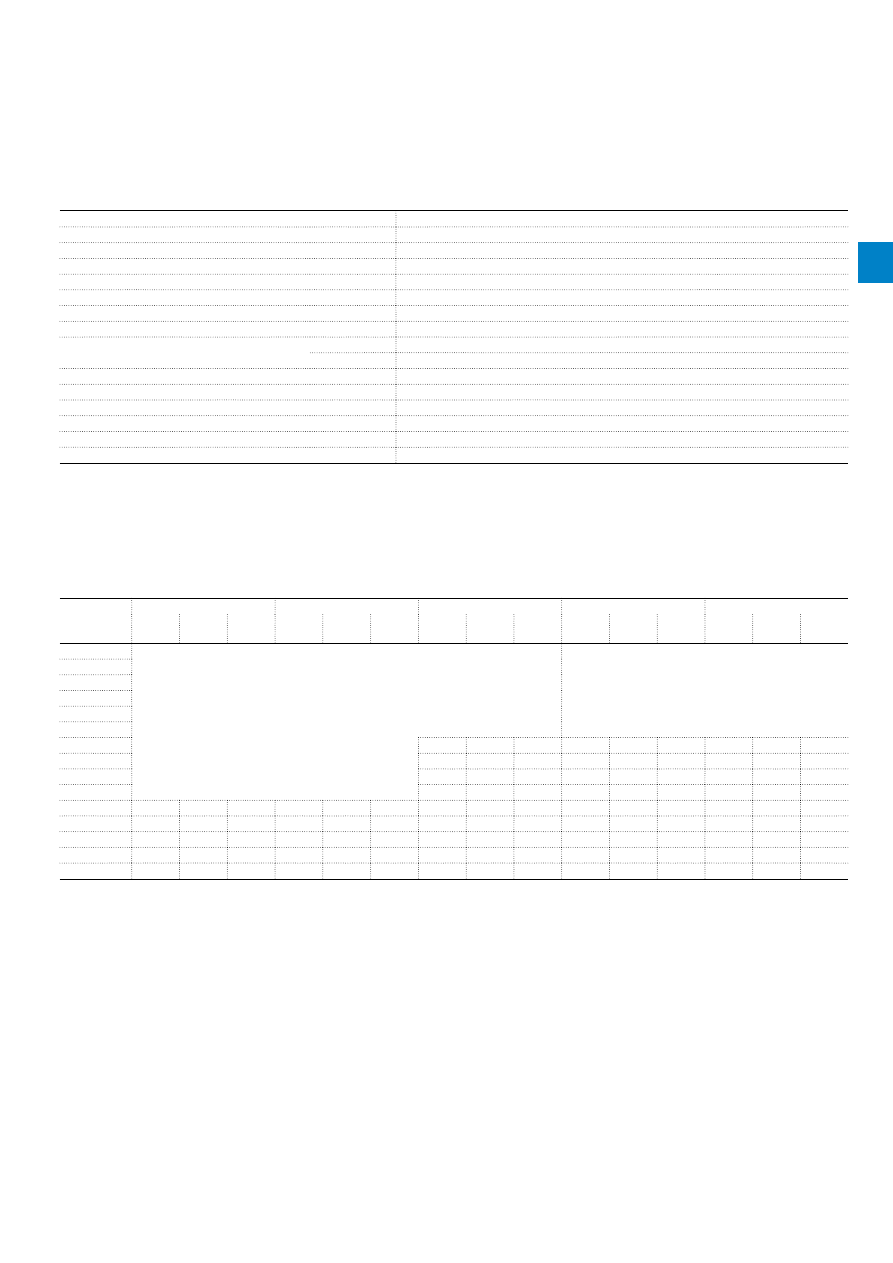

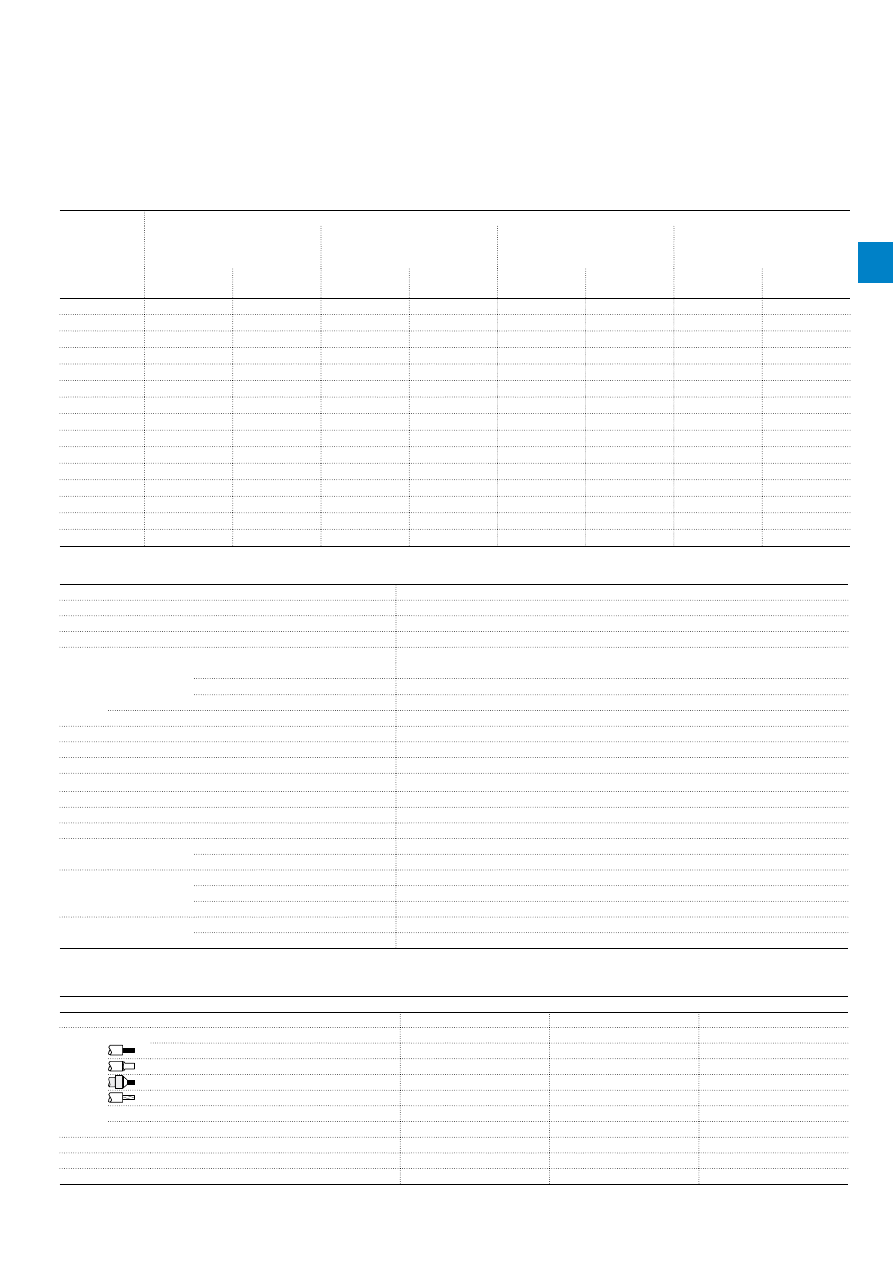

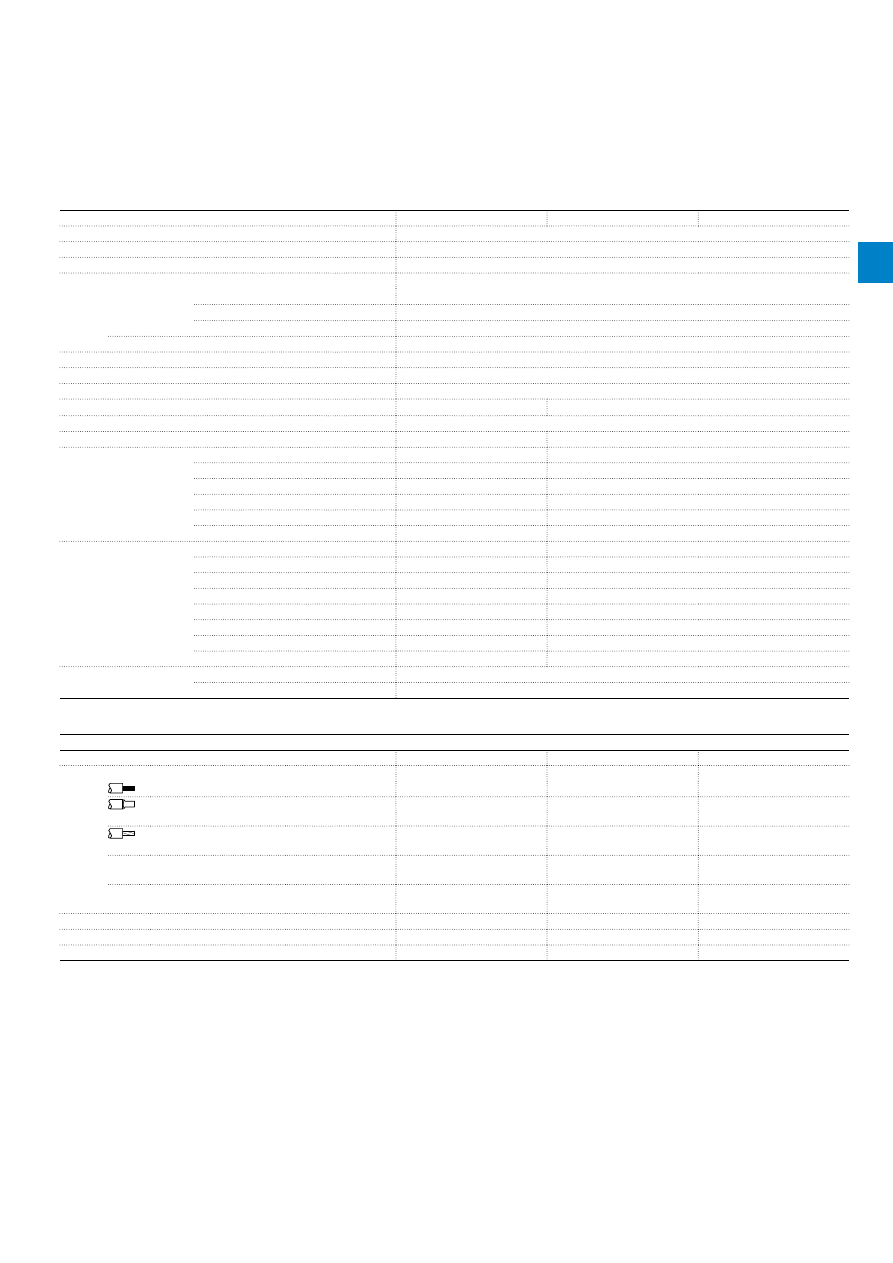

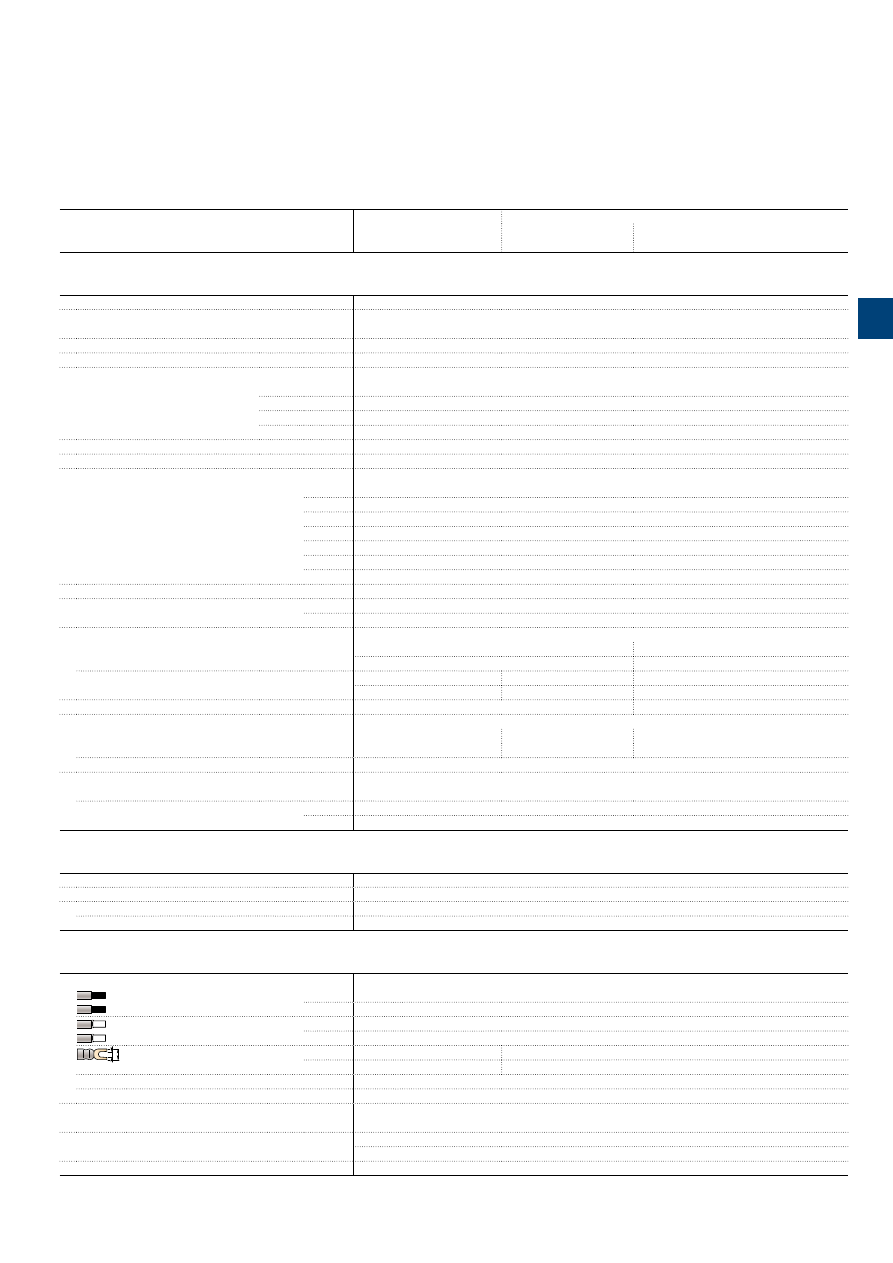

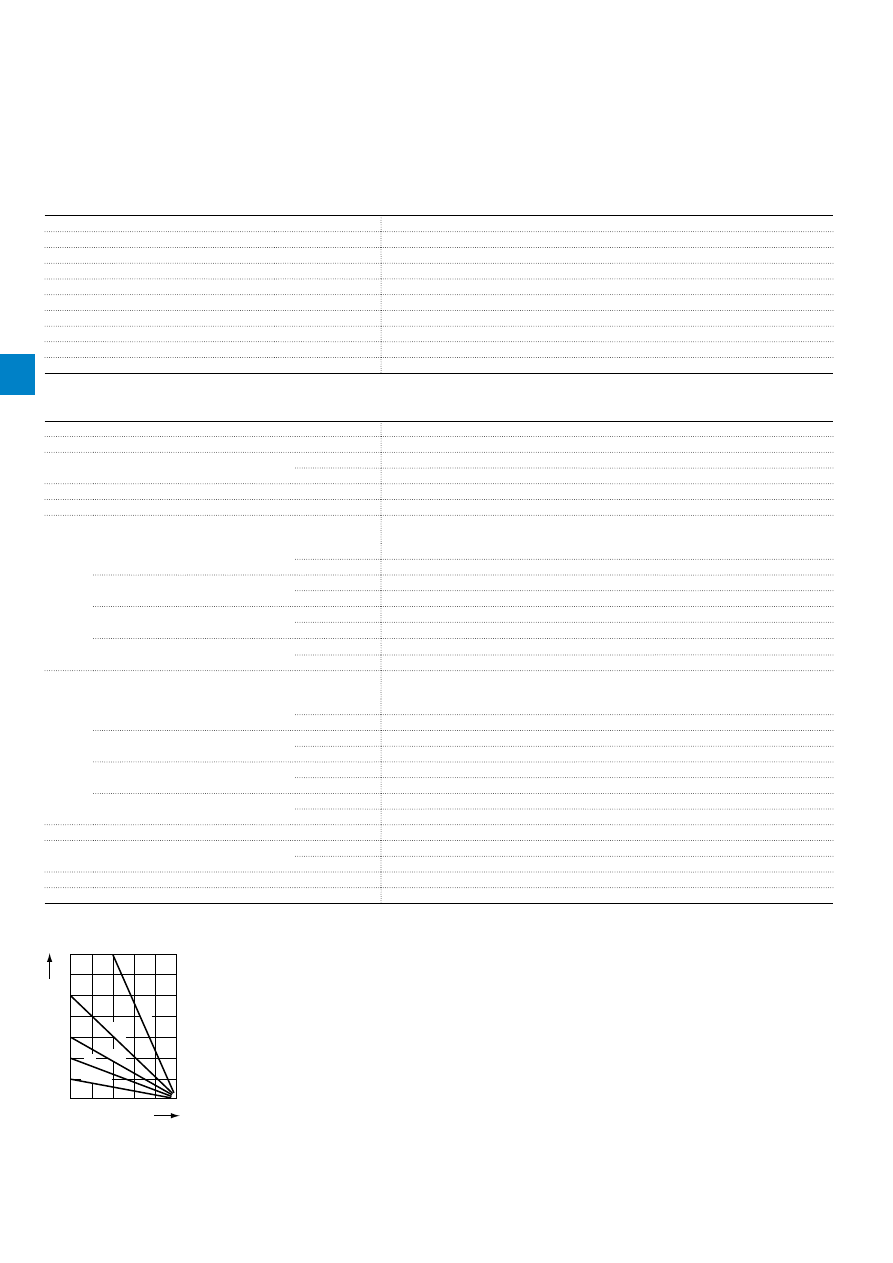

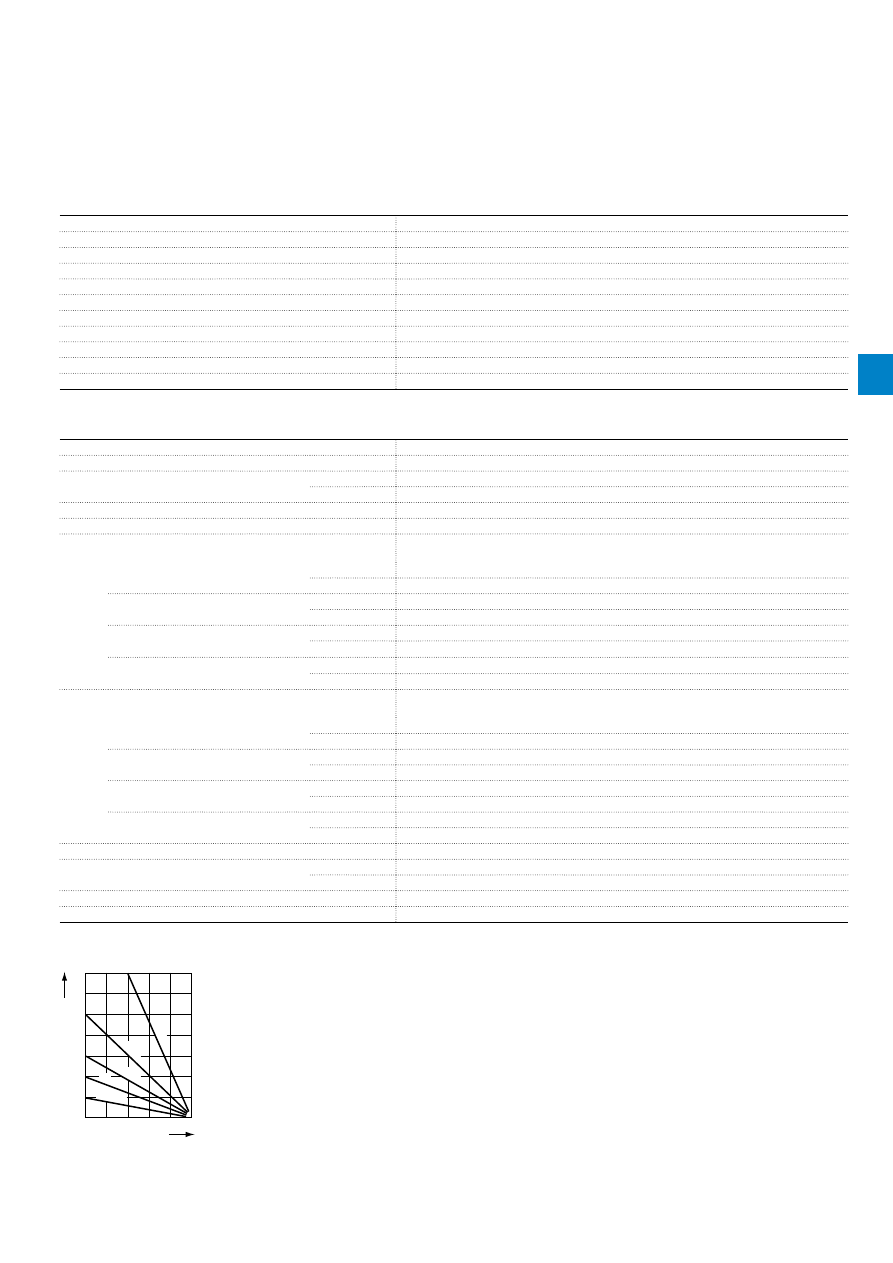

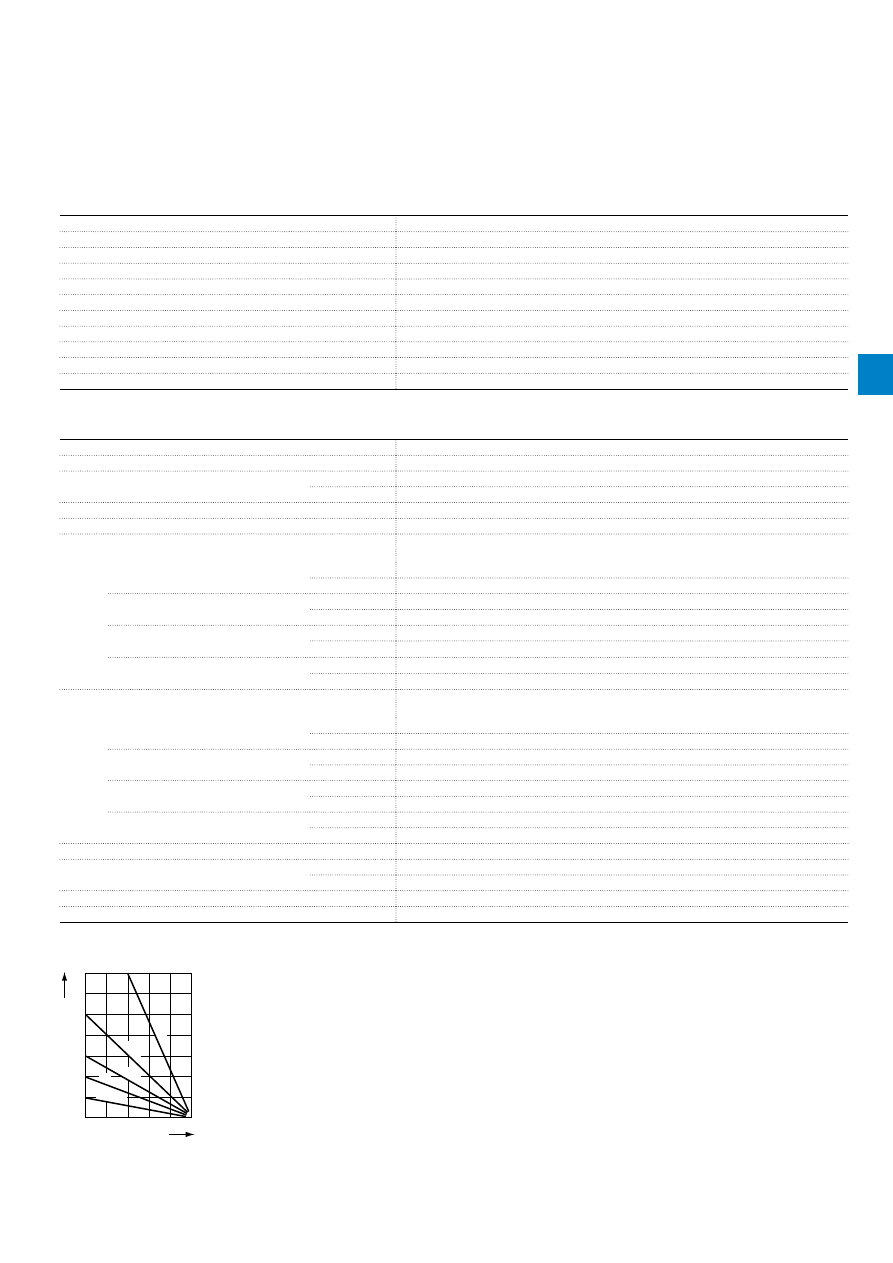

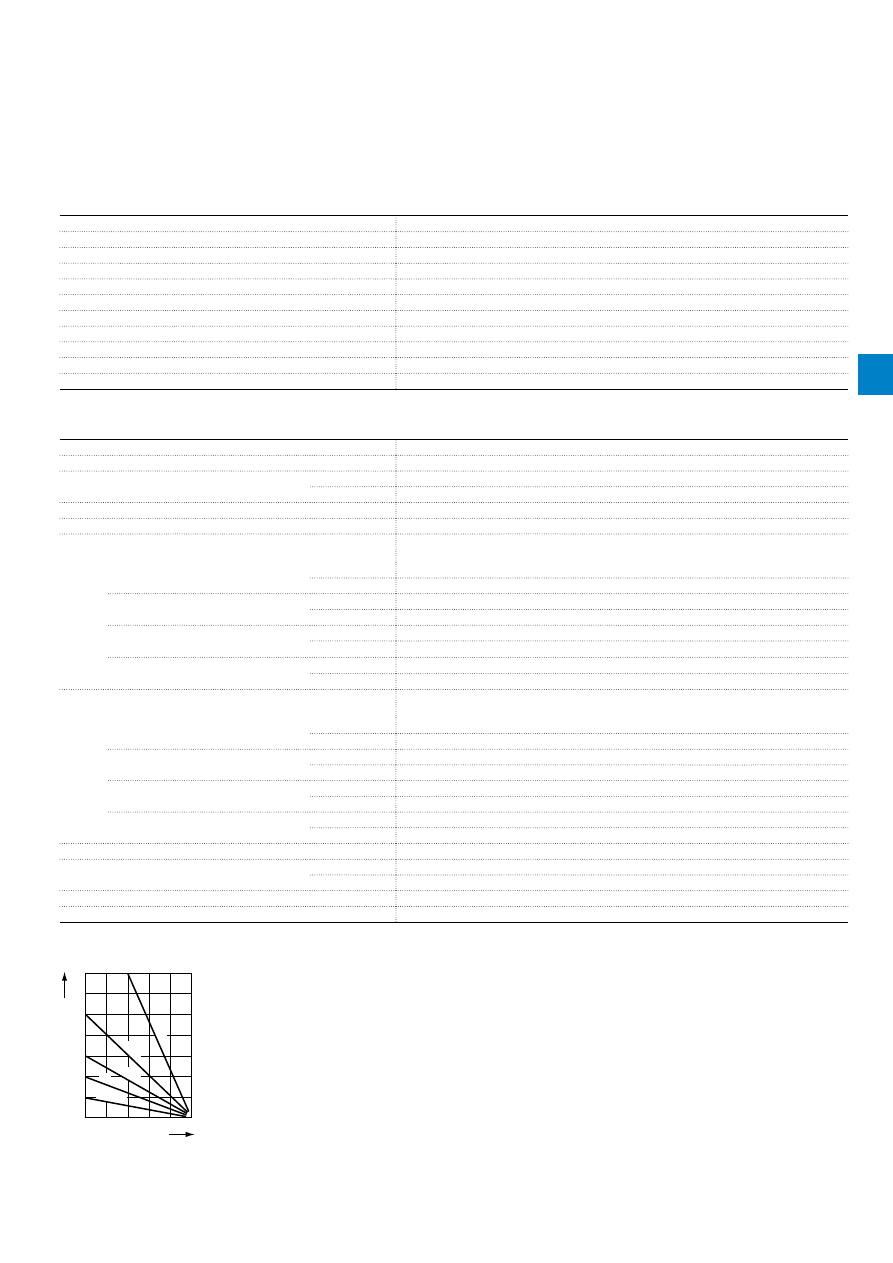

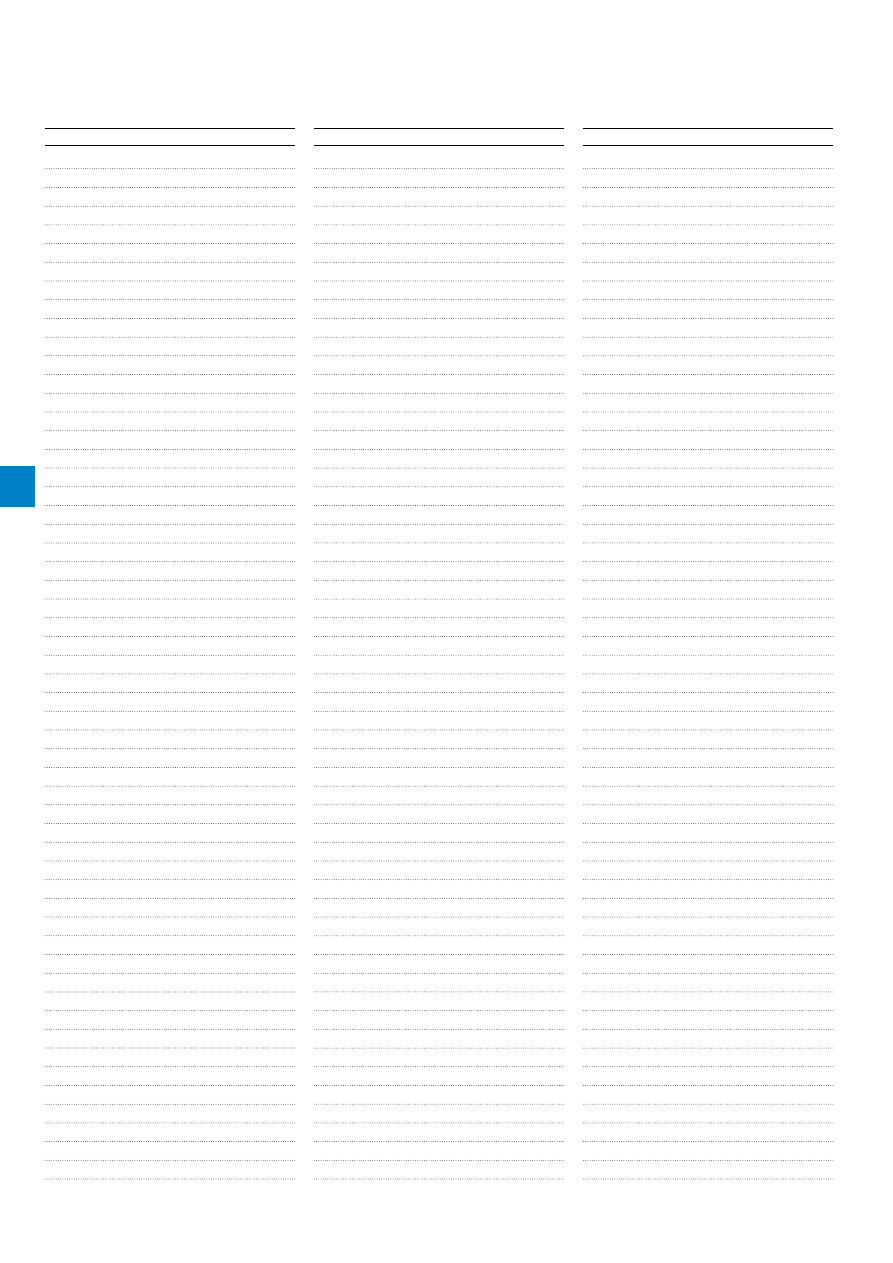

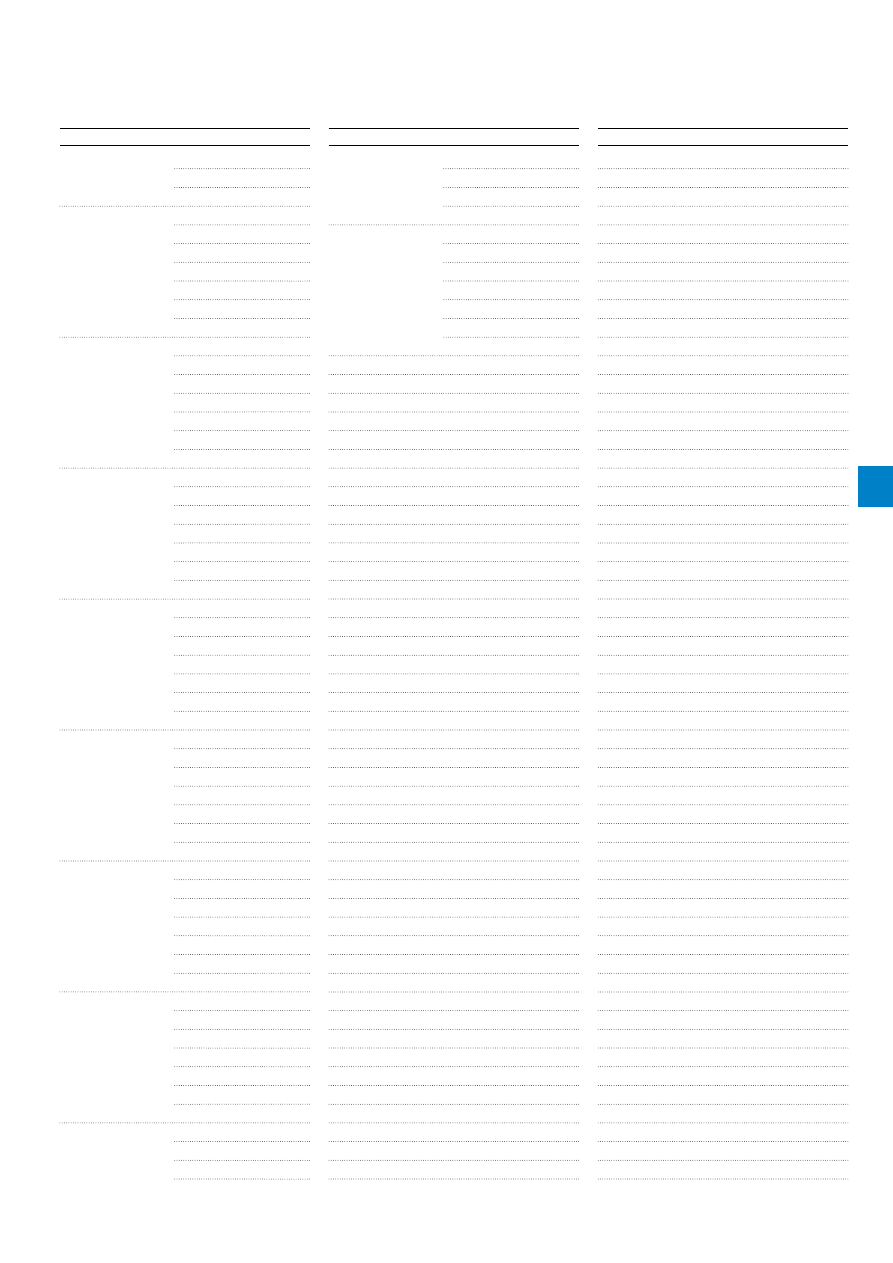

Motor rated operational powers and currents

The currents given below concern standard three-phase four-pole cage motors (1500 r.p.m. at 50 Hz 1800 r.p.m. at 60 Hz).

These values are given for guidance and may vary according to the motor manufacturer and depending on the number of poles.

IEC

Motor nominal current:

standardized values in blue colour

(according to IEC 60947-4-1 Annex G)

Motor

power

220 V

230 V

240 V 380 V

400 V

415 V 440 V

500 V

660 V

690 V

kW

A

A

A

A

A

A

A

A

A

A

0.06

0.37

0.35

0.34

0.21

0.2

0.19

0.18

0.16

0.13

0.12

0.09

0.54

0.52

0.50

0.32

0.3

0.29

0.26

0.24

0.18

0.17

0.12

0.73

0.7

0.67

0.46

0.44

0.42

0.39

0.32

0.24

0.23

0.18

1

1

1

0.63

0.6

0.58

0.53

0.48

0.37

0.35

0.25

1.6

1.5

1.4

0.9

0.85

0.82

0.74

0.68

0.51

0.49

0.37

2.0

1.9

1.8

1.2

1.1

1.1

1

0.88

0.67

0.64

0.55

2.7

2.6

2.5

1.6

1.5

1.4

1.3

1.2

0.91

0.87

0.75

3.5

3.3

3.2

2.0

1.9

1.8

1.7

1.5

1.15

1.1

1.1

4.9

4.7

4.5

2.8

2.7

2.6

2.4

2.2

1.7

1.6

1.5

6.6

6.3

6

3.8

3.6

3.5

3.2

2.9

2.2

2.1

2.2

8.9

8.5

8.1

5.2

4.9

4.7

4.3

3.9

2.9

2.8

3

11.8

11.3

10.8

6.8

6.5

6.3

5.7

5.2

4

3.8

4

15.7

15

14.4

8.9

8.5

8.2

7.4

6.8

5.1

4.9

5.5

20.9

20

19.2

12.1

11.5

11.1

10.1

9.2

7

6.7

7.5

28.2

27

25.9

16.3

15.5

14.9

13.6

12.4

9.3

8.9

11

39.7

38

36.4

23.2

22

21.2

19.3

17.6

13.4

12.8

15

53.3

51

48.9

30.5

29

28

25.4

23

17.8

17

18.5

63.8

61

58.5

36.8

35

33.7

30.7

28

22

21

22

75.3

72

69

43.2

41

39.5

35.9

33

25.1

24

30

100

96

92

57.9

55

53

48.2

44

33.5

32

37

120

115

110

69

66

64

58

53

40.8

39

45

146

140

134

84

80

77

70

64

49.1

47

55

177

169

162

102

97

93

85

78

59.6

57

75

240

230

220

139

132

127

116

106

81

77

90

291

278

266

168

160

154

140

128

97

93

110

355

340

326

205

195

188

171

156

118

113

132

418

400

383

242

230

222

202

184

140

134

160

509

487

467

295

280

270

245

224

169

162

200

637

609

584

368

350

337

307

280

212

203

250

782

748

717

453

430

414

377

344

261

250

315

983

940

901

568

540

520

473

432

327

313

355

1109

1061

1017 642

610

588

535

488

370

354

400

1255

1200

1150 726

690

665

605

552

418

400

500

1545

1478

1416 895

850

819

745

680

515

493

560

1727

1652

1583 1000

950

916

832

760

576

551

630

1928

1844

1767 1116

1060

1022 929

848

643

615

710

2164

2070

1984 1253

1190

1147 1043

952

721

690

800

2446

2340

2243 1417

1346

1297 1179

1076

815

780

900

2760

2640

2530 1598

1518

1463 1330

1214

920

880

1000

3042

2910

2789 1761

1673

1613 1466

1339

1014

970

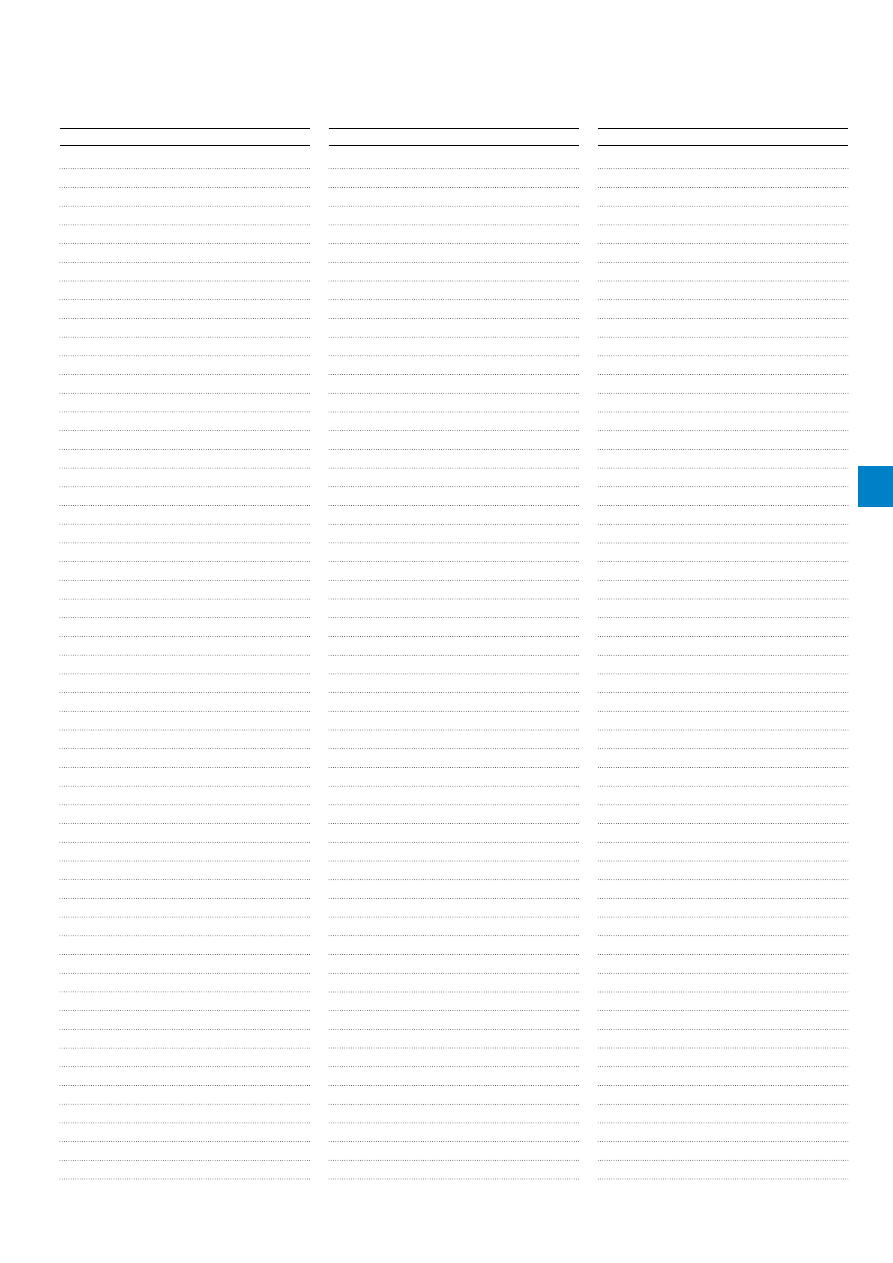

UL / CSA

Motor nominal current:

standardized values

(according to IEC 60947-4-1 Annex G and UL 508)

Motor

power

208 V

220-240 V

380-415 V

440-480 V

550-600 V

hp

A

A

A

A

A

1/2

2.4

2.2

1.3

1.1

0.9

3/4

3.5

3.2

1.8

1.6

1.3

1

4.6

4.2

2.3

2.1

1.7

1-1/2

6.6

6

3.3

3

2.4

2

7.5

6.8

4.3

3.4

2.7

3

10.6

9.6

6.1

4.8

3.9

5

16.7

15.2

9.7

7.6

6.1

7-1/2

24.2

22

14

11

9

10

30.8

28

18

14

11

15

46.2

42

27

21

17

20

59.4

54

34

27

22

25

74.8

68

44

34

27

30

88

80

51

40

32

40

114

104

66

52

41

50

143

130

83

65

52

60

169

154

103

77

62

75

211

192

128

96

77

100

273

248

165

124

99

125

343

312

208

156

125

150

396

360

240

180

144

200

528

480

320

240

192

250

–

604

403

302

242

300

–

722

482

361

289

350

–

828

560

414

336

400

–

954

636

477

382

450

–

1030

–

515

412

500

–

1180

786

590

472

1S

B

C

10

15

8

9

S

0

2

01

S

umma

ry

_1

ABB

|

1

/1

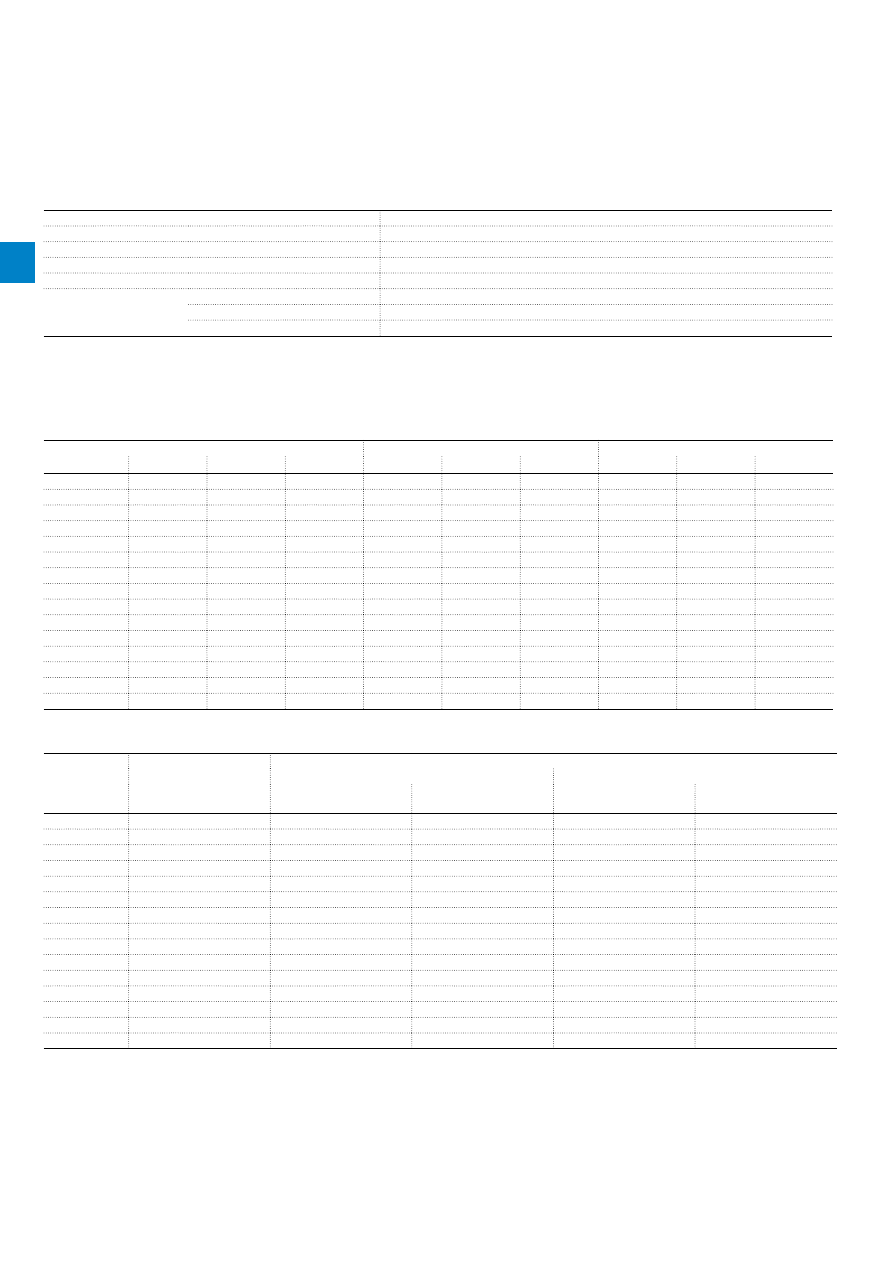

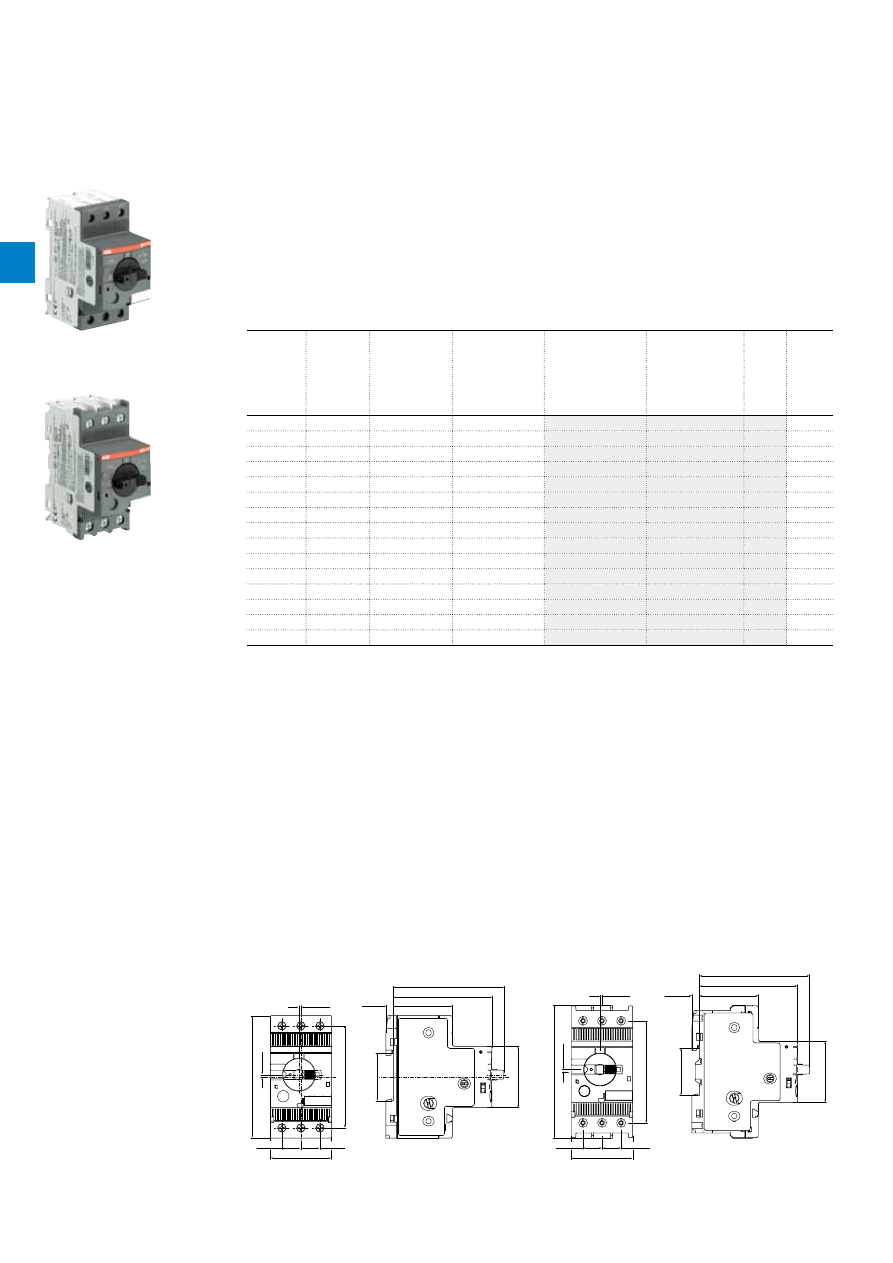

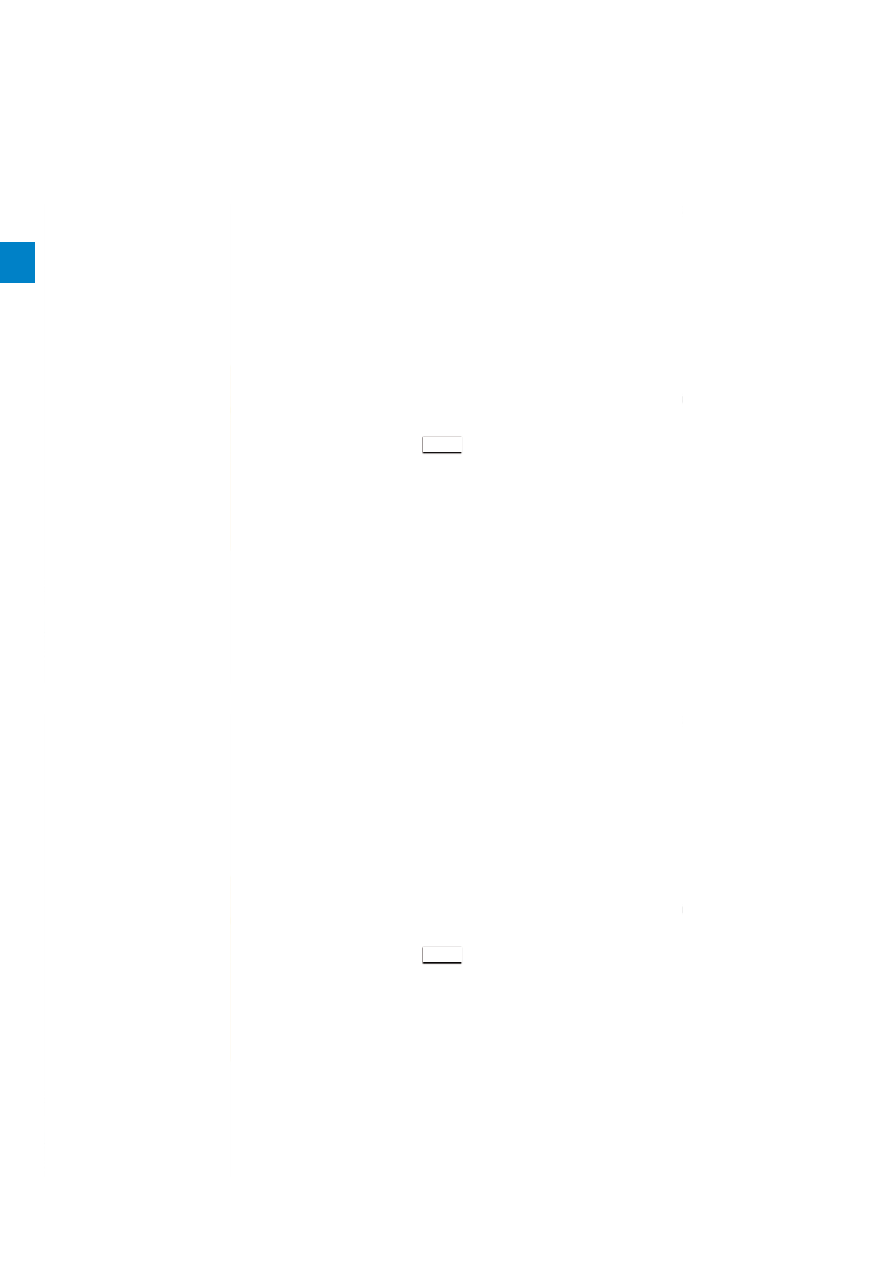

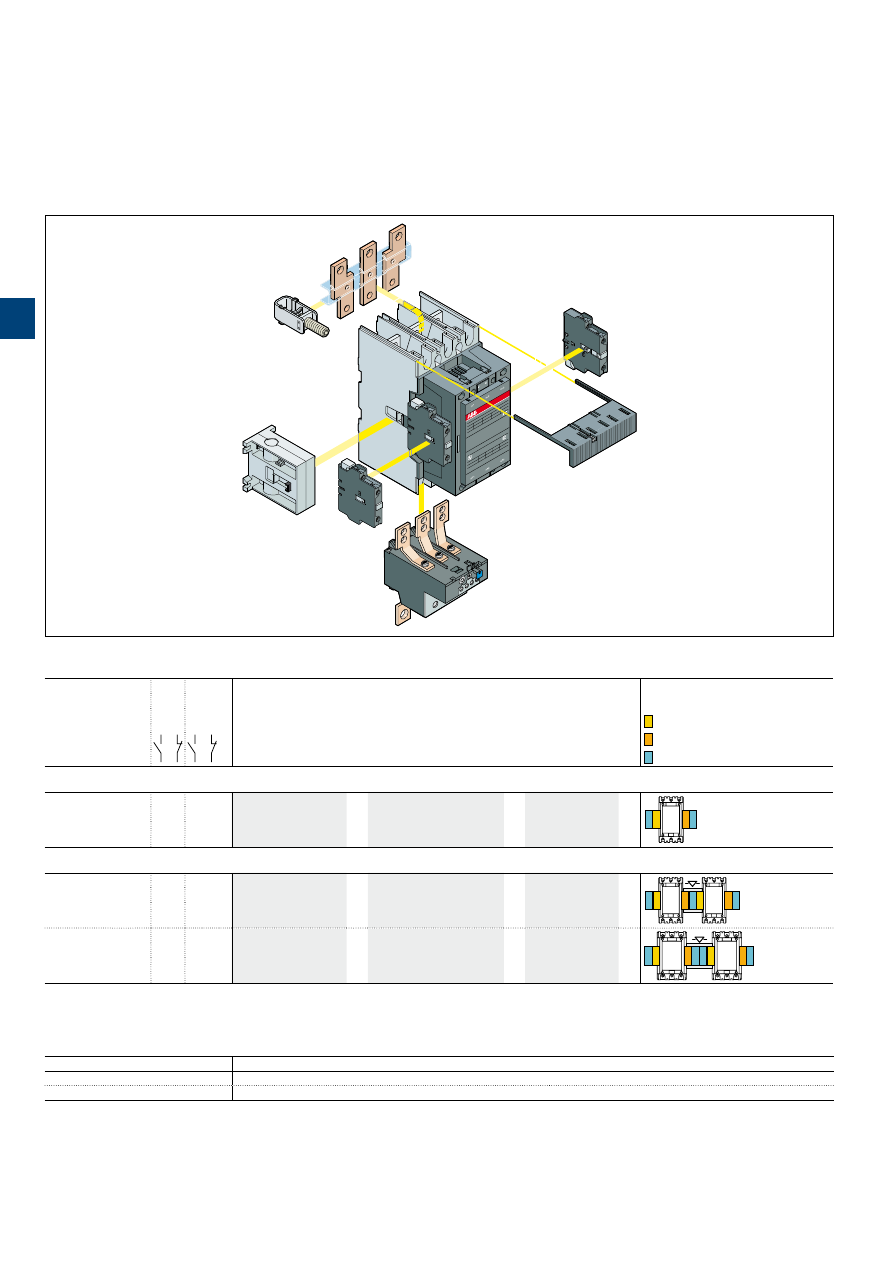

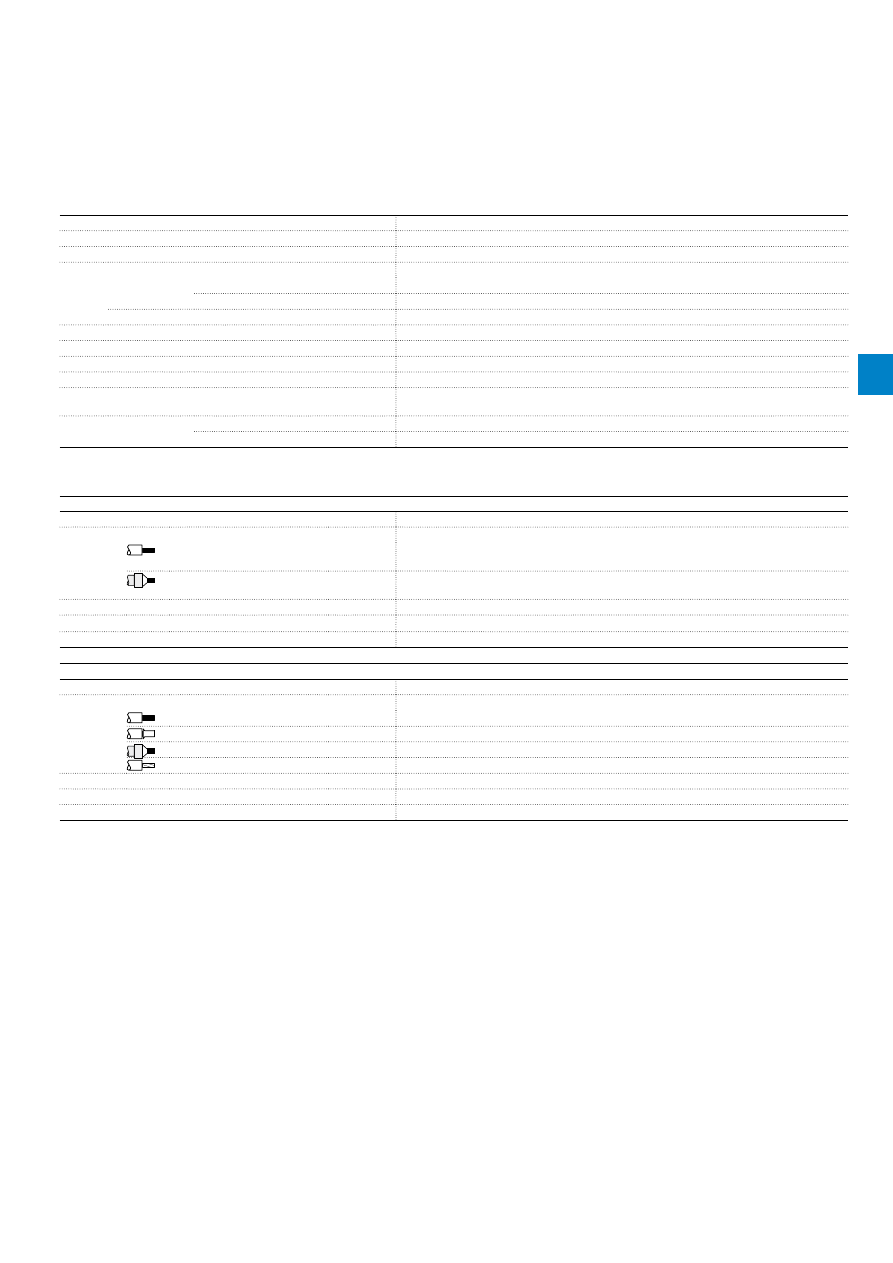

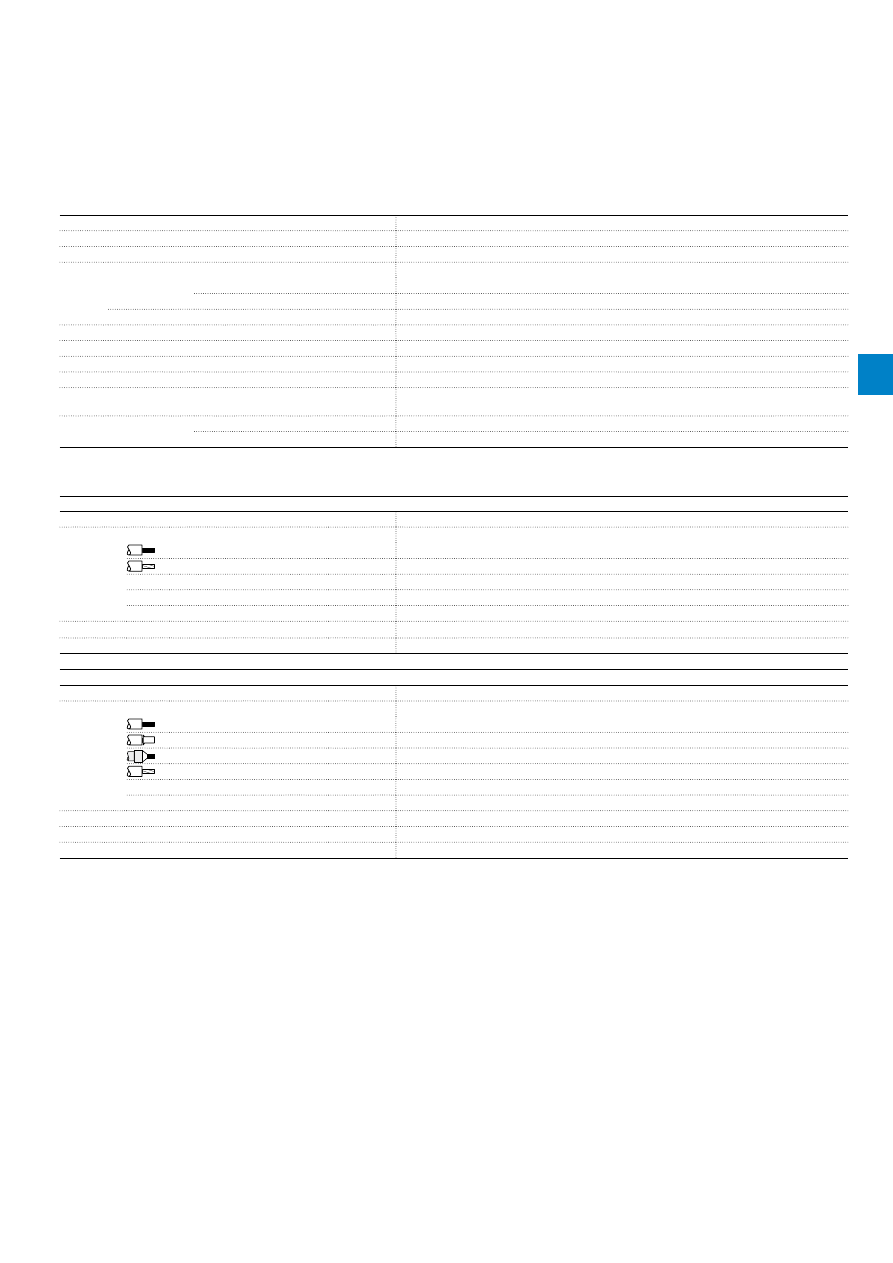

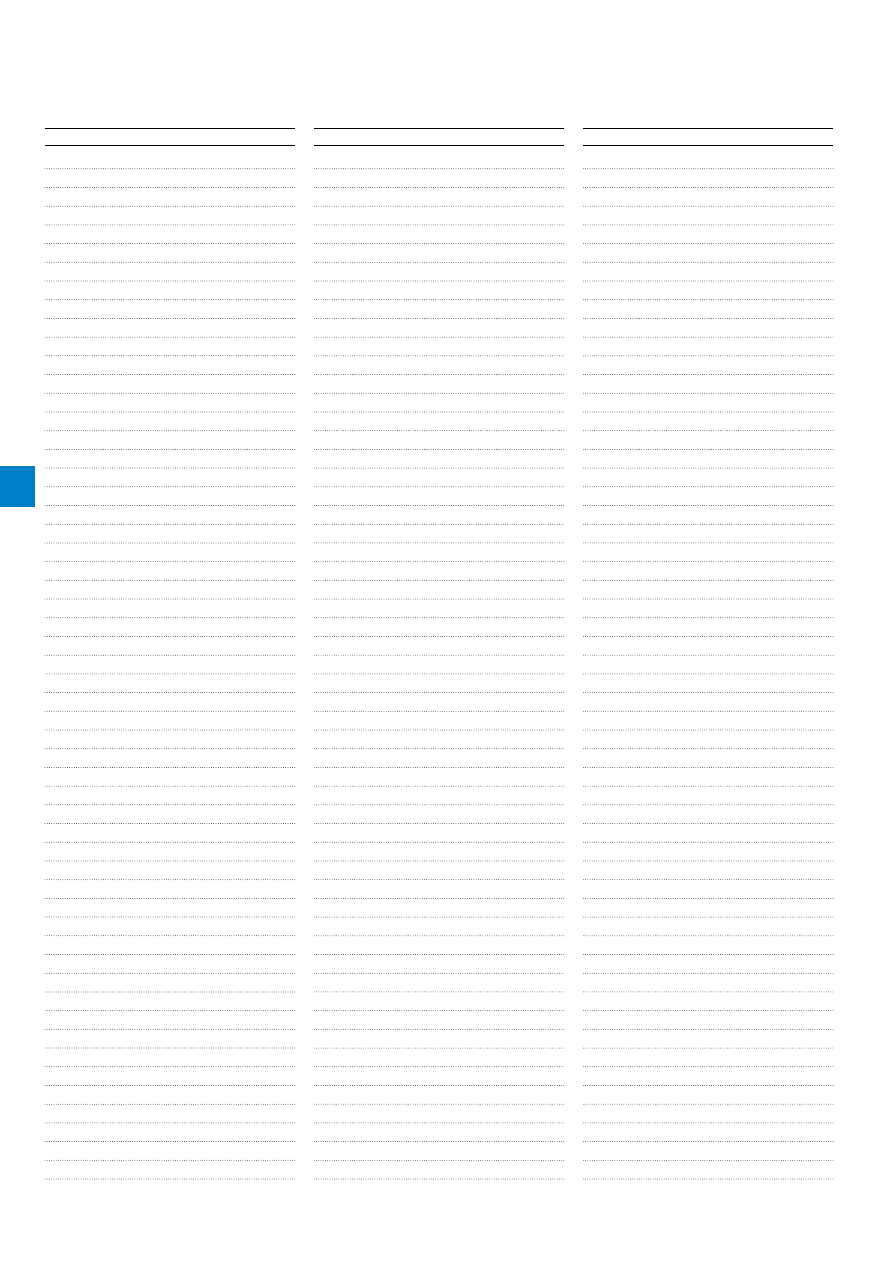

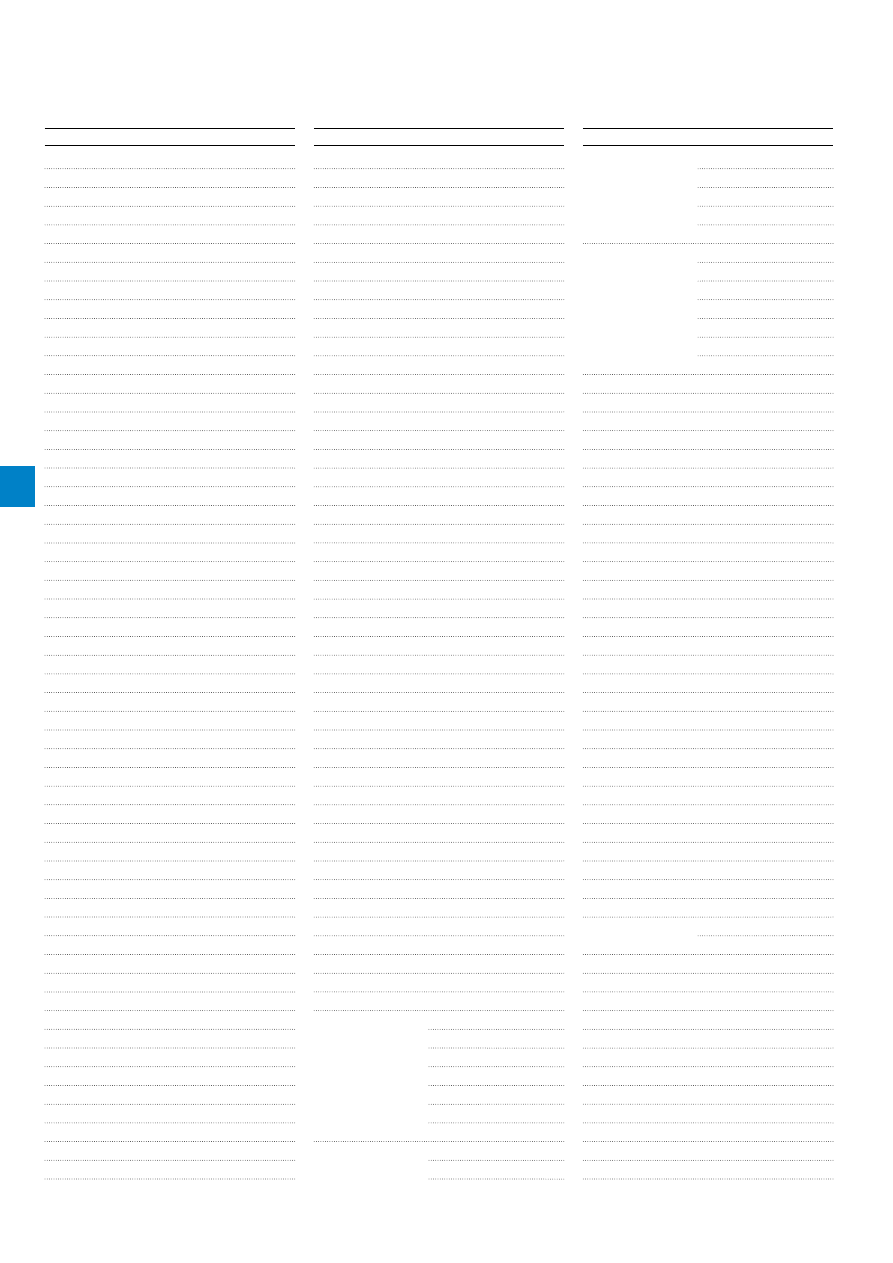

Motor protection and control

Manual motor starters, contactors and overload relays

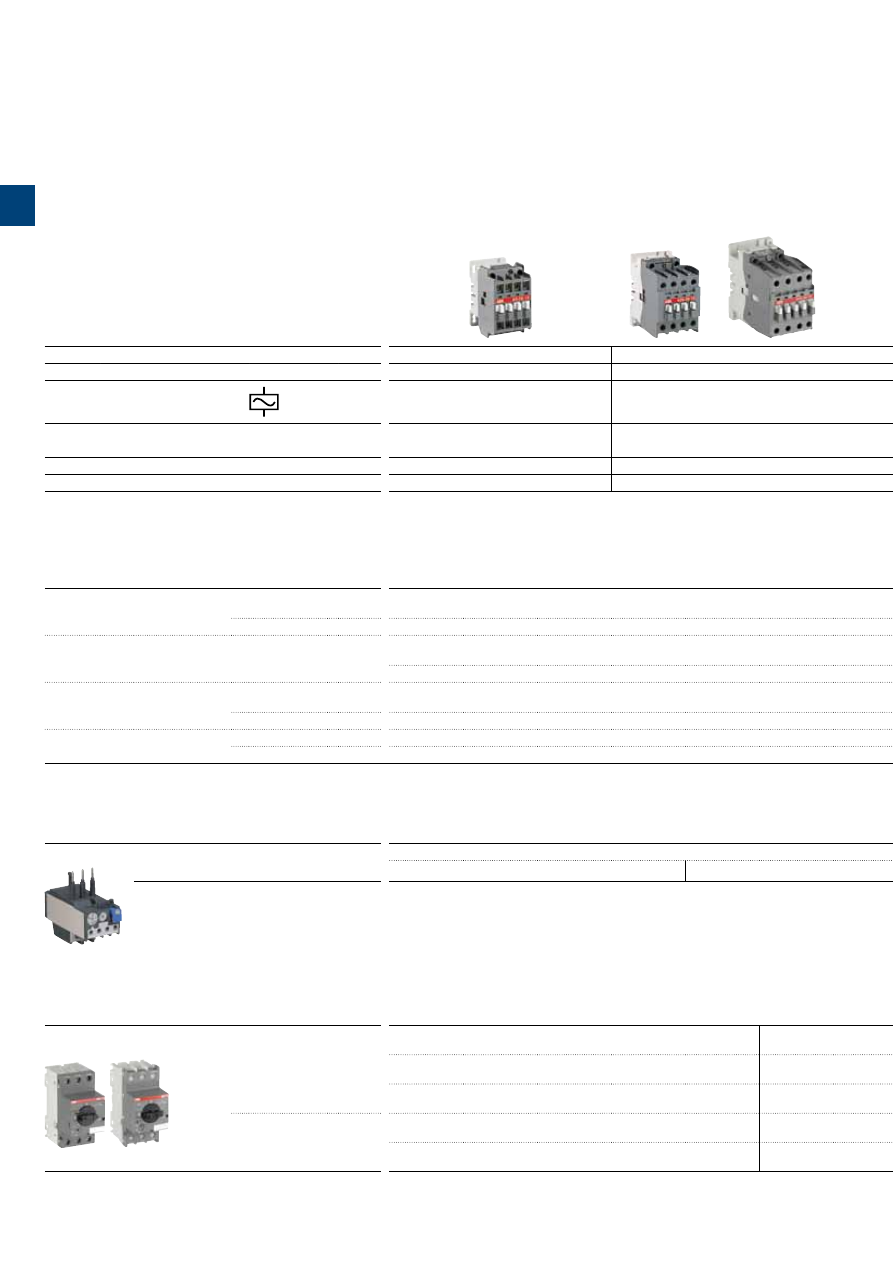

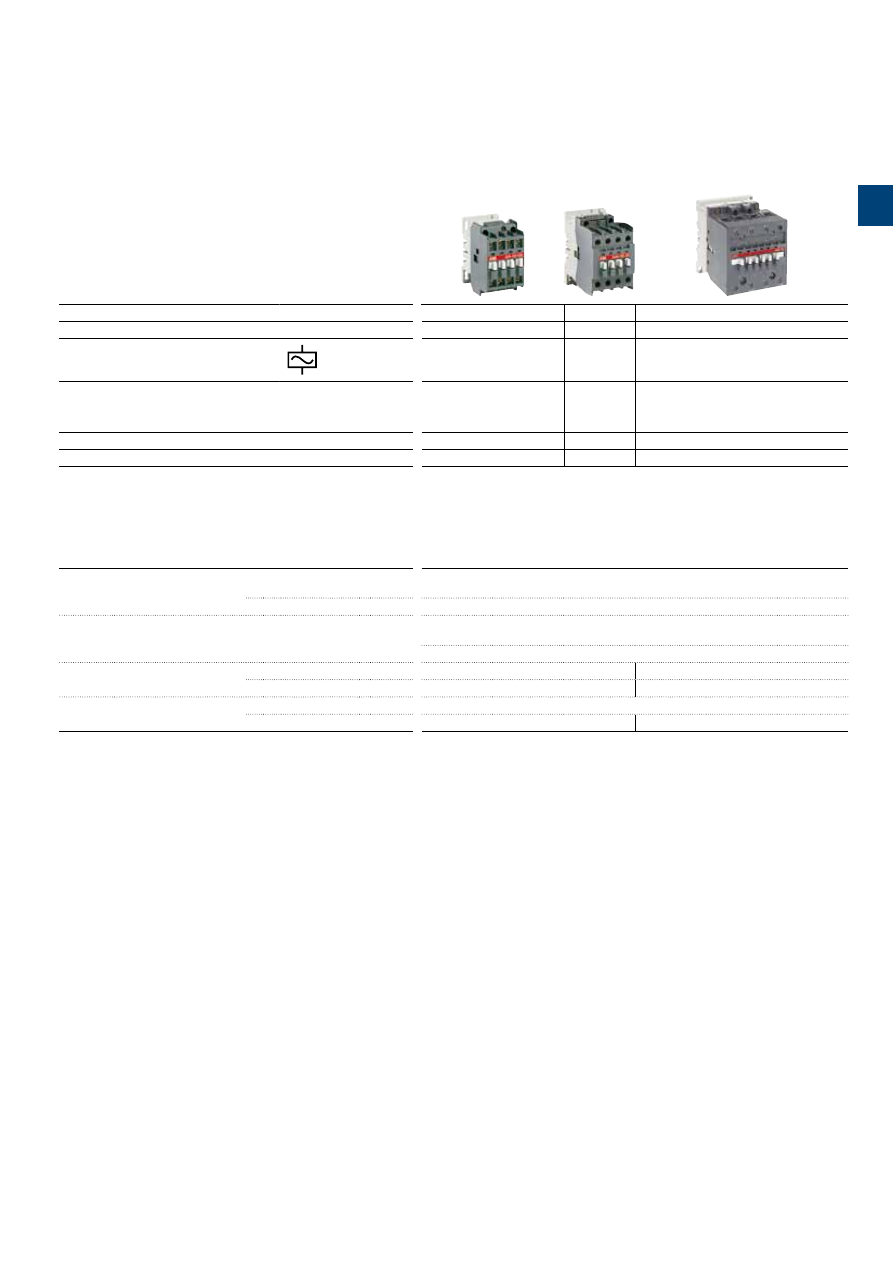

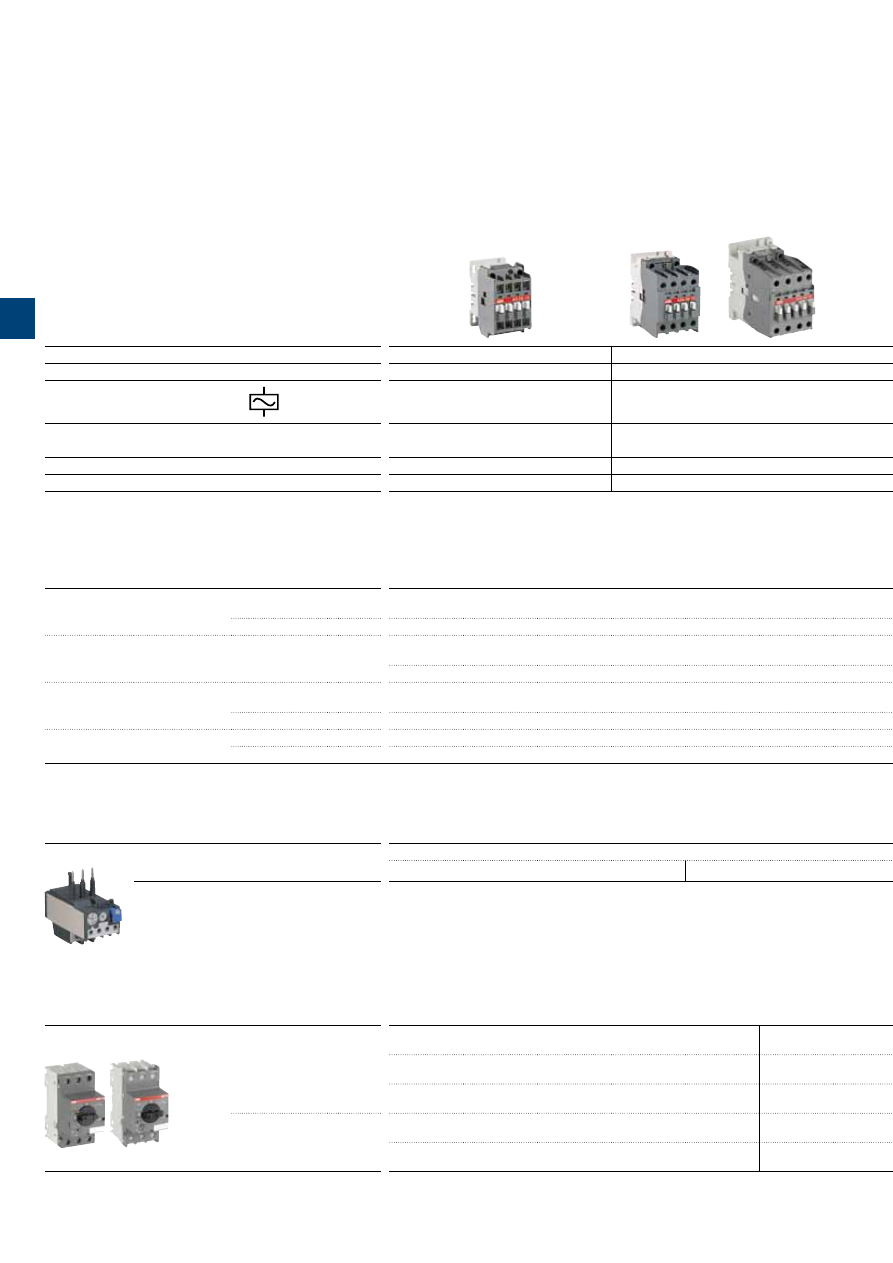

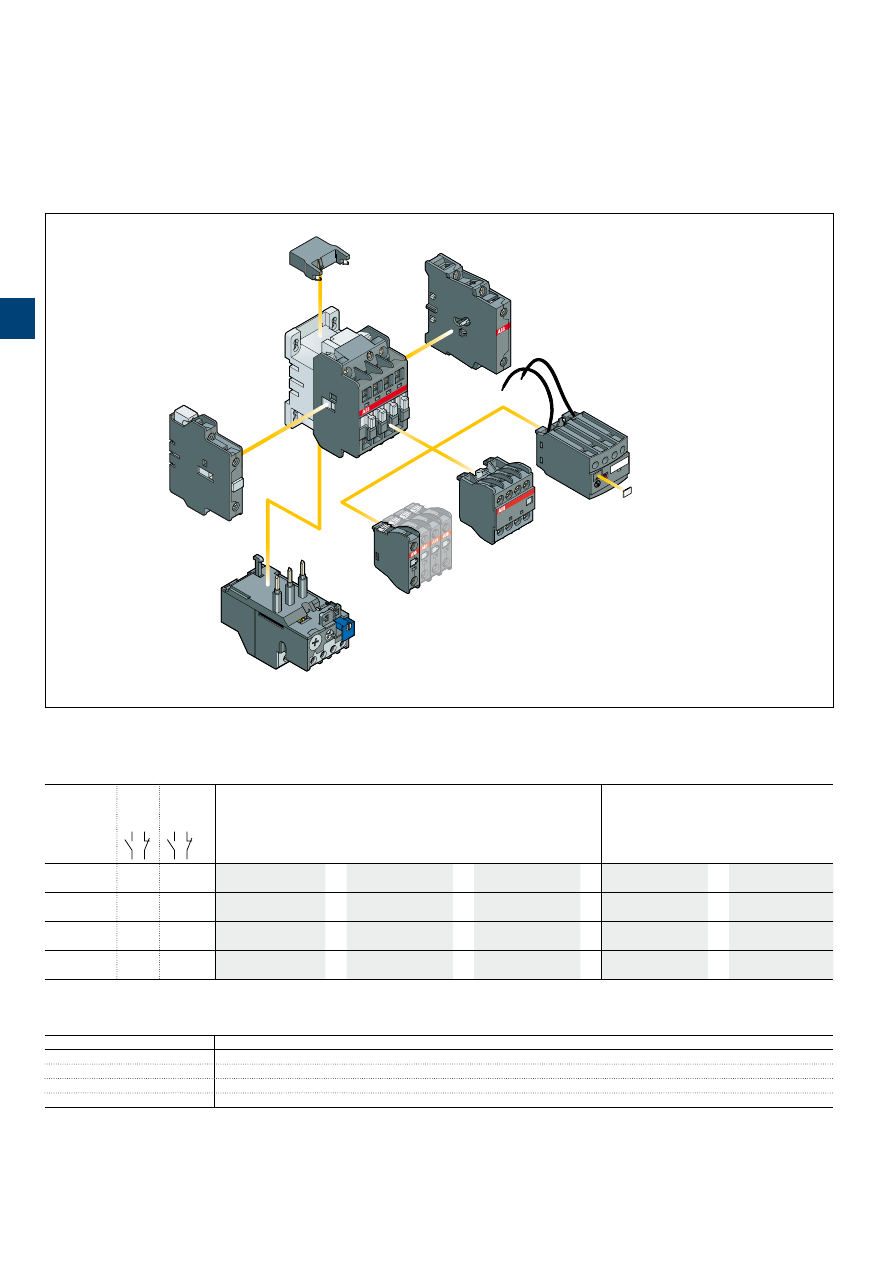

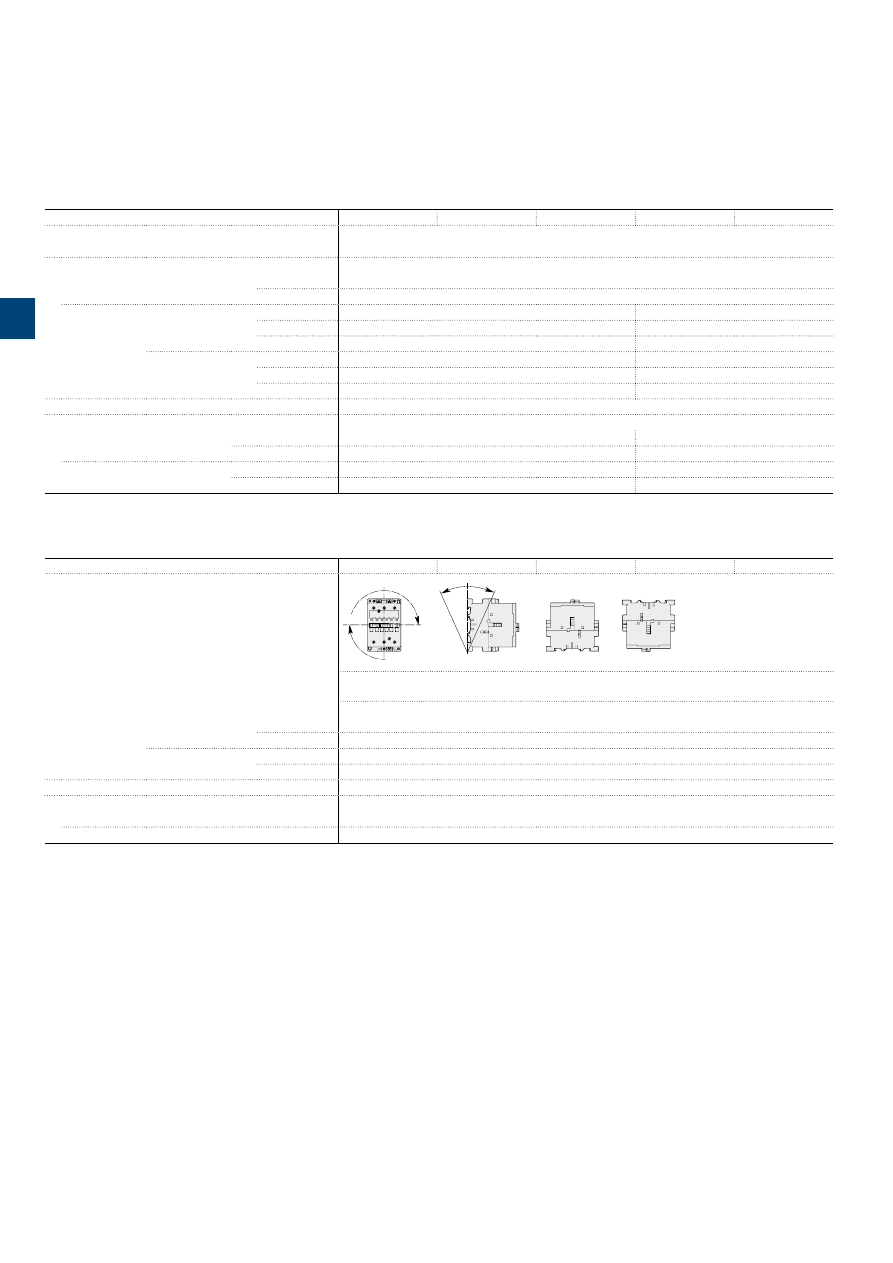

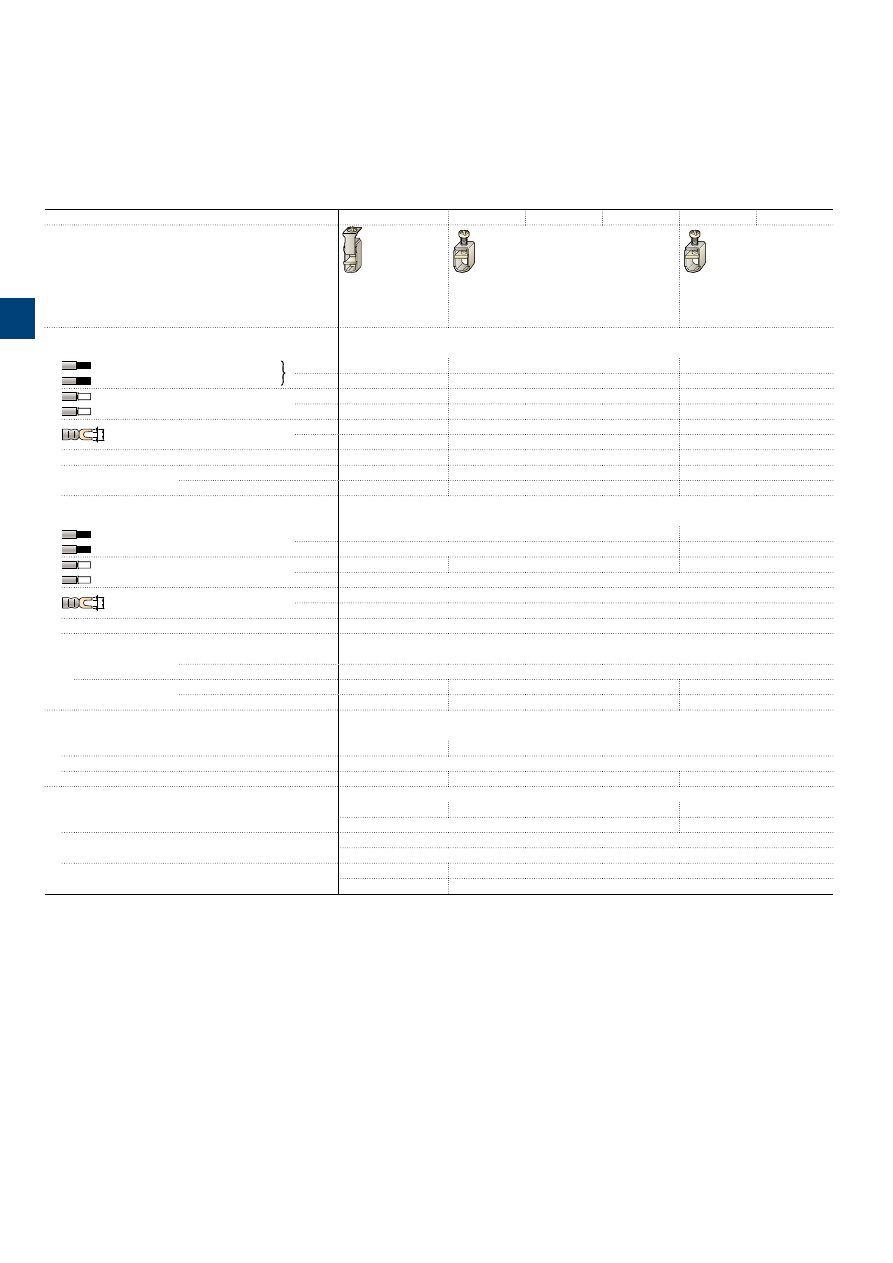

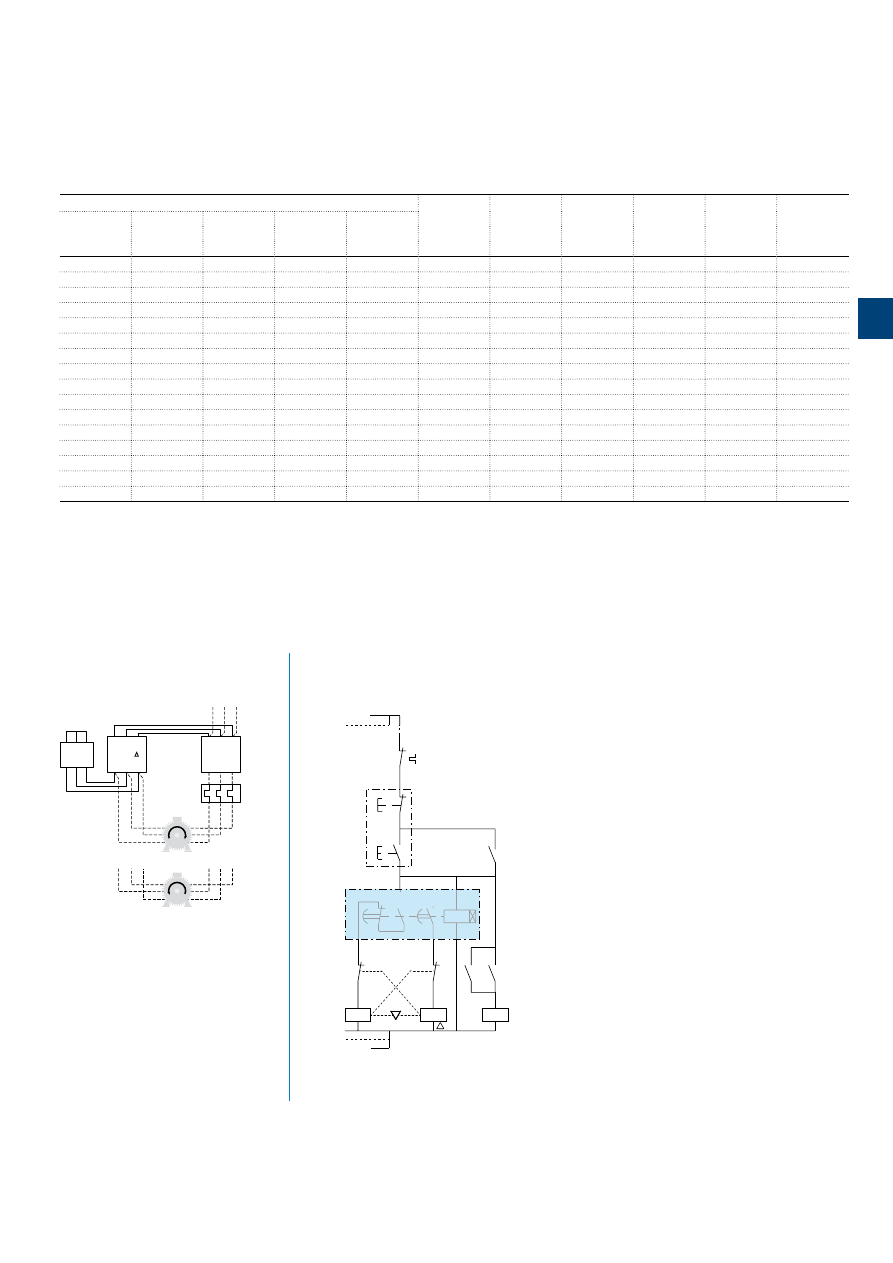

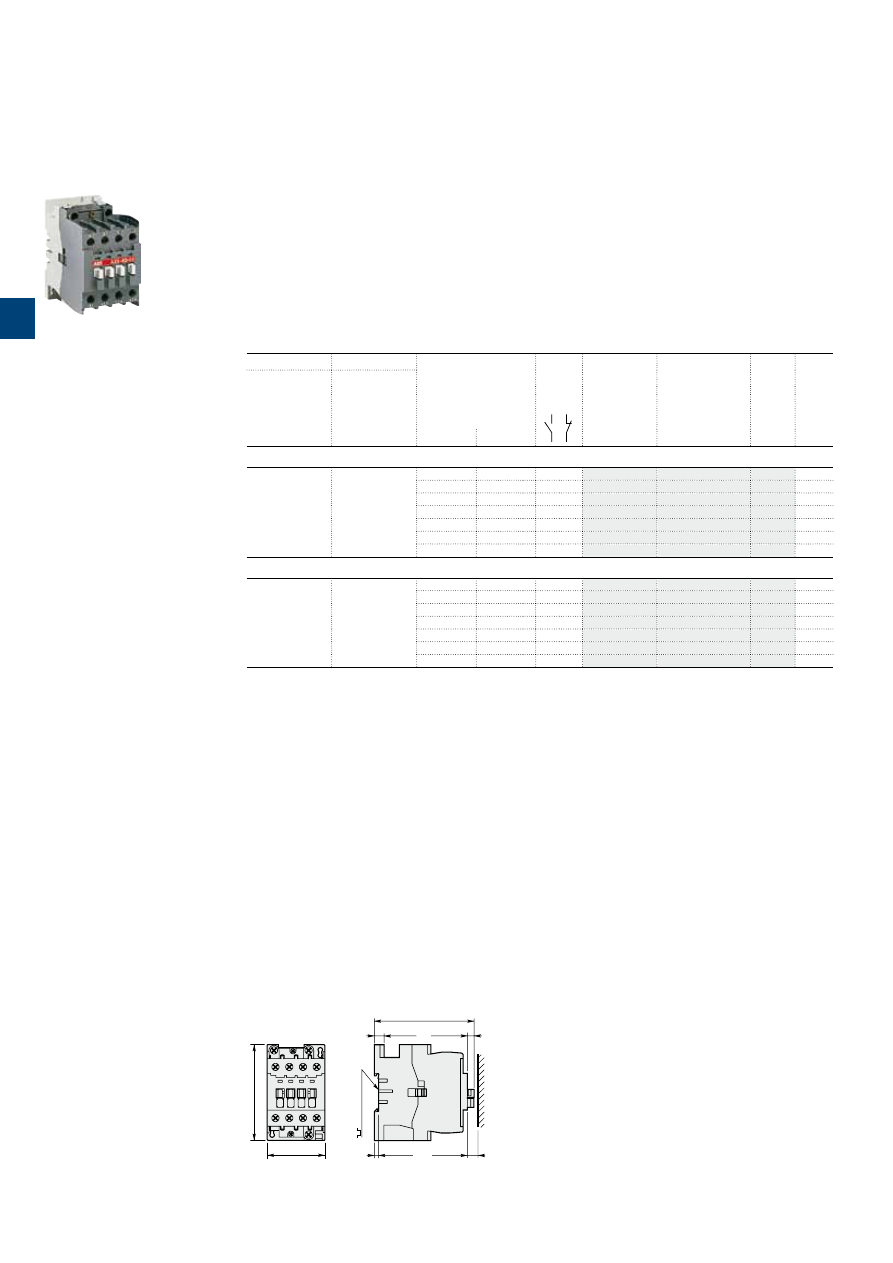

A contactors and N contactor relays

Connect to

You can access to more product details, click on the order code

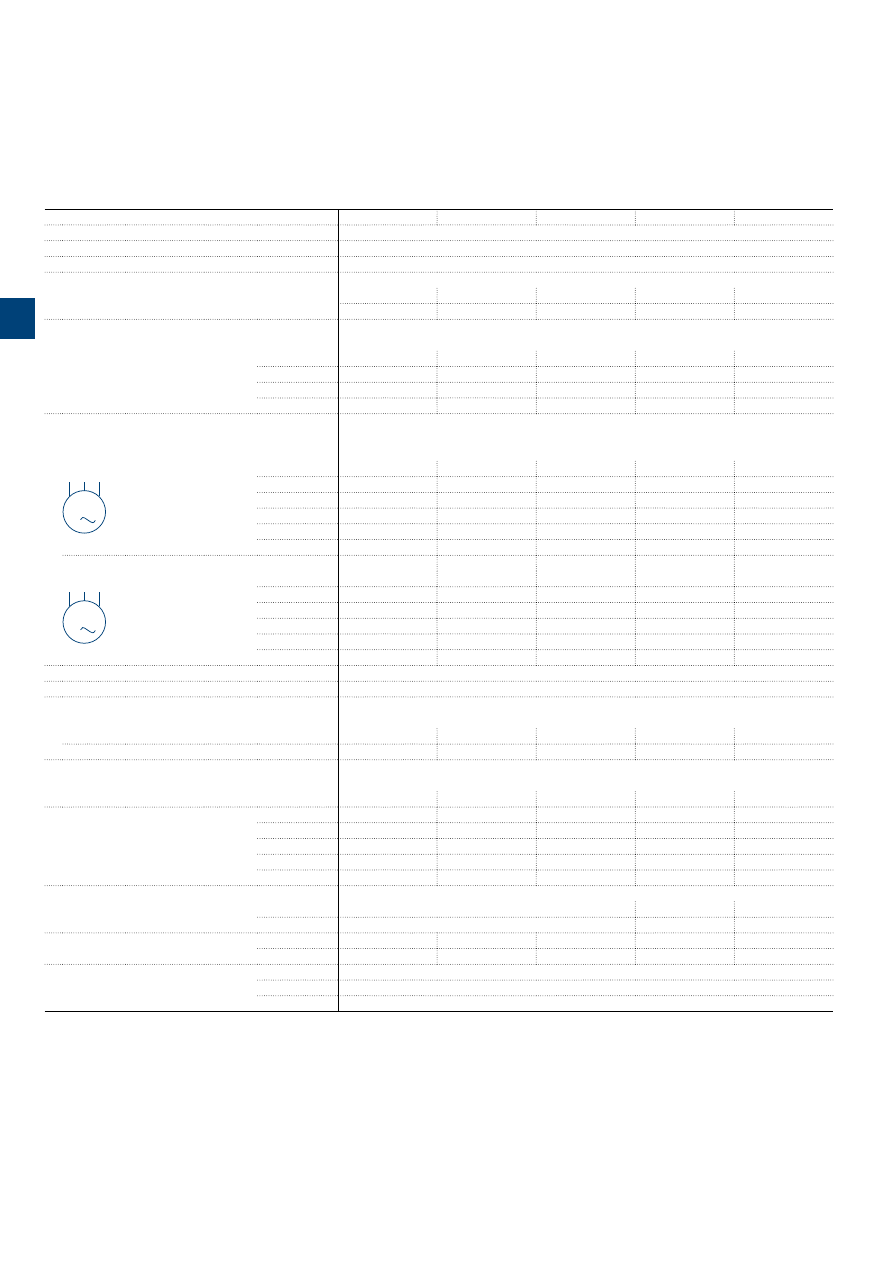

IEC

(1)

AC-3 Rated operational power

θ

≤ 55 °C, 400 V

kW

4

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

110

140

160

UL/CSA 3-phase motor rating

480 V

hp

5

7.5

10

20

25

30

40

60

60

60

75

100

125

150

200

250

AC Control supply

Type

A9

A12

A16

A26

A30

A40

A50

A63

A75

A95

A110

A145

A185

A210

A260

A300

IEC

AC-3 Rated operational current

θ

≤ 55 °C , 400 V

A

9

12

17

26

32

37

50

65

75

96

110

145

185

210

260

305

AC-1 Rated operational current

θ

≤ 40 °C, 690 V

A

25

27

30

45

55

60

100

115

125

145

160

250

275

350

400

500

UL/CSA General use rating

600 V

A

21

25

30

40

50

60

80

90

105

125

150

230

250

300

350

400

NEMA

NEMA Size

00

0

—

1

1P

—

2

—

3

—

—

4

—

—

5

—

(1) 1000 V IEC ratings available for A50 ... A300 contactors.

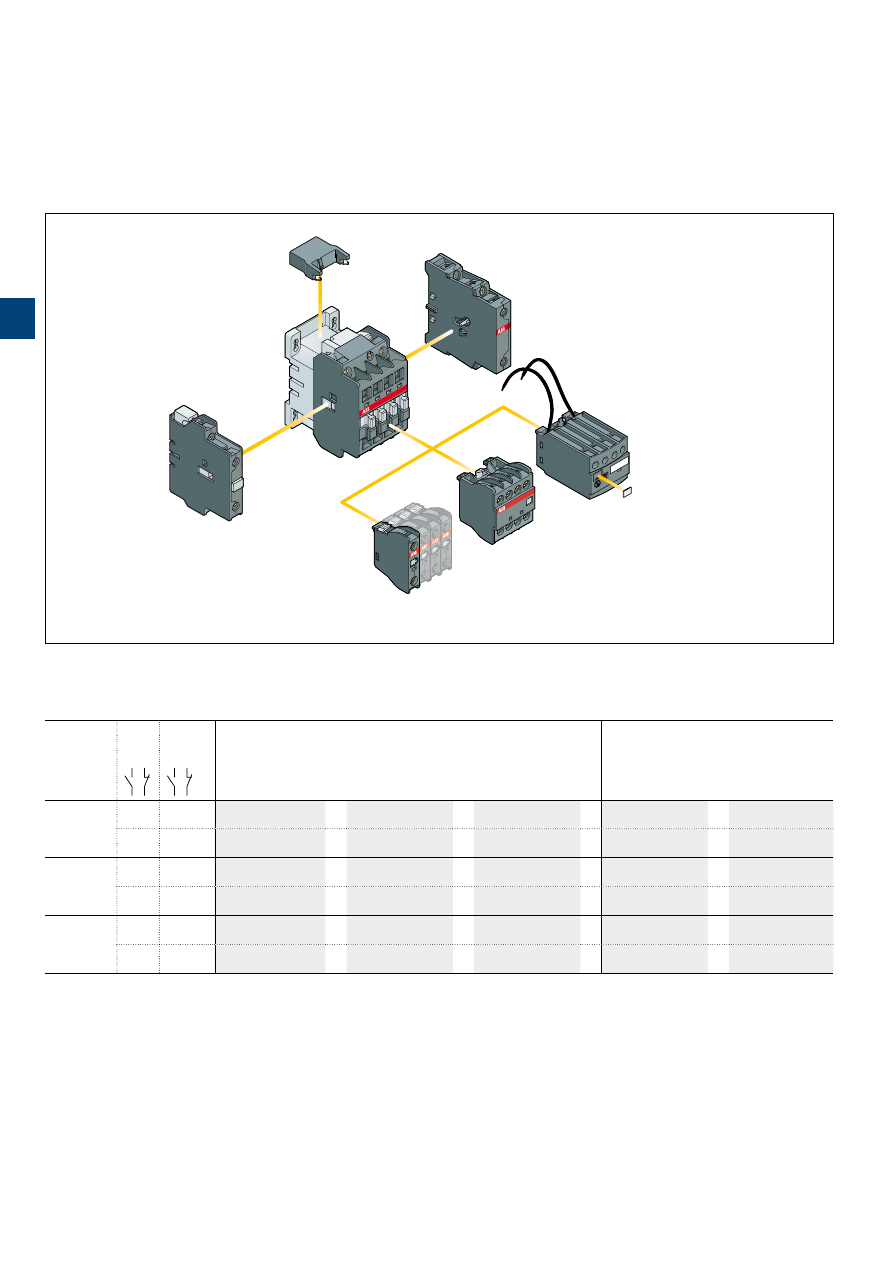

Main accessories

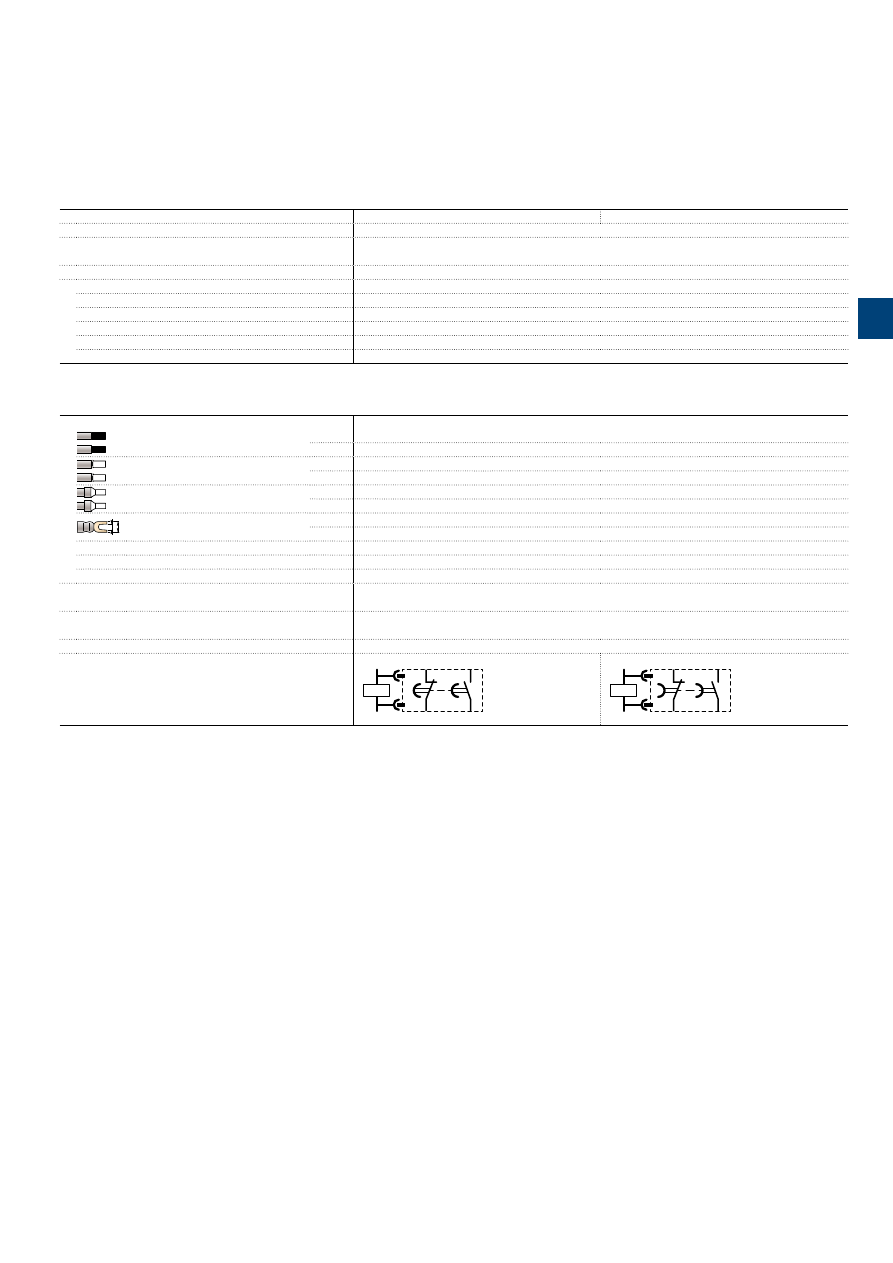

Auxiliary contact blocks

Front mounting

CA5-10

(1 x N.O.)

CA5-01

(1 x N.C.)

Side mounting

CAL5-11

(1 x N.O. + 1 x N.C.)

CAL18-11

(1 x N.O. + 1 x N.C.)

Timers

Electronic

TEF5-ON

TEF5-OFF

TE5S

(for star-delta starters - direct timing - separate mounting)

Interlocking units

Mechanical

VM5-1

VM300H

VM300V

Mechanical / Electrical

VE5-1

VE5-2

Surge suppressors

Varistor (AC/DC)

RV5

(24...440 V)

RC Type (AC)

RC5-1

(24...440 V)

RC5-2

(24...440 V)

RC5-3

(250...440 V)

Overload relays

Thermal relays

Class 10A

(Class 10A or 20 for TA80DU)

(Class 30 for TA450SU)

TA25DU-M

(0.10…32 A)

TA75DU-M

(18…80 A)

TA80DU

(29...80 A)

TA200DU

(66...200 A)

TA450DU

(130...310 A)

TA42DU-M

(18…42 A)

TA110DU

(66...110 A)

TA450SU

(40...310 A)

Manual motor starters

Short-circuit protection devices

Thermal / magnetic protection

Class 10

MS116

(0.10...32 A)

lcs up to 50 kA for class 10 A

MS450

(28...50 A)

lcs up to 50 kA

Tmax

Circuit breaker and accessories

MS132

(0.10...32 A)

lcs up to 100 kA

MS495

(45…100 A)

Ics up to 50 kA

MS497

(22…100 A)

Ics up to 100 kA

Magnetic only types

MO132

(0.16...32 A)

Ics up to 100 kA

MO496

(32…100 A)

Ics up to 100 kA

MO450

(40…50 A)

Ics up to 50 kA

MO495

(63…100 A)

Ics up to 50 kA

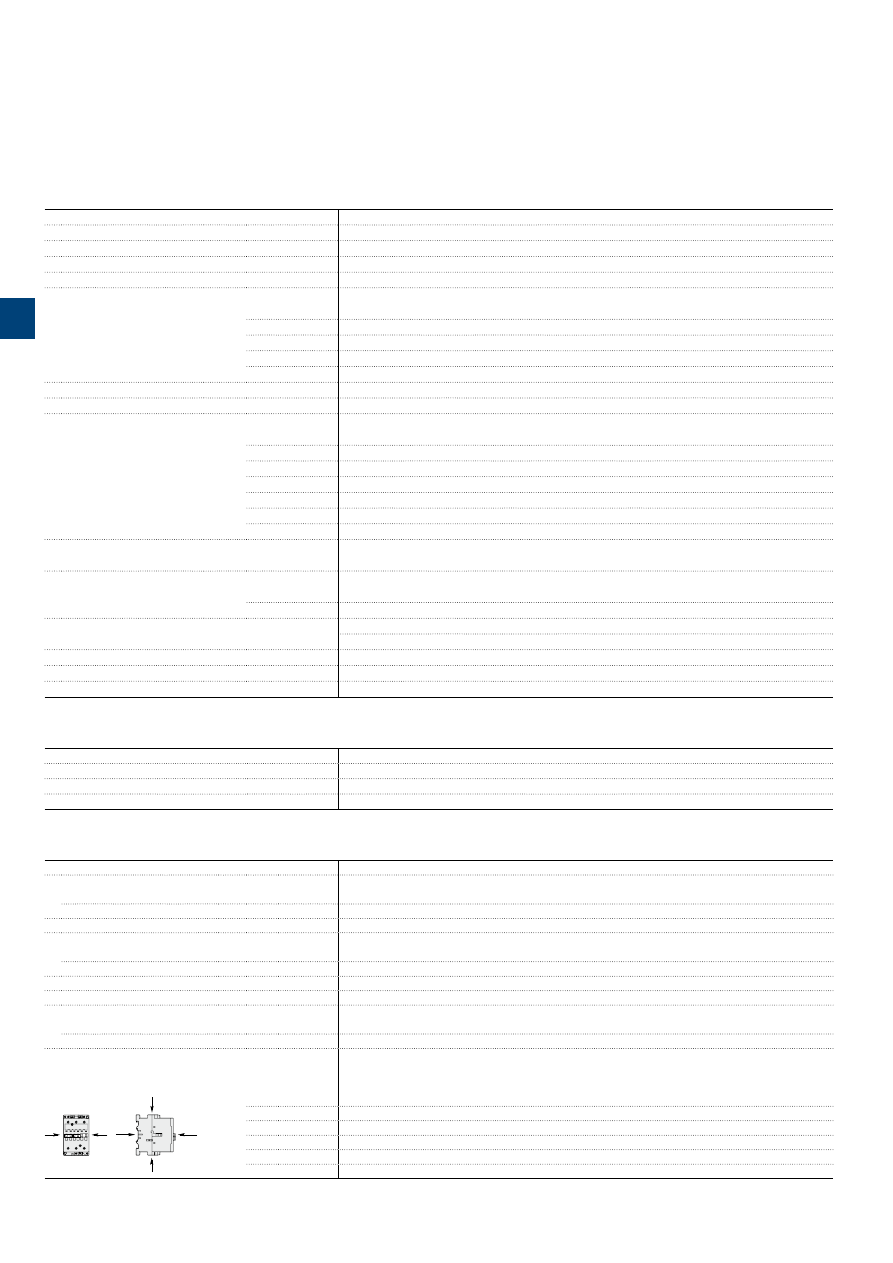

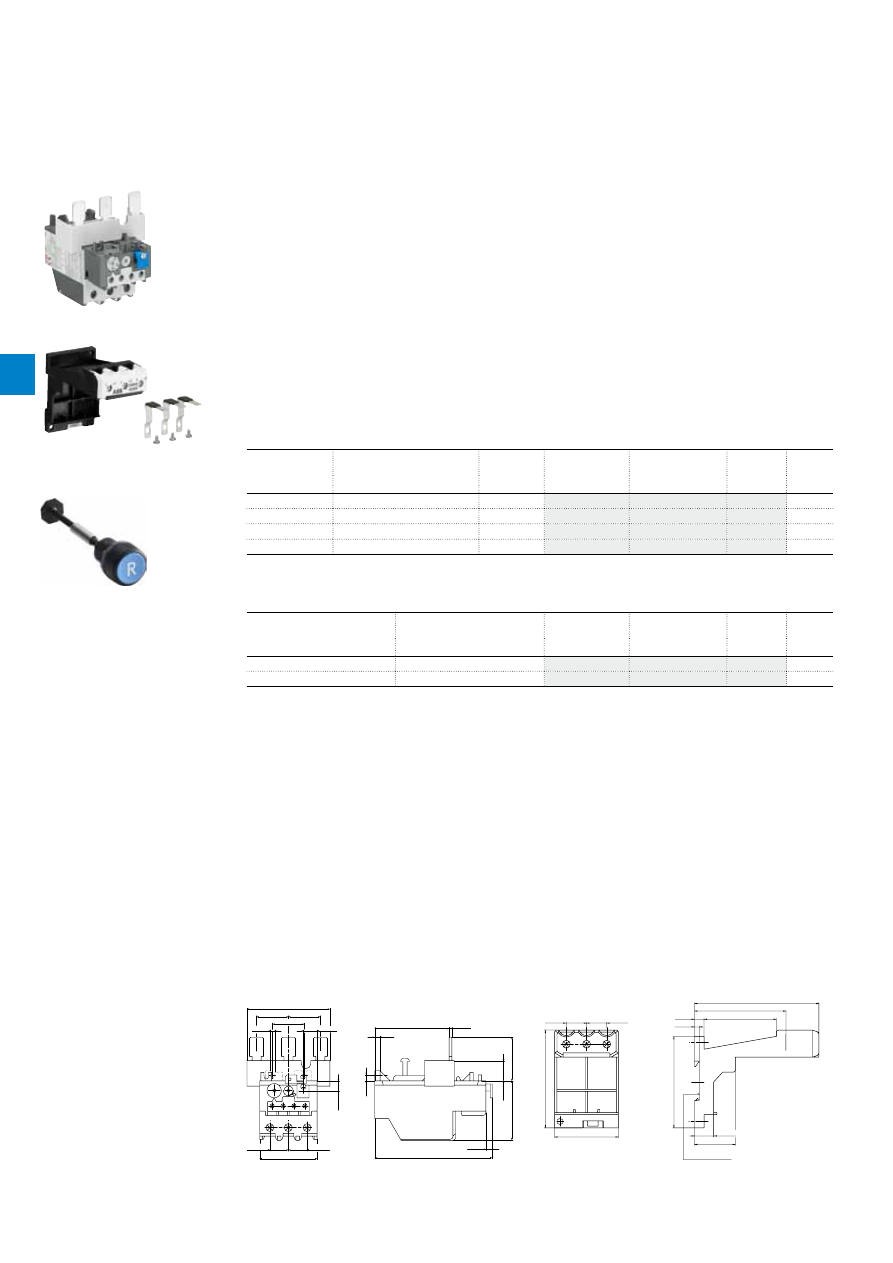

3-pole contactors, for motor control and power switching

1

/2 |

ABB

1

IEC

(1)

AC-3 Rated operational power

θ

≤ 55 °C, 400 V

kW

4

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

110

140

160

UL/CSA 3-phase motor rating

480 V

hp

5

7.5

10

20

25

30

40

60

60

60

75

100

125

150

200

250

AC Control supply

Type

A9

A12

A16

A26

A30

A40

A50

A63

A75

A95

A110

A145

A185

A210

A260

A300

IEC

AC-3 Rated operational current

θ

≤ 55 °C , 400 V

A

9

12

17

26

32

37

50

65

75

96

110

145

185

210

260

305

AC-1 Rated operational current

θ

≤ 40 °C, 690 V

A

25

27

30

45

55

60

100

115

125

145

160

250

275

350

400

500

UL/CSA General use rating

600 V

A

21

25

30

40

50

60

80

90

105

125

150

230

250

300

350

400

NEMA

NEMA Size

00

0

—

1

1P

—

2

—

3

—

—

4

—

—

5

—

(1) 1000 V IEC ratings available for A50 ... A300 contactors.

Main accessories

Auxiliary contact blocks

Front mounting

CA5-10

(1 x N.O.)

CA5-01

(1 x N.C.)

Side mounting

CAL5-11

(1 x N.O. + 1 x N.C.)

CAL18-11

(1 x N.O. + 1 x N.C.)

Timers

Electronic

TEF5-ON

TEF5-OFF

TE5S

(for star-delta starters - direct timing - separate mounting)

Interlocking units

Mechanical

VM5-1

VM300H

VM300V

Mechanical / Electrical

VE5-1

VE5-2

Surge suppressors

Varistor (AC/DC)

RV5

(24...440 V)

RC Type (AC)

RC5-1

(24...440 V)

RC5-2

(24...440 V)

RC5-3

(250...440 V)

Overload relays

Thermal relays

Class 10A

(Class 10A or 20 for TA80DU)

(Class 30 for TA450SU)

TA25DU-M

(0.10…32 A)

TA75DU-M

(18…80 A)

TA80DU

(29...80 A)

TA200DU

(66...200 A)

TA450DU

(130...310 A)

TA42DU-M

(18…42 A)

TA110DU

(66...110 A)

TA450SU

(40...310 A)

Manual motor starters

Short-circuit protection devices

Thermal / magnetic protection

Class 10

MS116

(0.10...32 A)

lcs up to 50 kA for class 10 A

MS450

(28...50 A)

lcs up to 50 kA

Tmax

Circuit breaker and accessories

MS132

(0.10...32 A)

lcs up to 100 kA

MS495

(45…100 A)

Ics up to 50 kA

MS497

(22…100 A)

Ics up to 100 kA

Magnetic only types

MO132

(0.16...32 A)

Ics up to 100 kA

MO496

(32…100 A)

Ics up to 100 kA

MO450

(40…50 A)

Ics up to 50 kA

MO495

(63…100 A)

Ics up to 50 kA

1S

B

C

101

87

5

S

0

2

01

ABB

|

1

/3

1

1

/4 |

ABB

N3

1

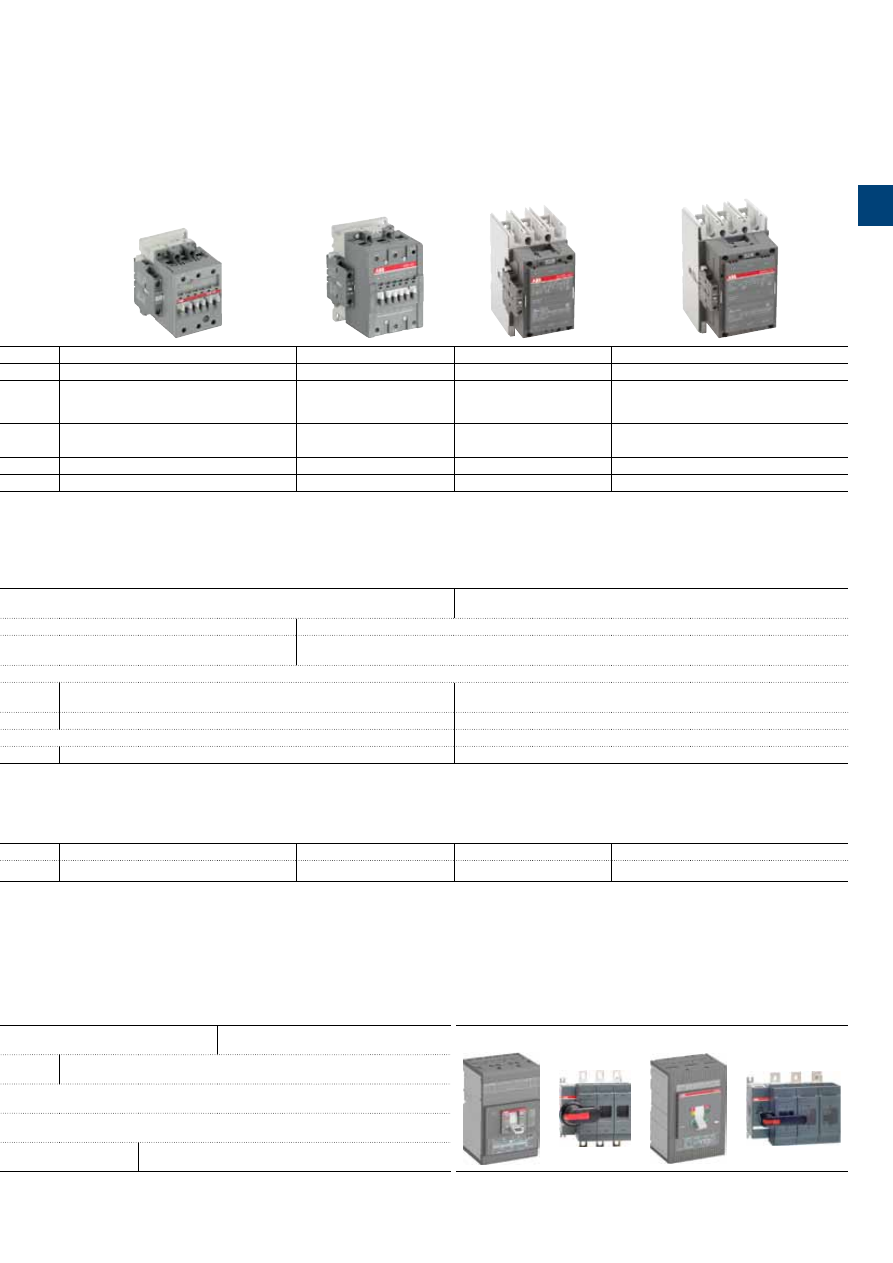

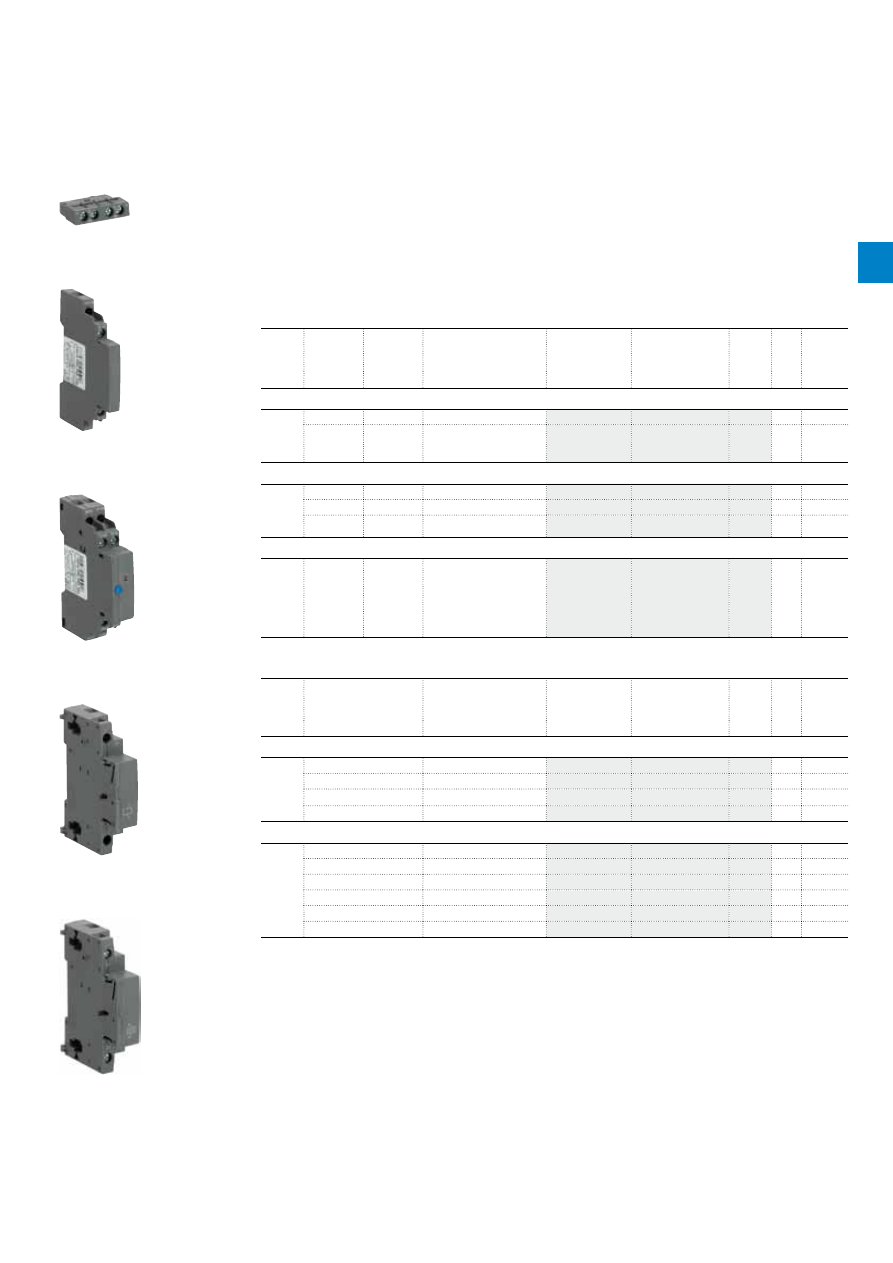

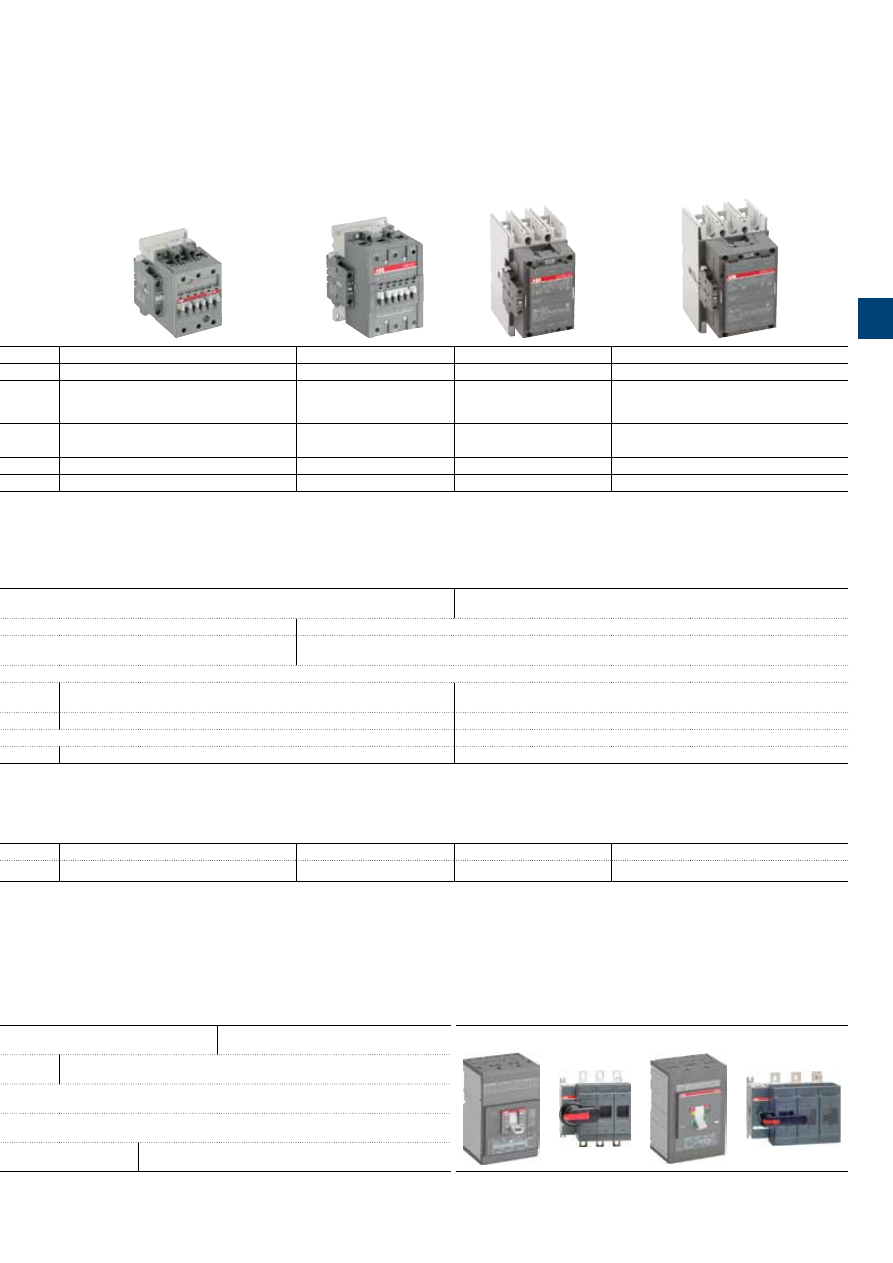

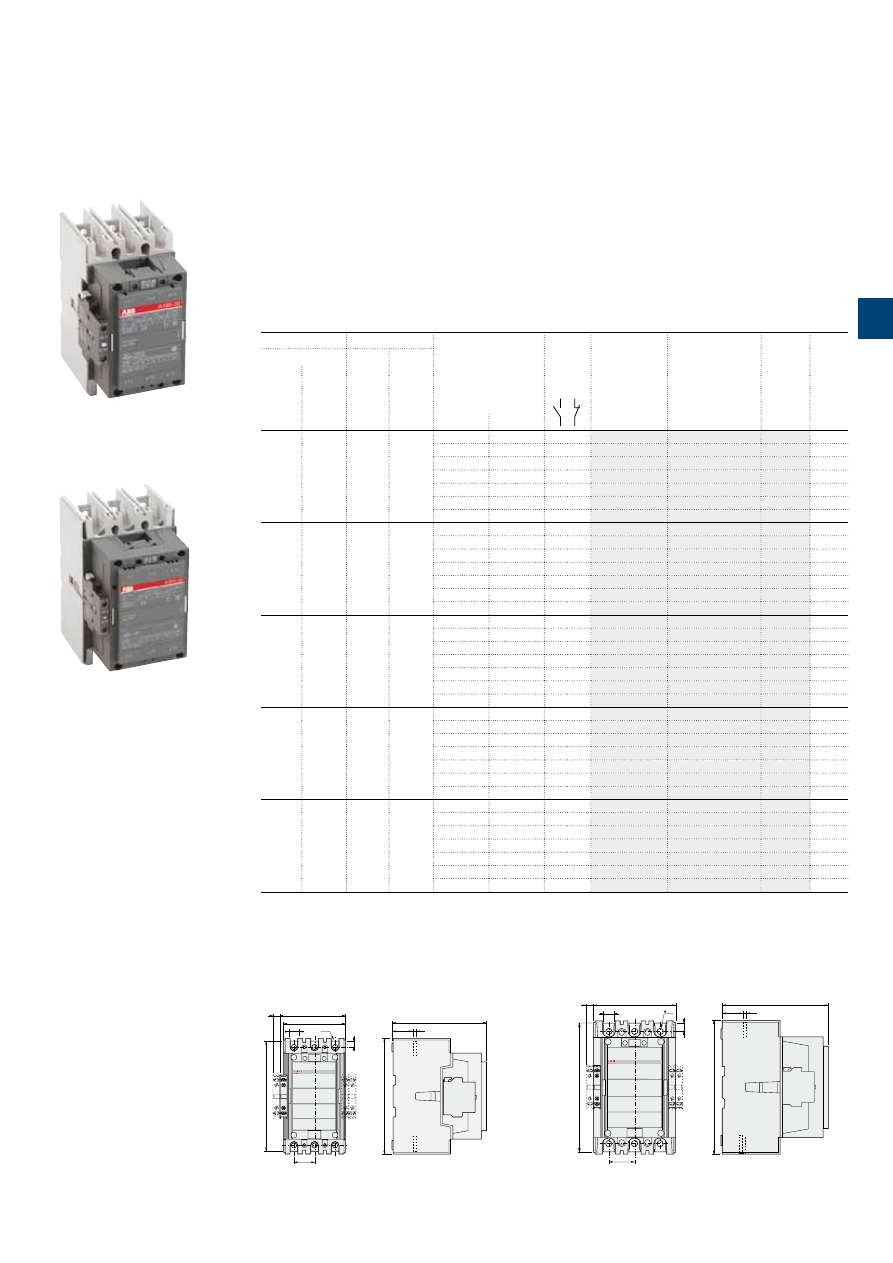

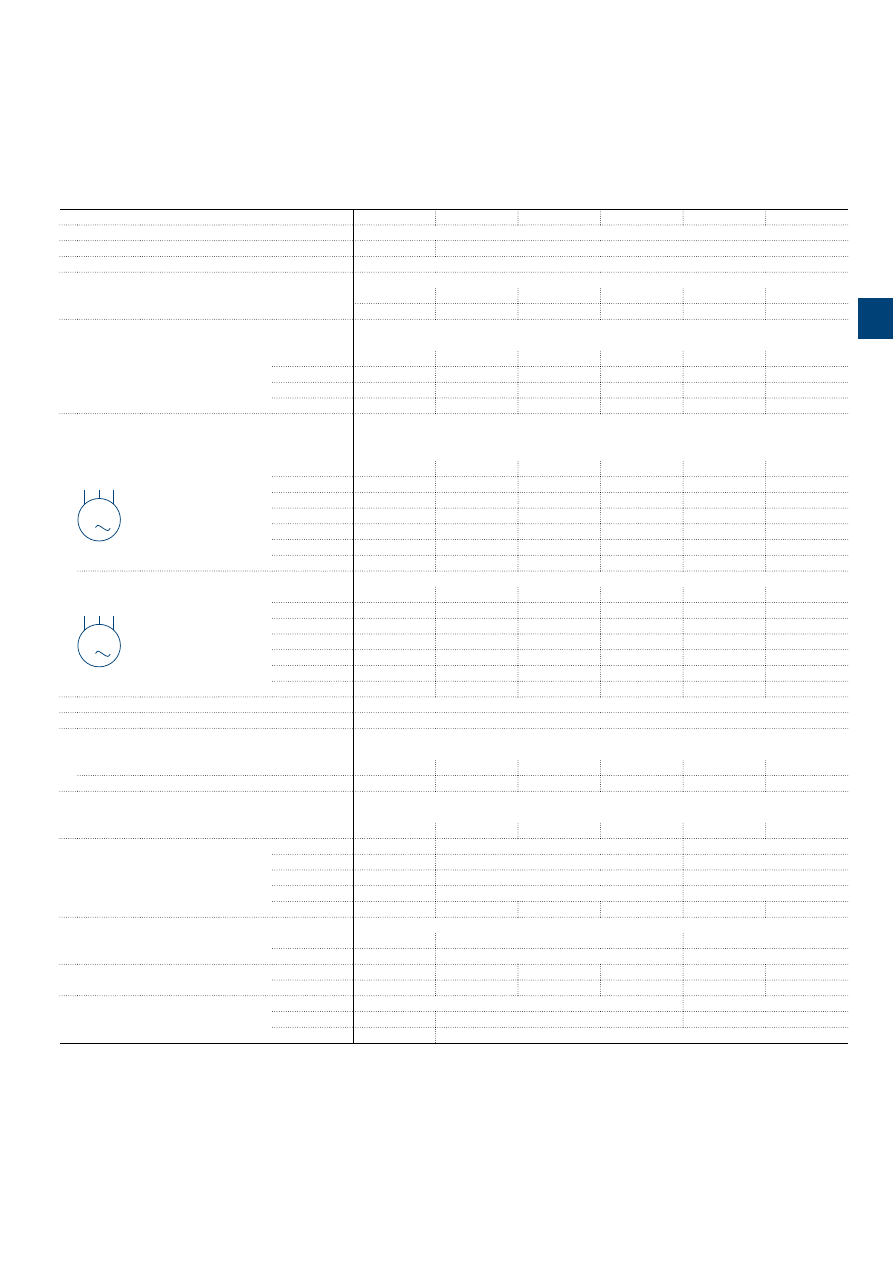

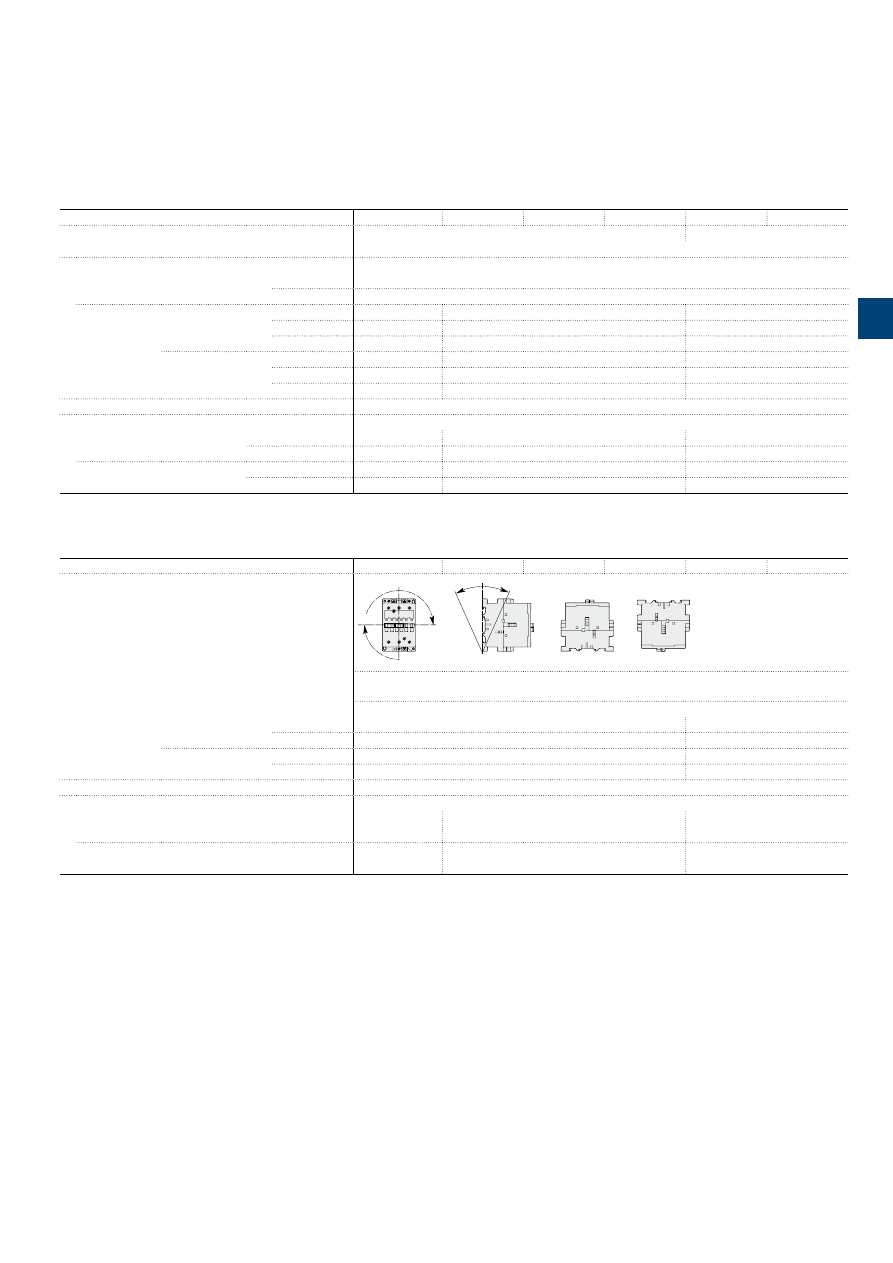

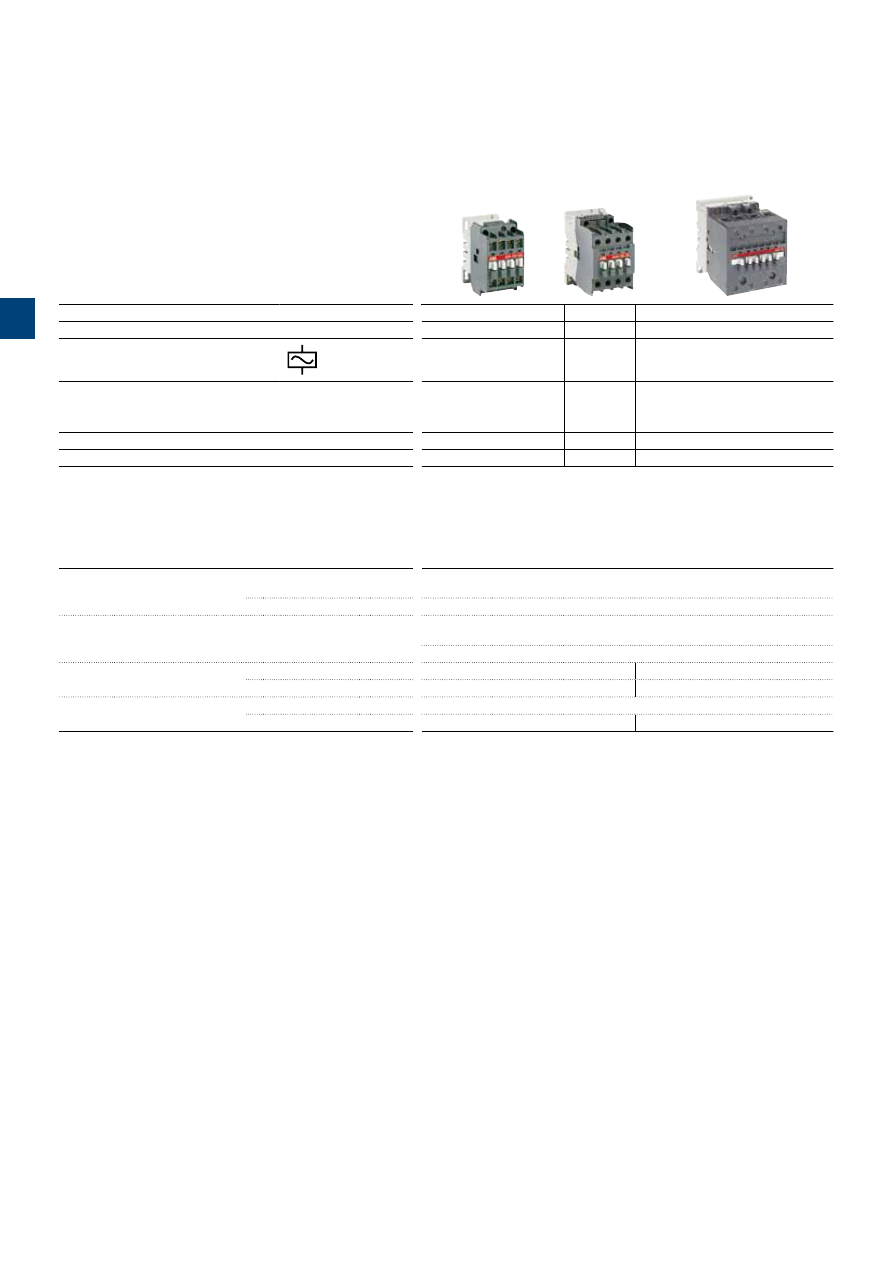

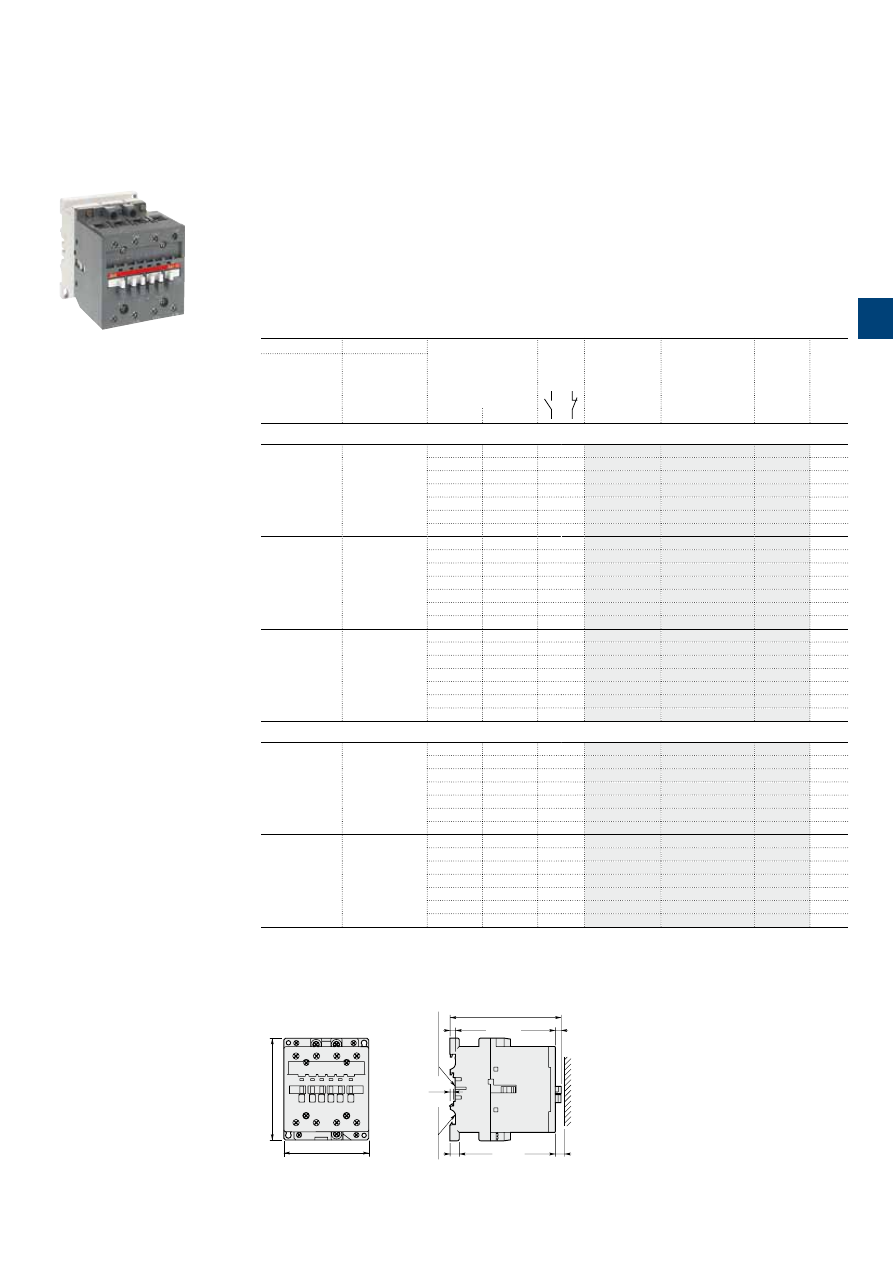

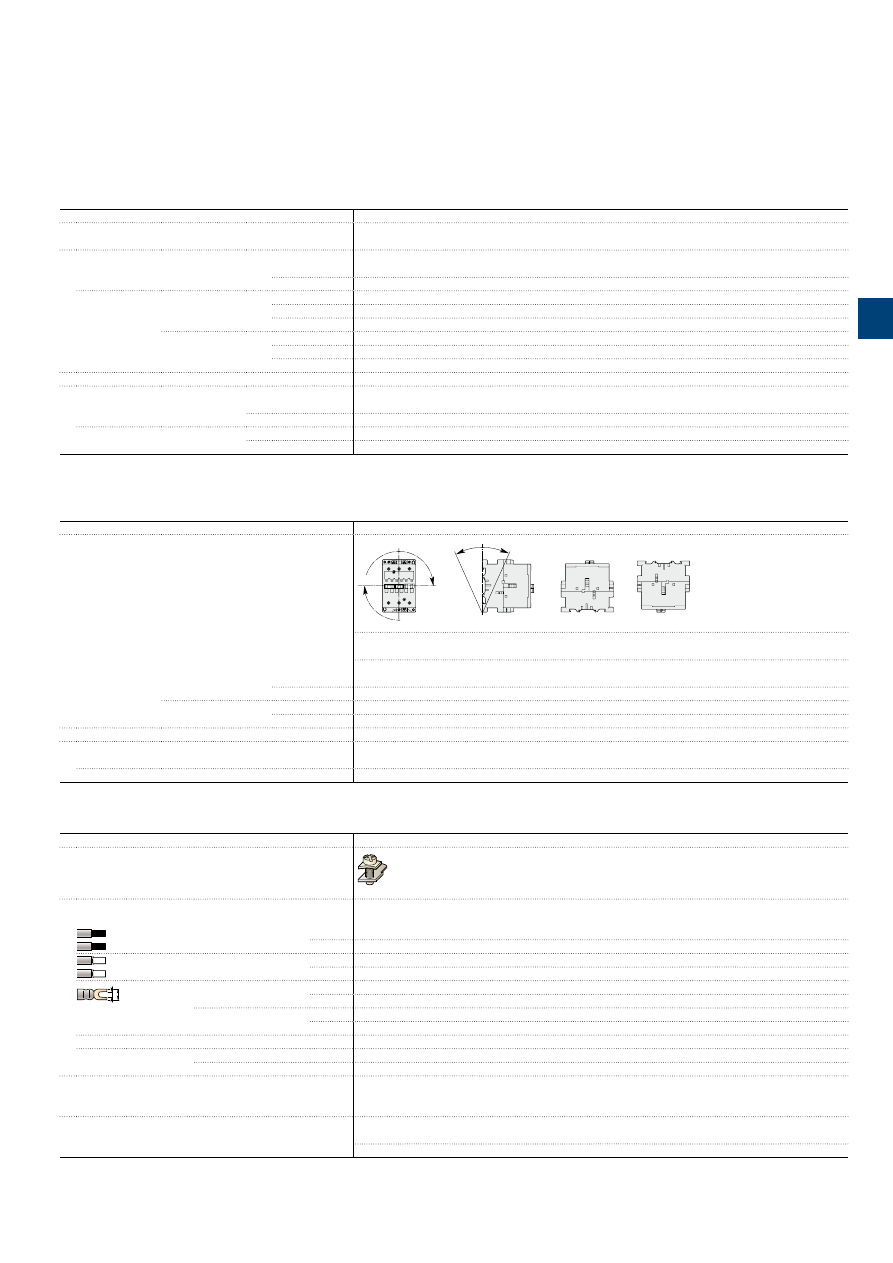

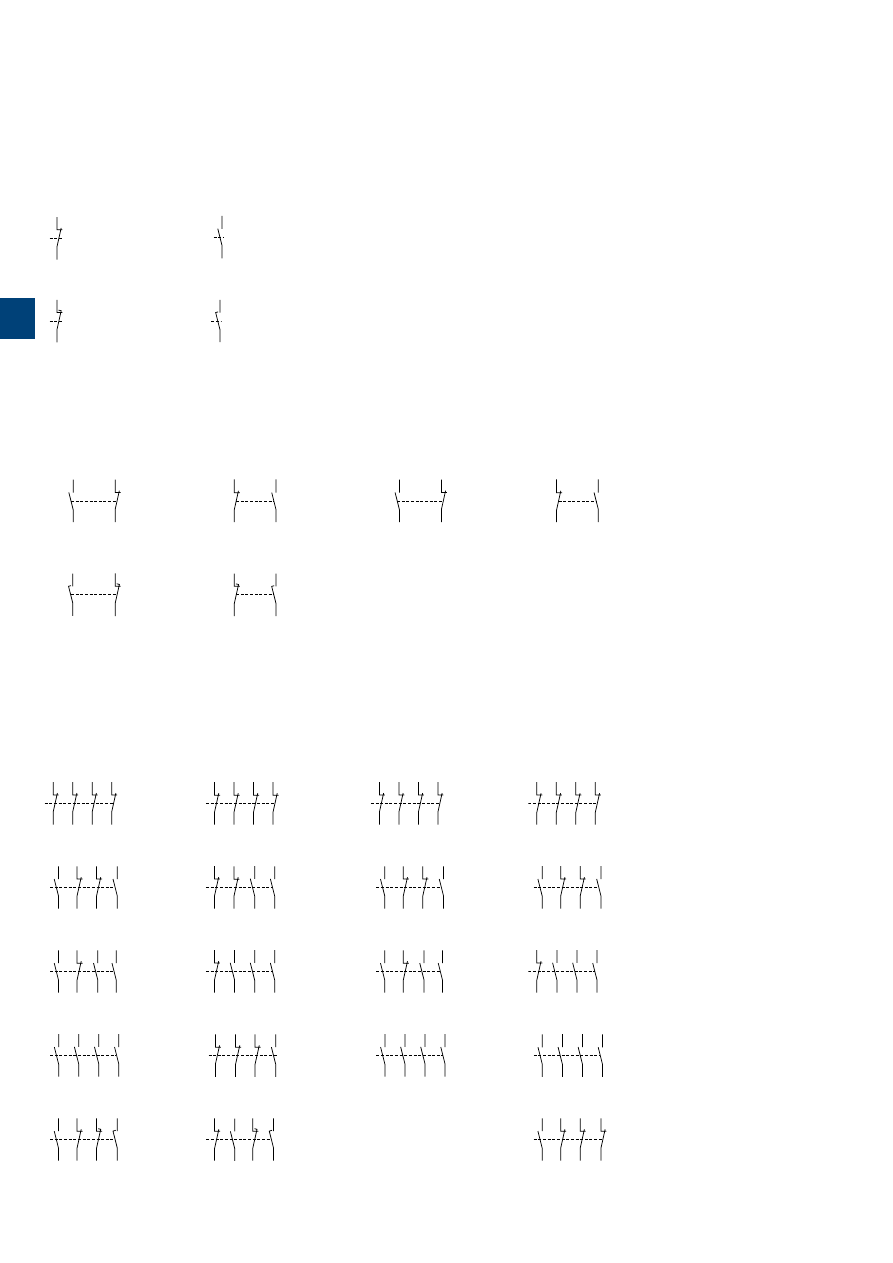

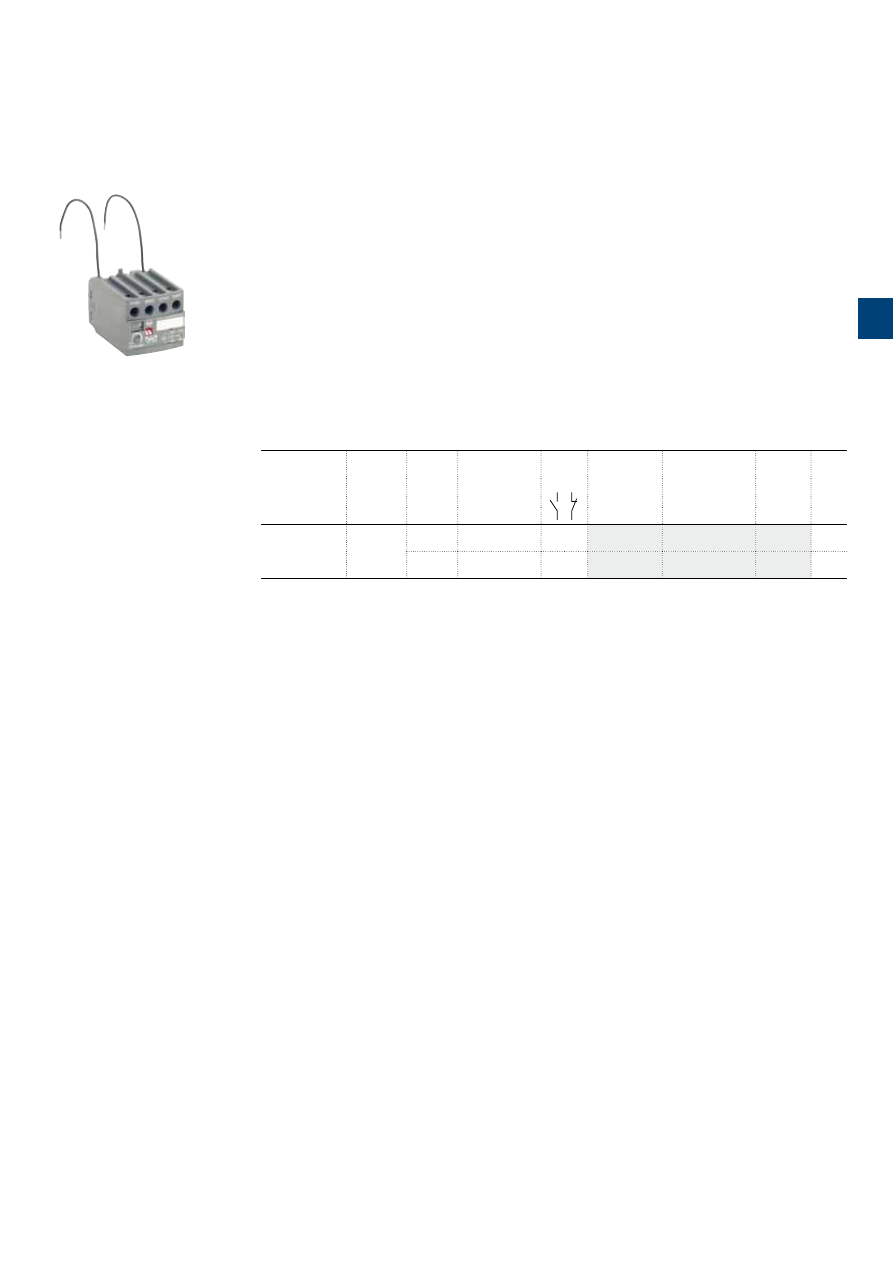

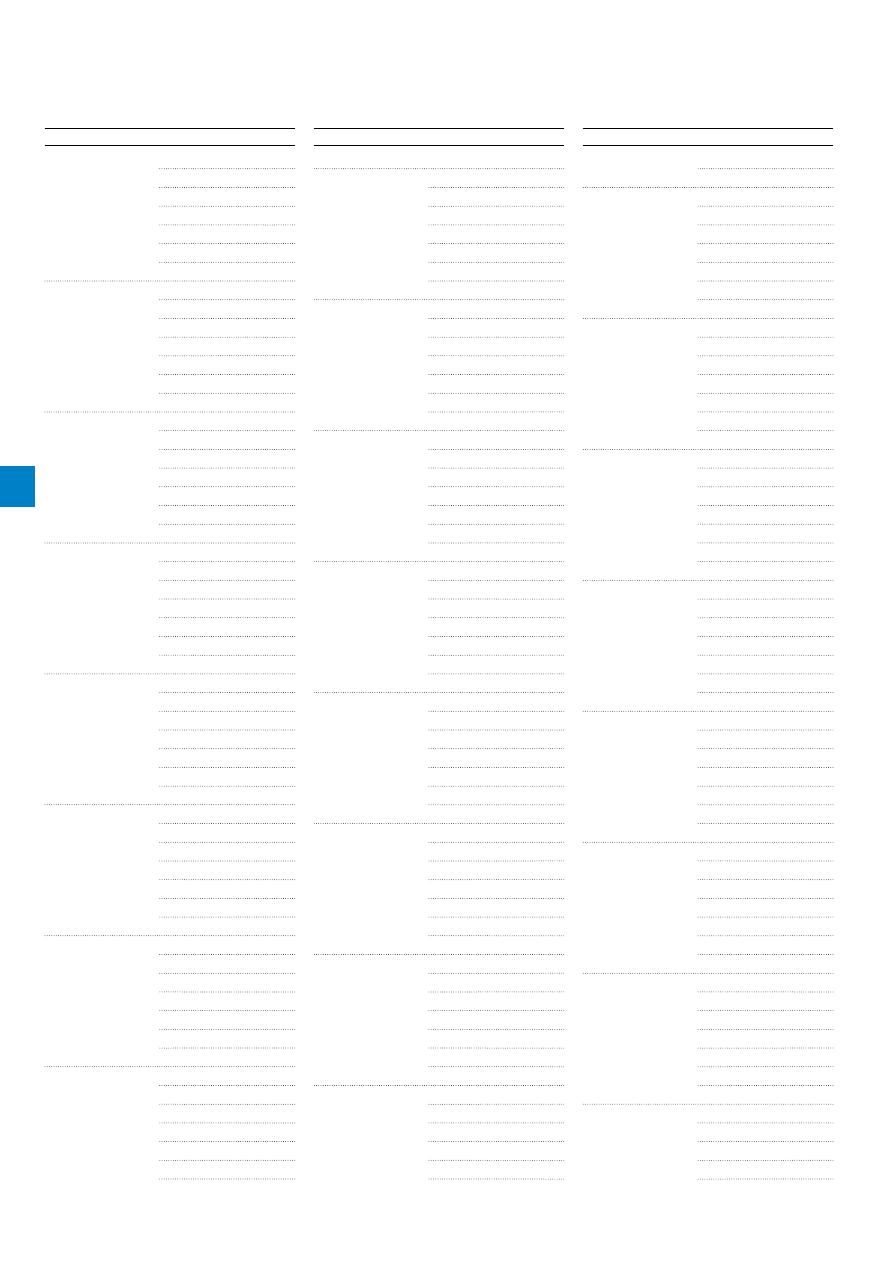

4-pole contactors

IEC

AC-1 Rated operational current

θ

≤ 40 °C, 690 V

A

25

30

45

70

100

125

UL/CSA General use rating

600 V

A

21

30

40

65

80

105

AC Control supply

Type

A9

A16

A26

A45

A50

A75

IEC

AC-1 Rated operational current

θ

≤ 40 °C

A

25

30

45

70

100

125

θ

≤ 55 °C

A

22

27

40

60

85

105

θ

≤ 70 °C

A

18

23

32

50

70

85

With conductor cross sectional area

mm

2

2.5

4

6

25

35

50

Rated operational voltage Ue max.

V

690

690

690

1000

1000

1000

Main accessories

Auxiliary contact blocks

Front mounting

CA5-10

(1 x N.O.)

CA5-01

(1 x N.C.)

Side mounting

CAL5-11

(1 x N.O. + 1 x N.C.)

Timers

Electronic

TEF5-ON

TEF5-OFF

TE5S

(for star-delta starters - direct timing - separate mounting)

Interlocking units

Mechanical

VM5-1

Mechanical / Electrical

VE5-1

VE5-2

Surge suppressors

Varistor (AC / DC)

RV5

(24...440 V)

RC Type (AC)

RC5-1

(24...440 V)

RC5-2

(24...440 V)

1S

B

C

101

8

8

4

S

0

2

01

ABB

|

1

/5

1

S

umma

ry

_2

2

2

/0

| ABB

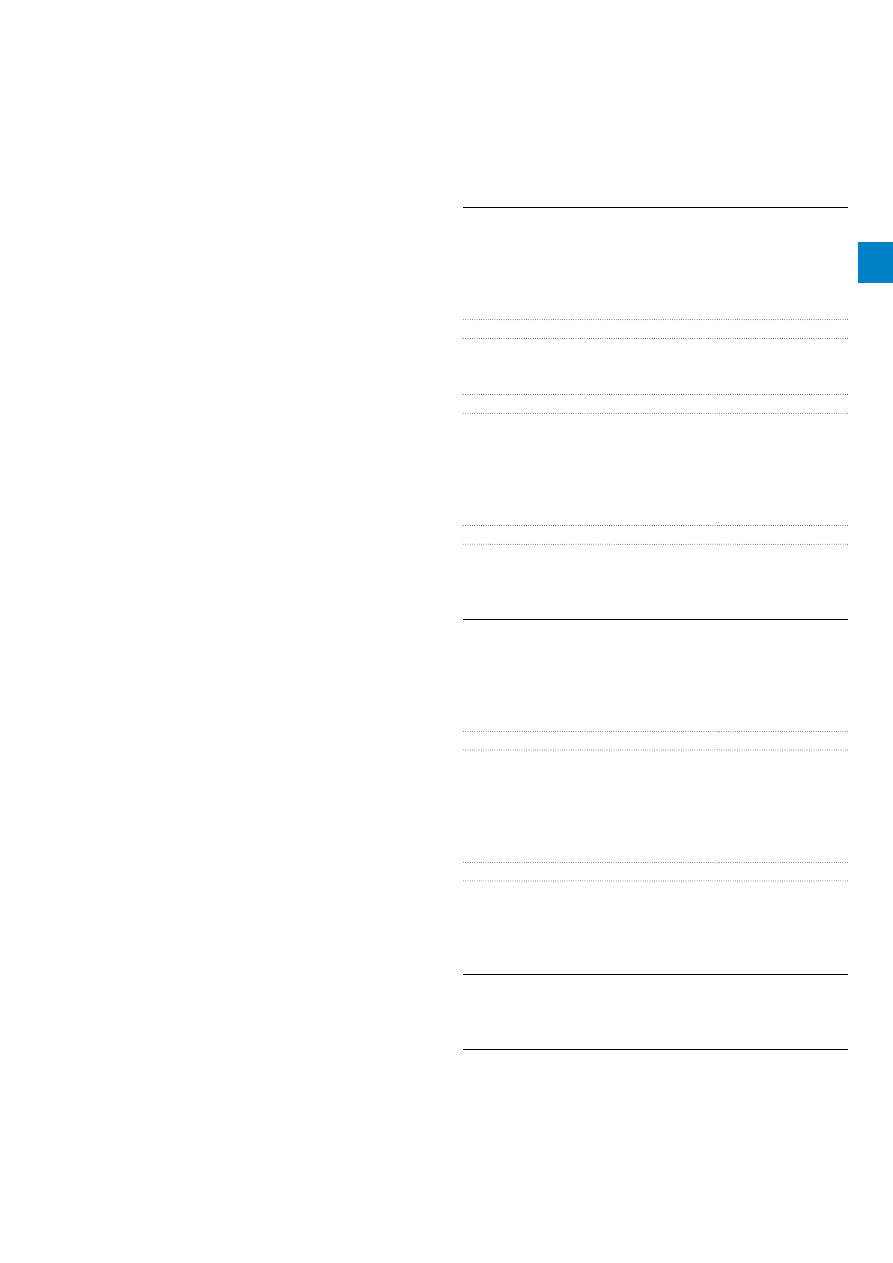

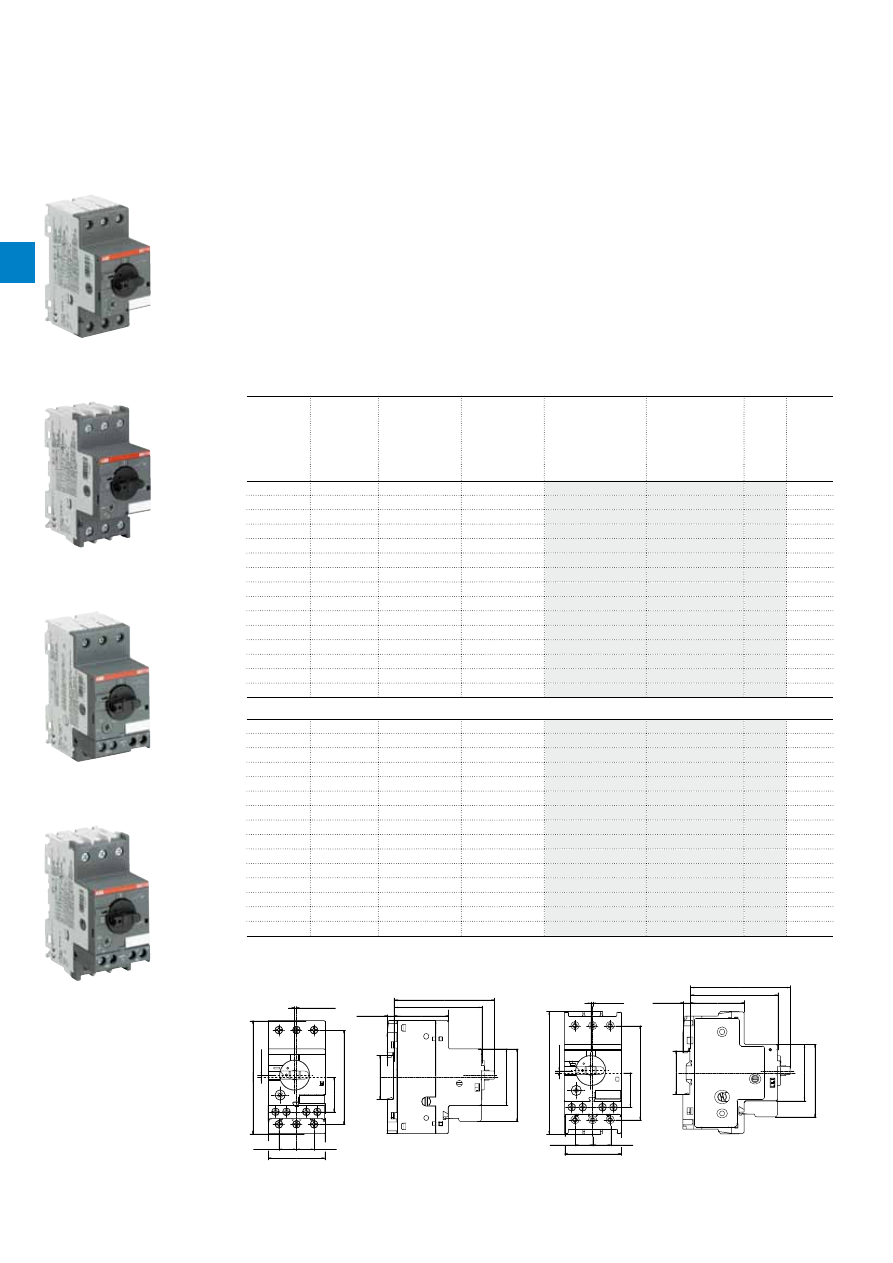

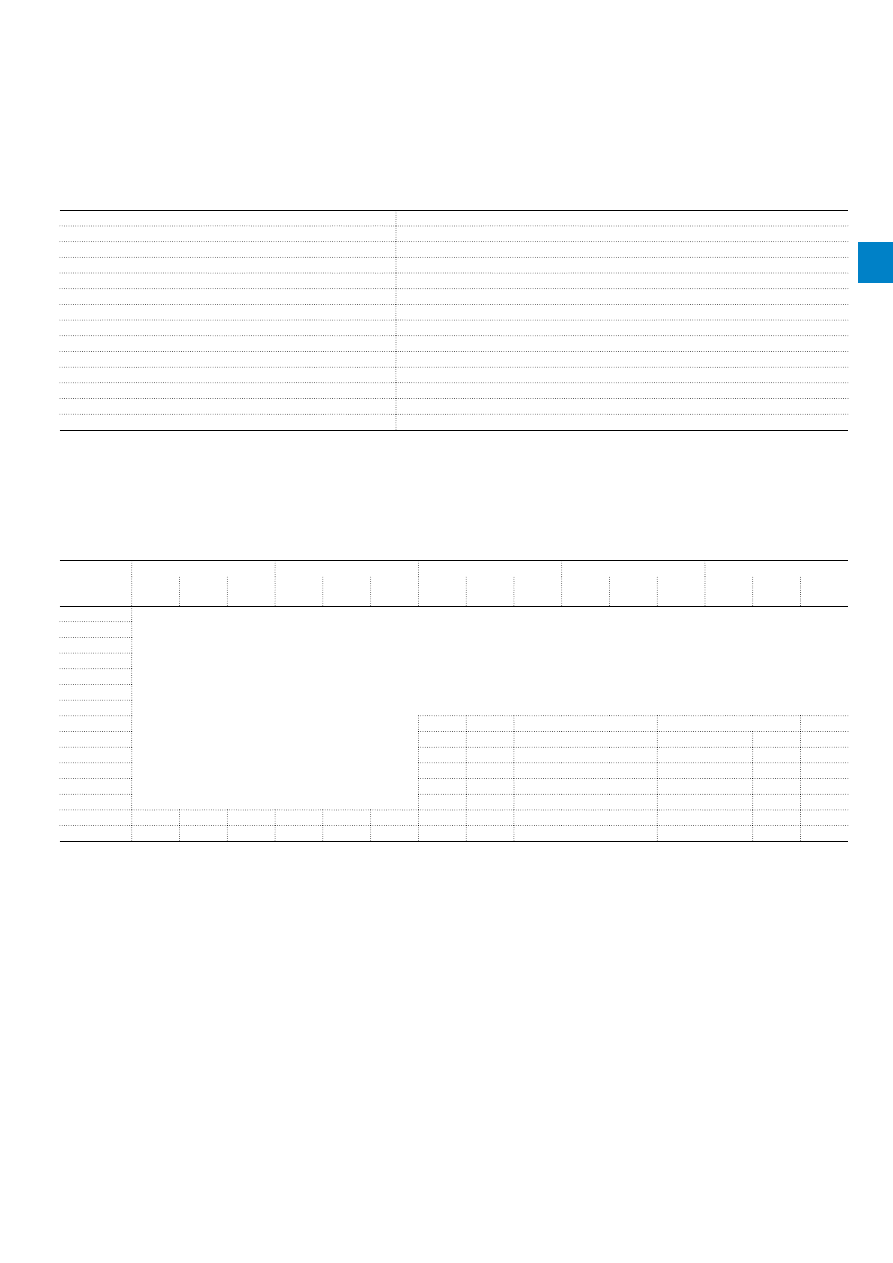

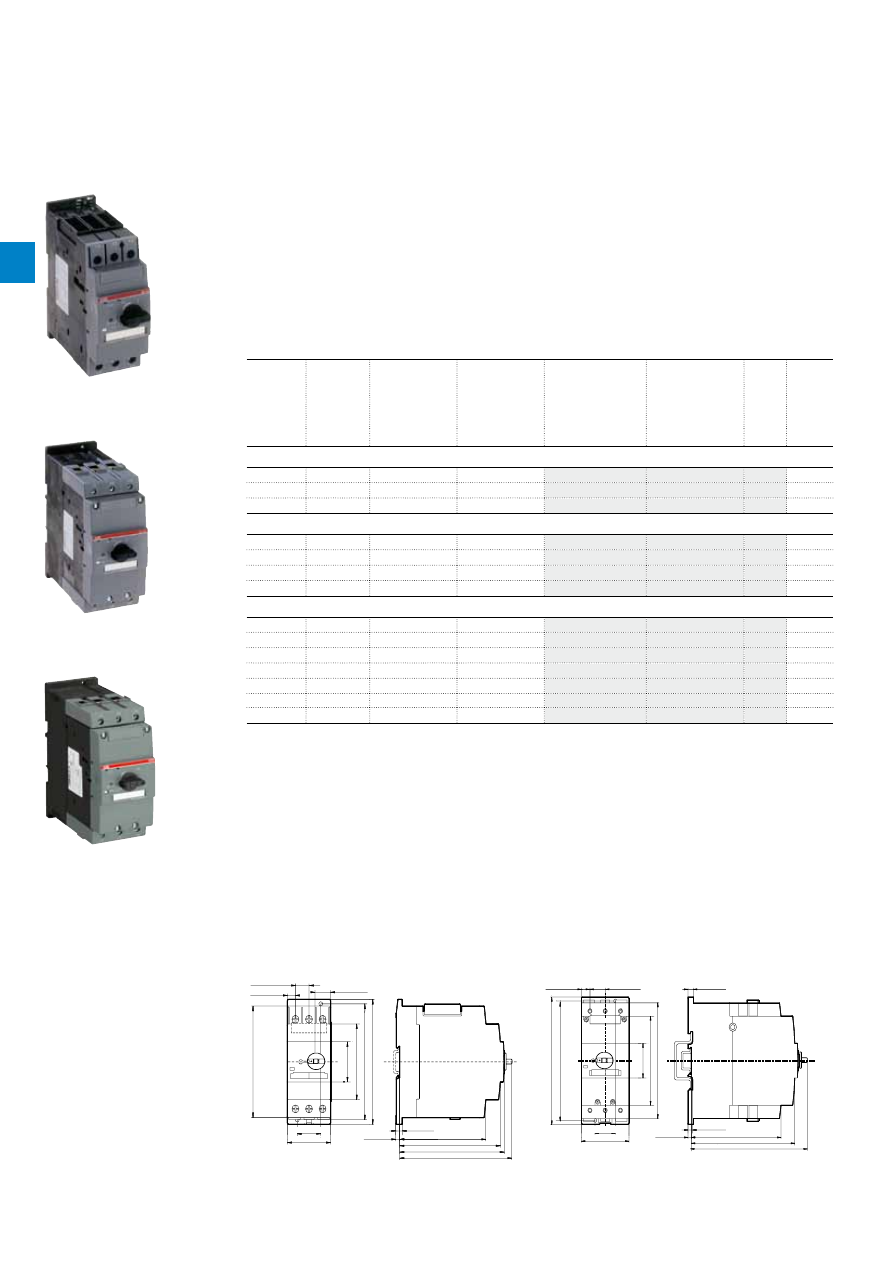

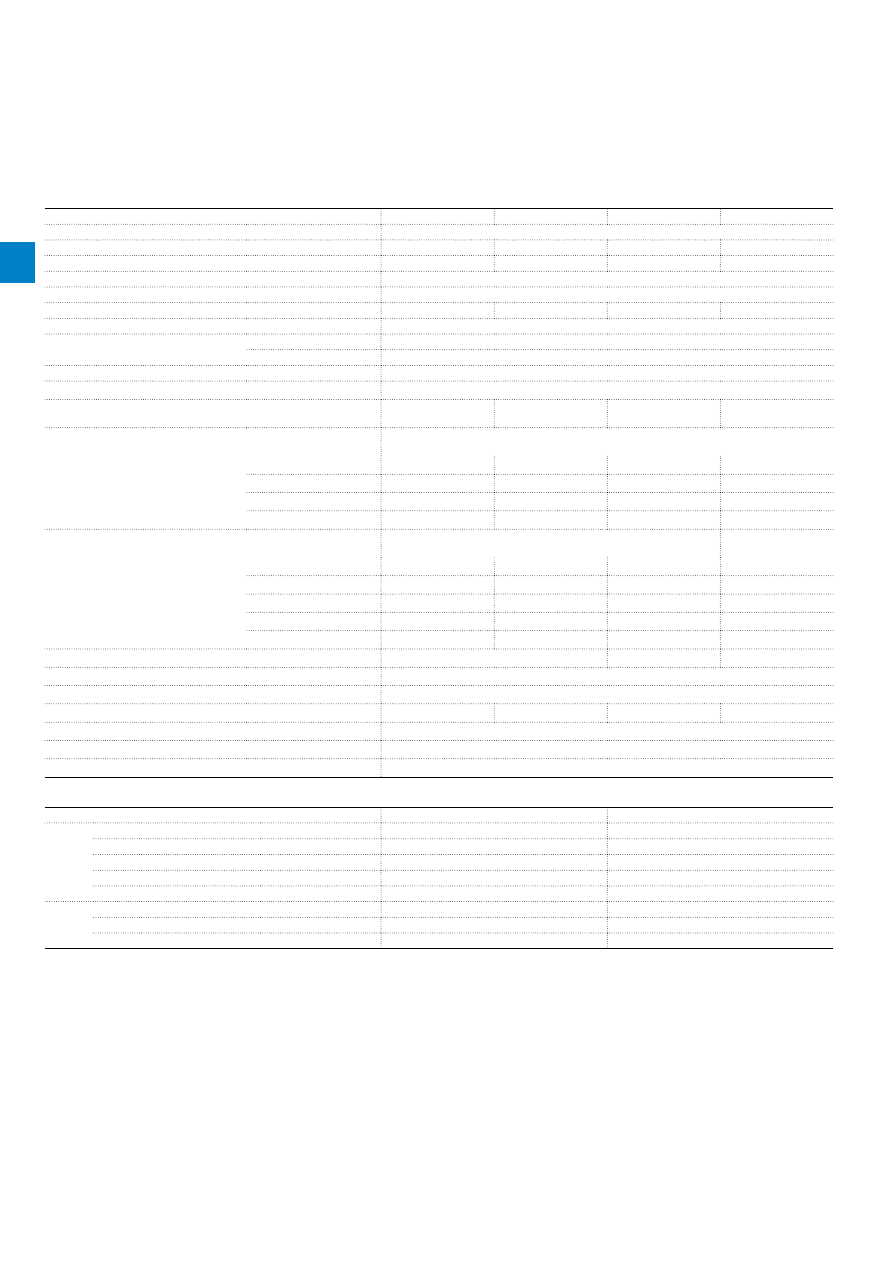

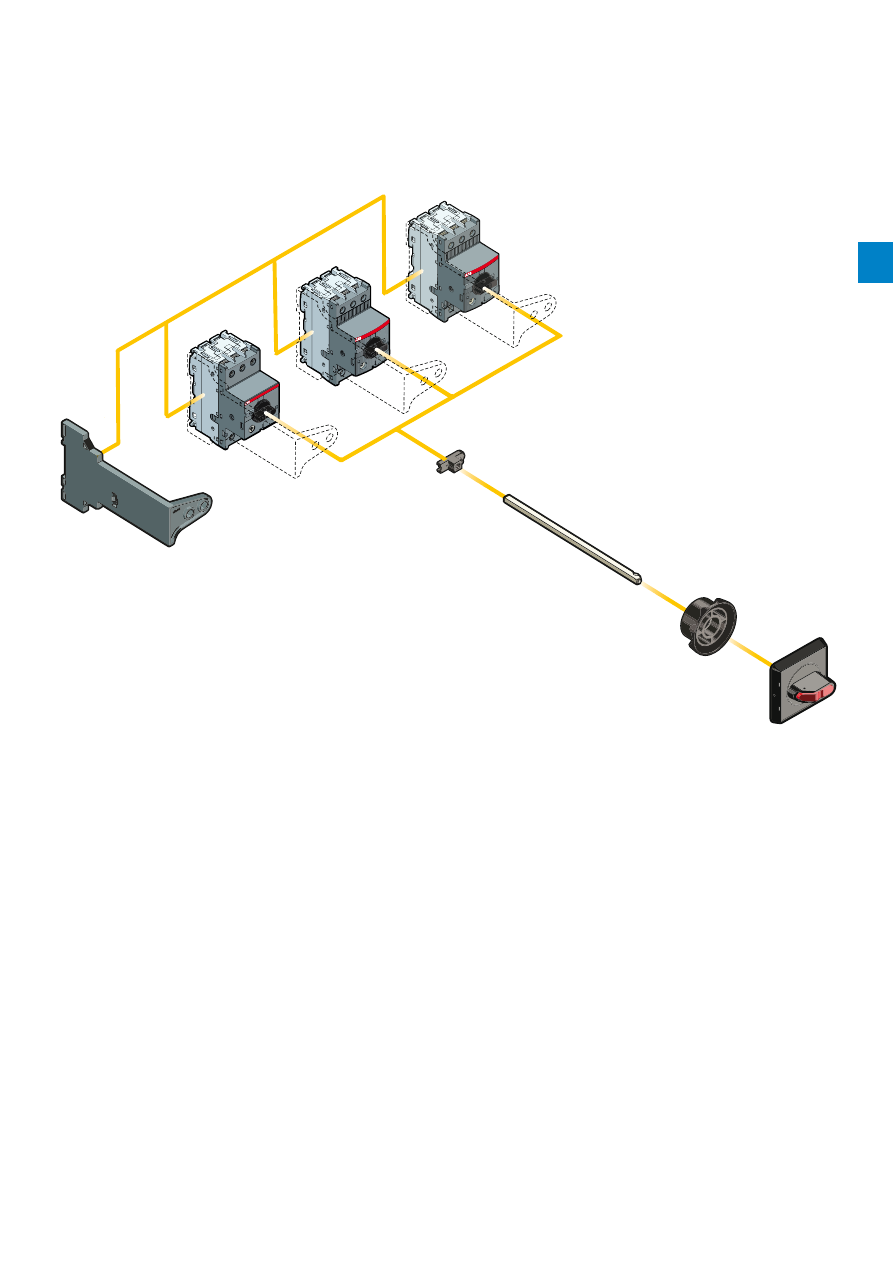

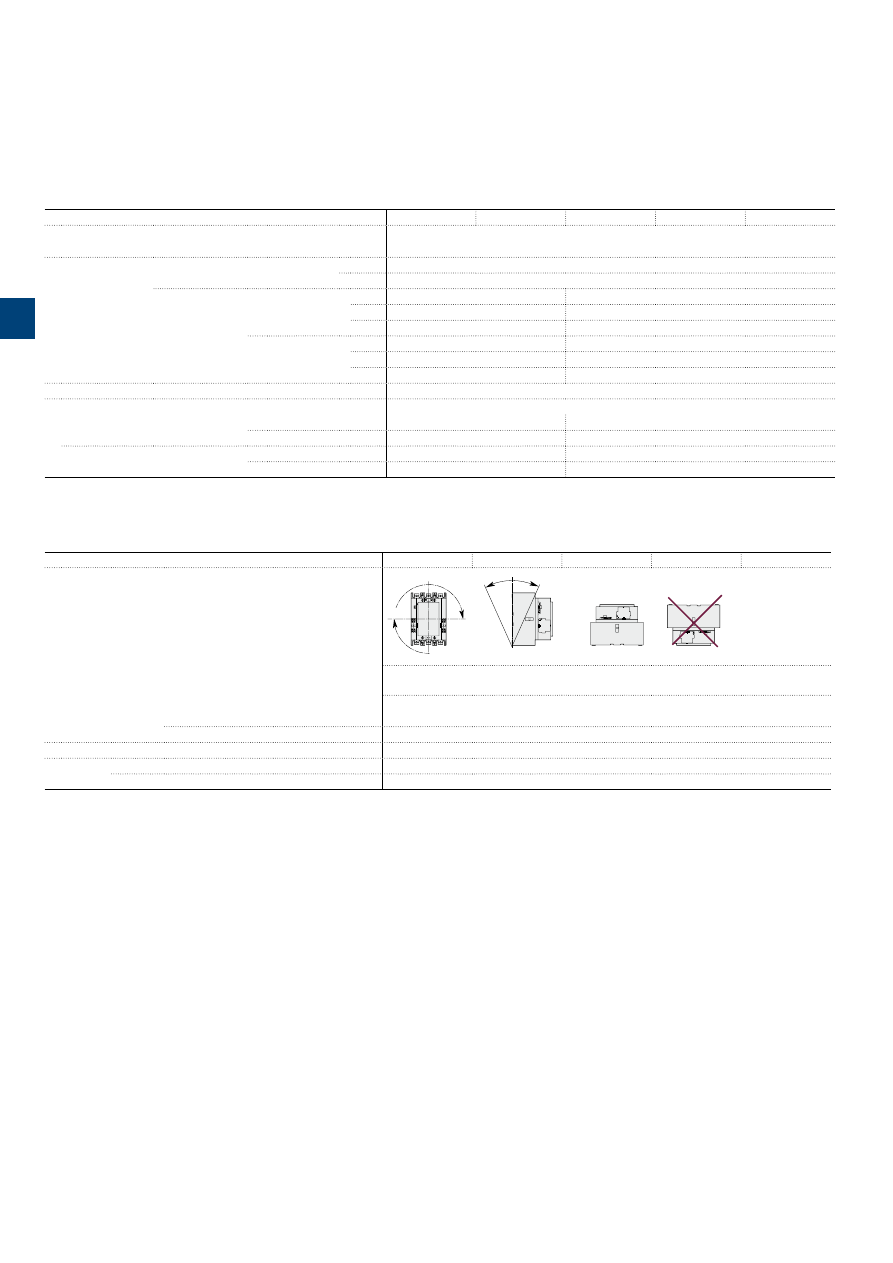

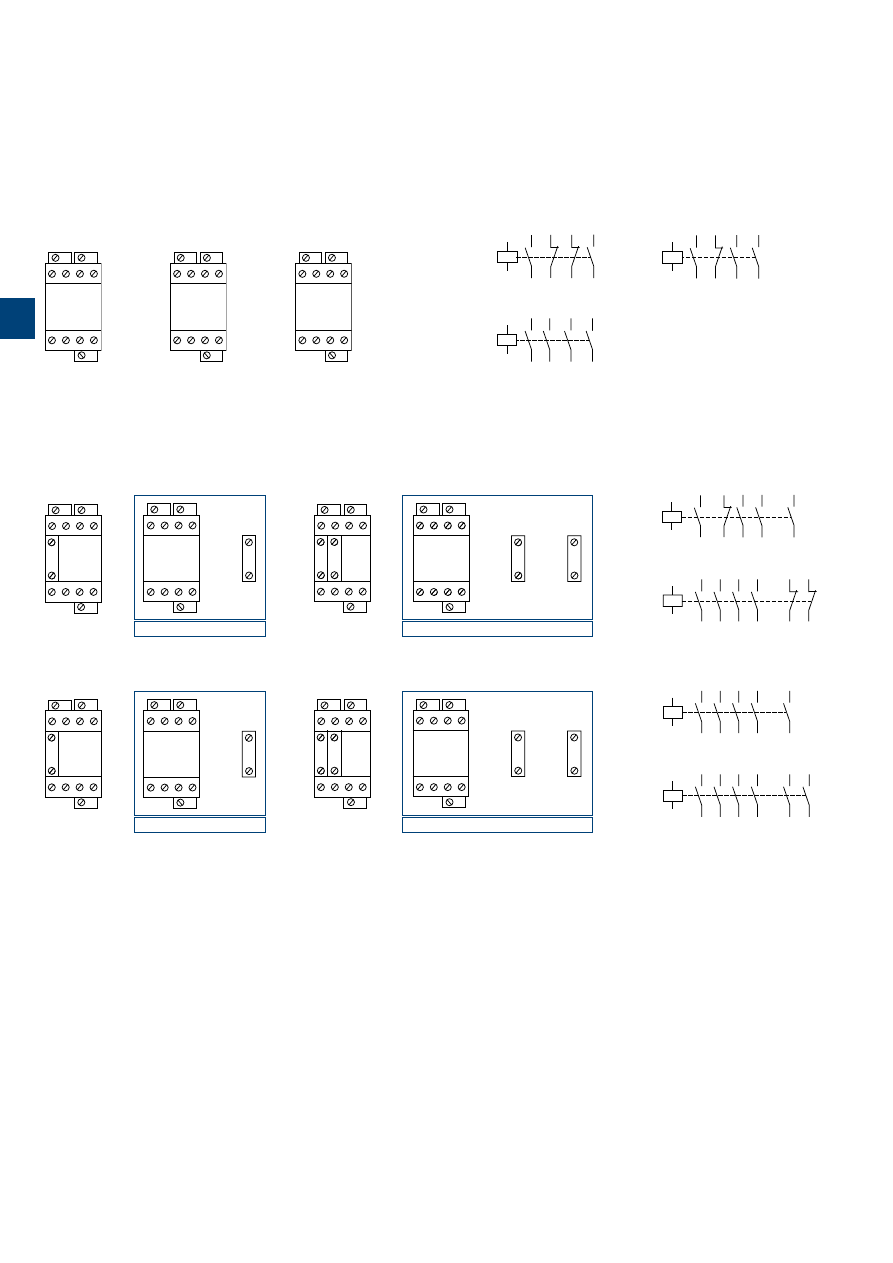

Manual motor starters

S

umma

ry

_2

2

ABB

|

2

/1

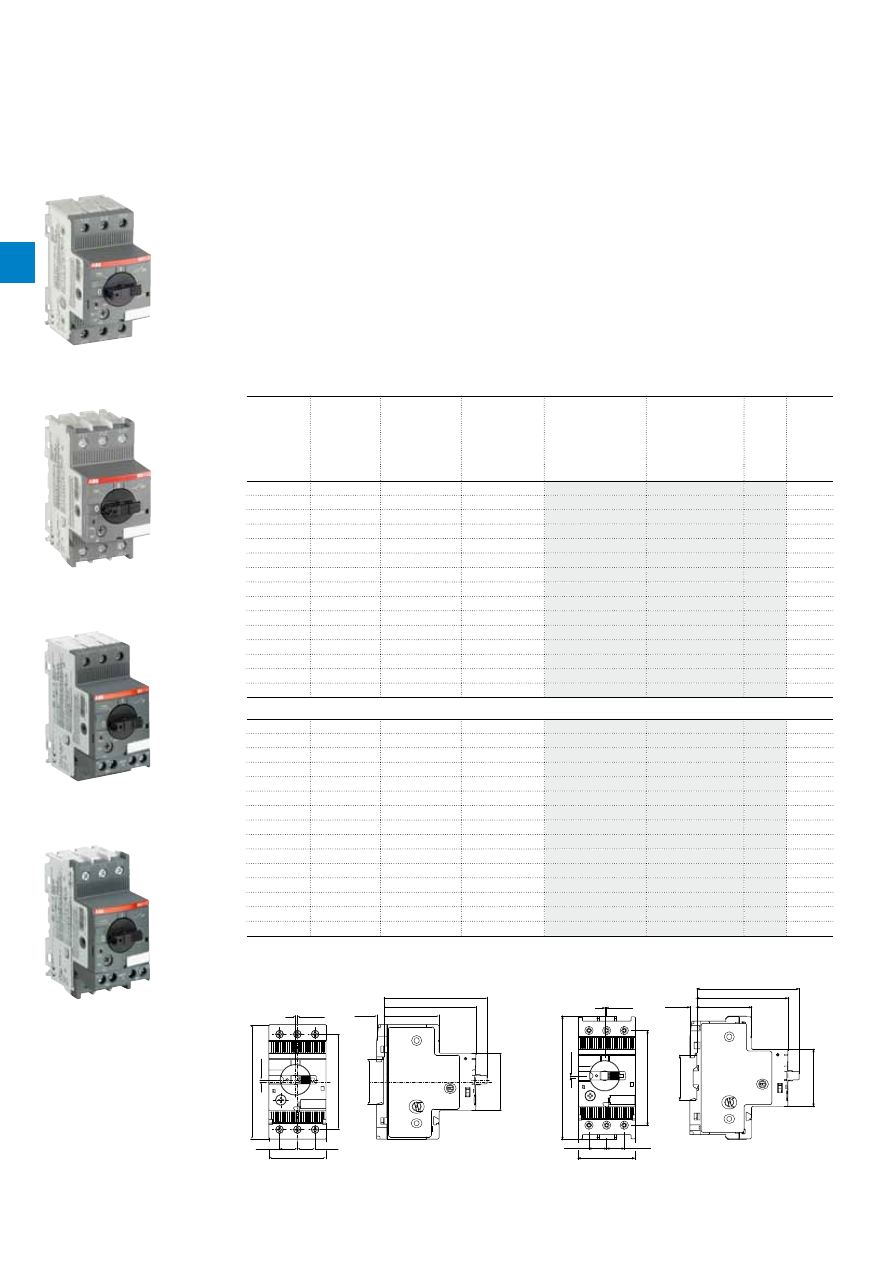

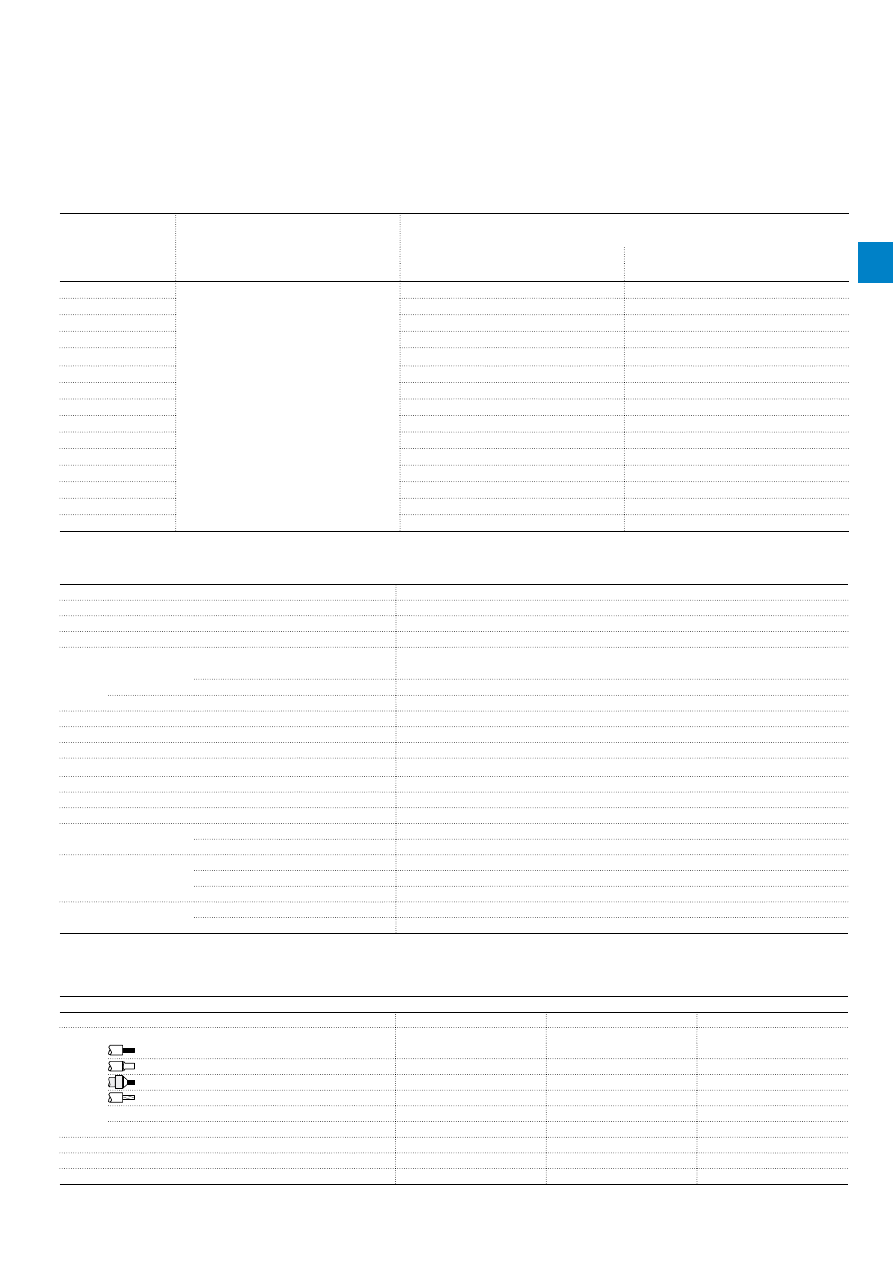

0.10 to 32 A – with thermal and electromagnetic protection

0.16 to 32 A – with electromagnetic protection

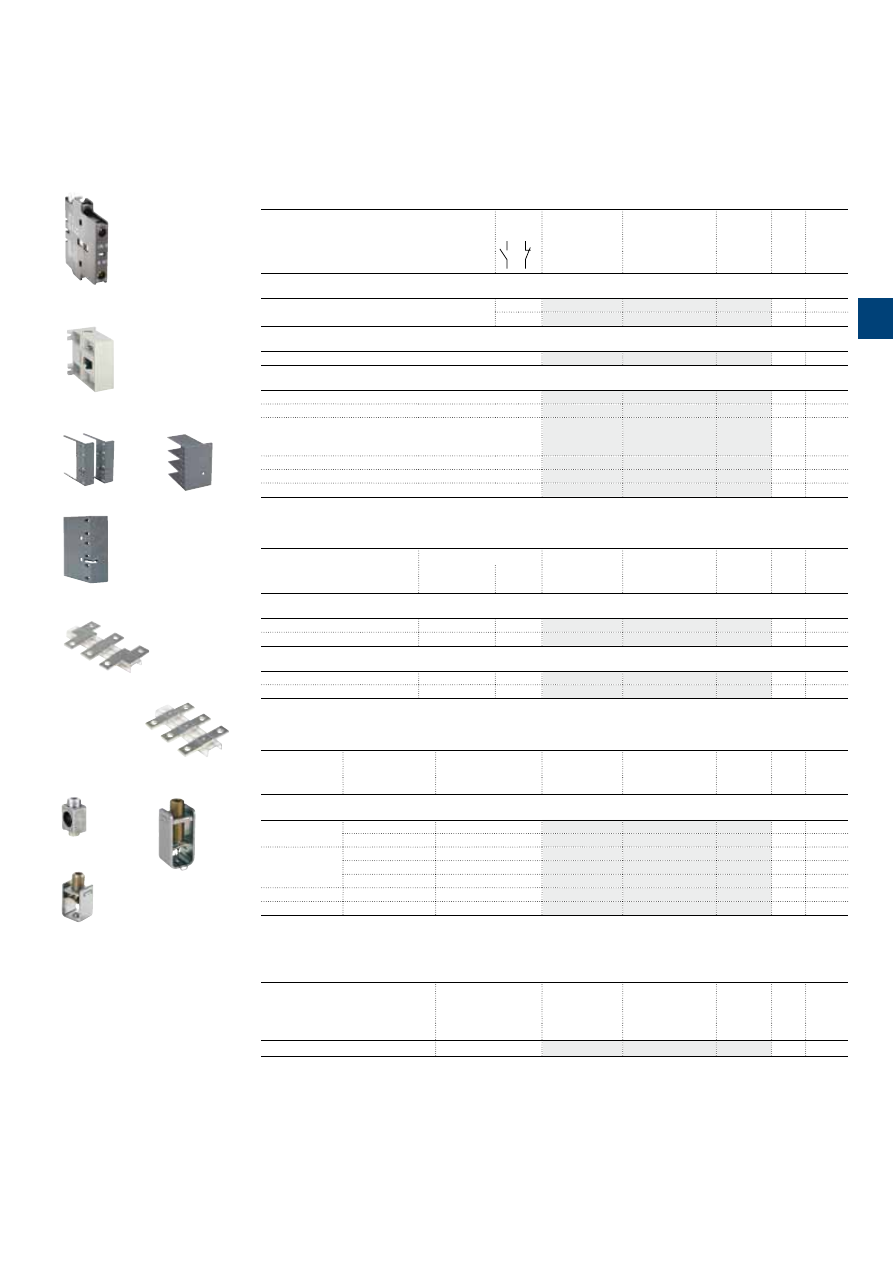

Main accessories for MS116, MS132, MO132

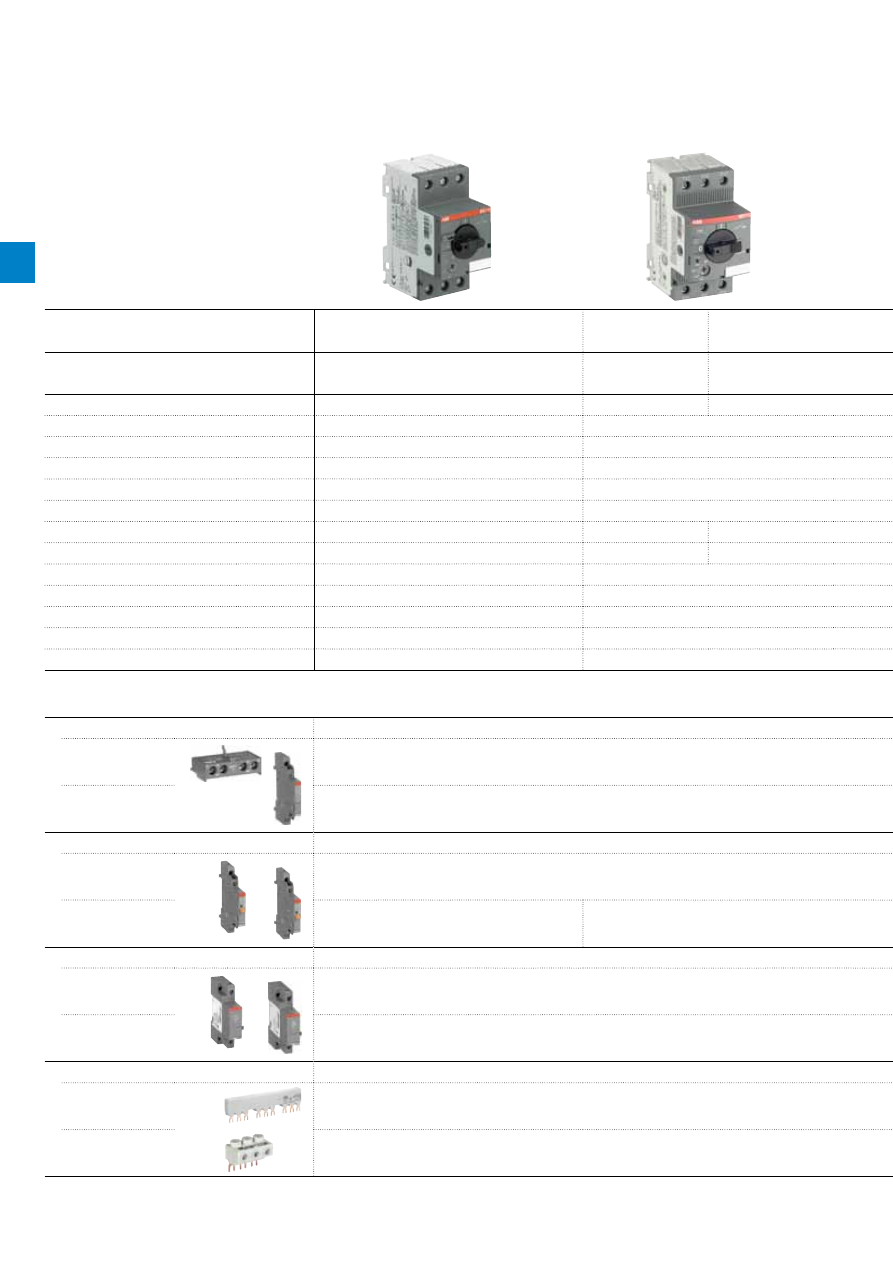

22 to 100 A – with thermal and electromagnetic protection

MS450, MS495, MS497 manual motor starters

32 to 100 A – with electromagnetic protection

MO450, MO495, MO496 manual motor starters

Main accessories for MS450, MS495, MS497, MO450,

MO495, MO496

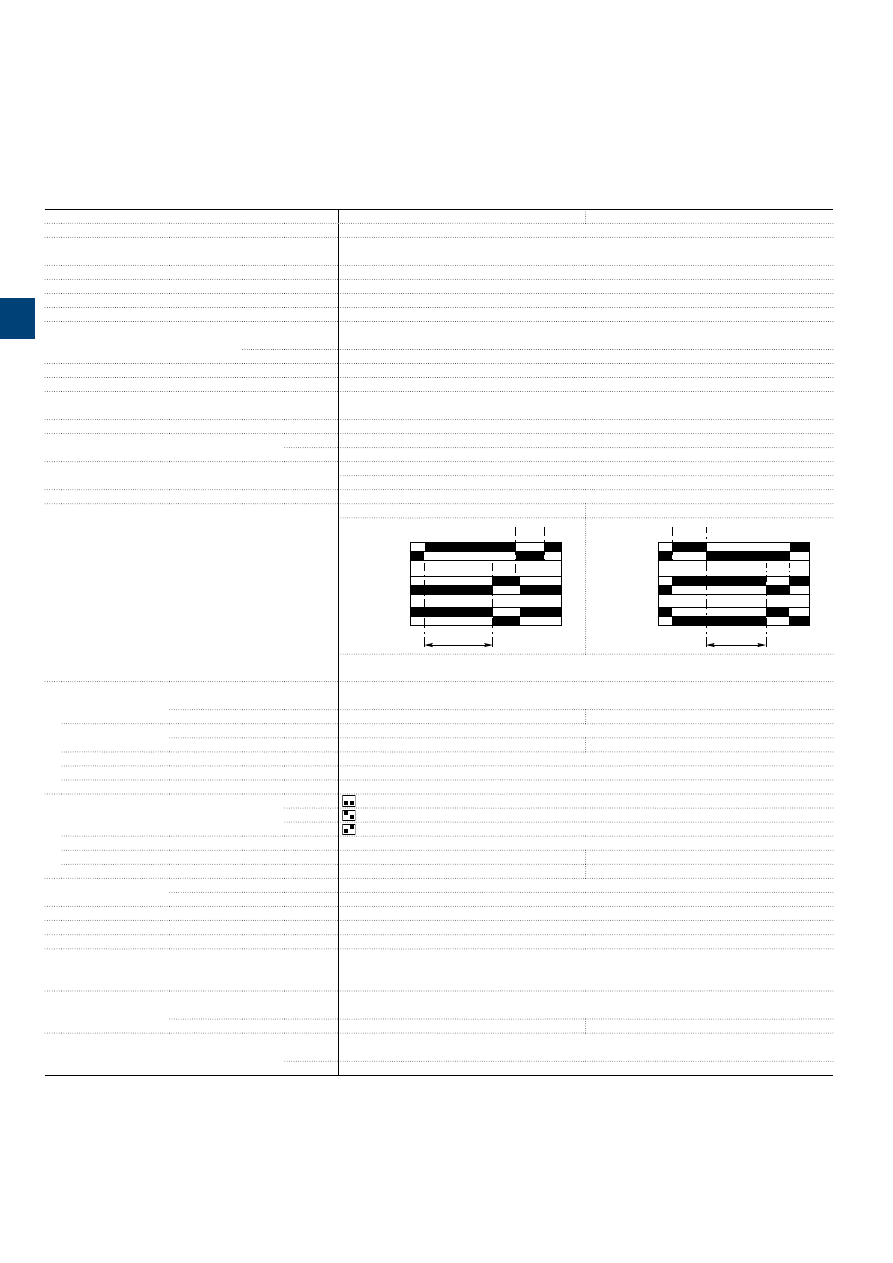

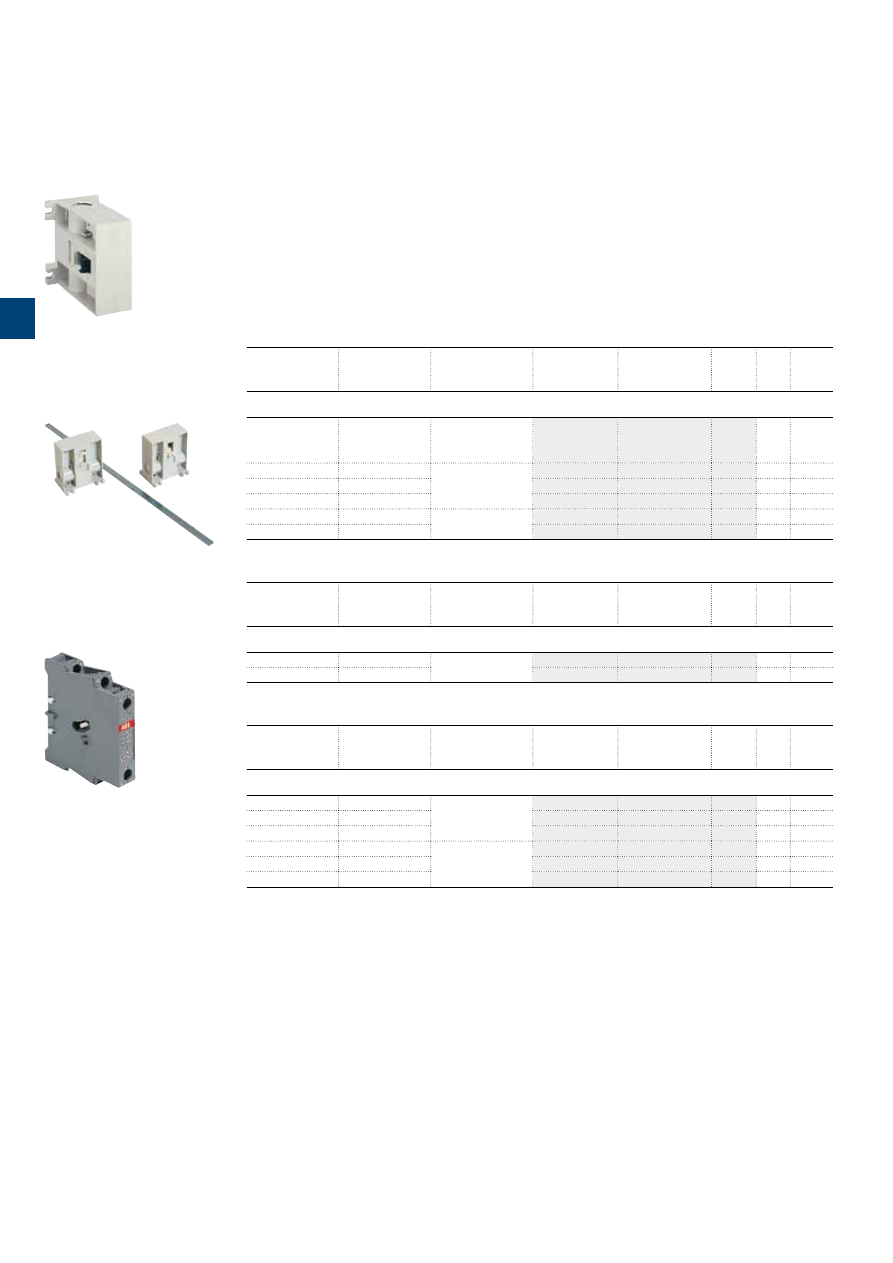

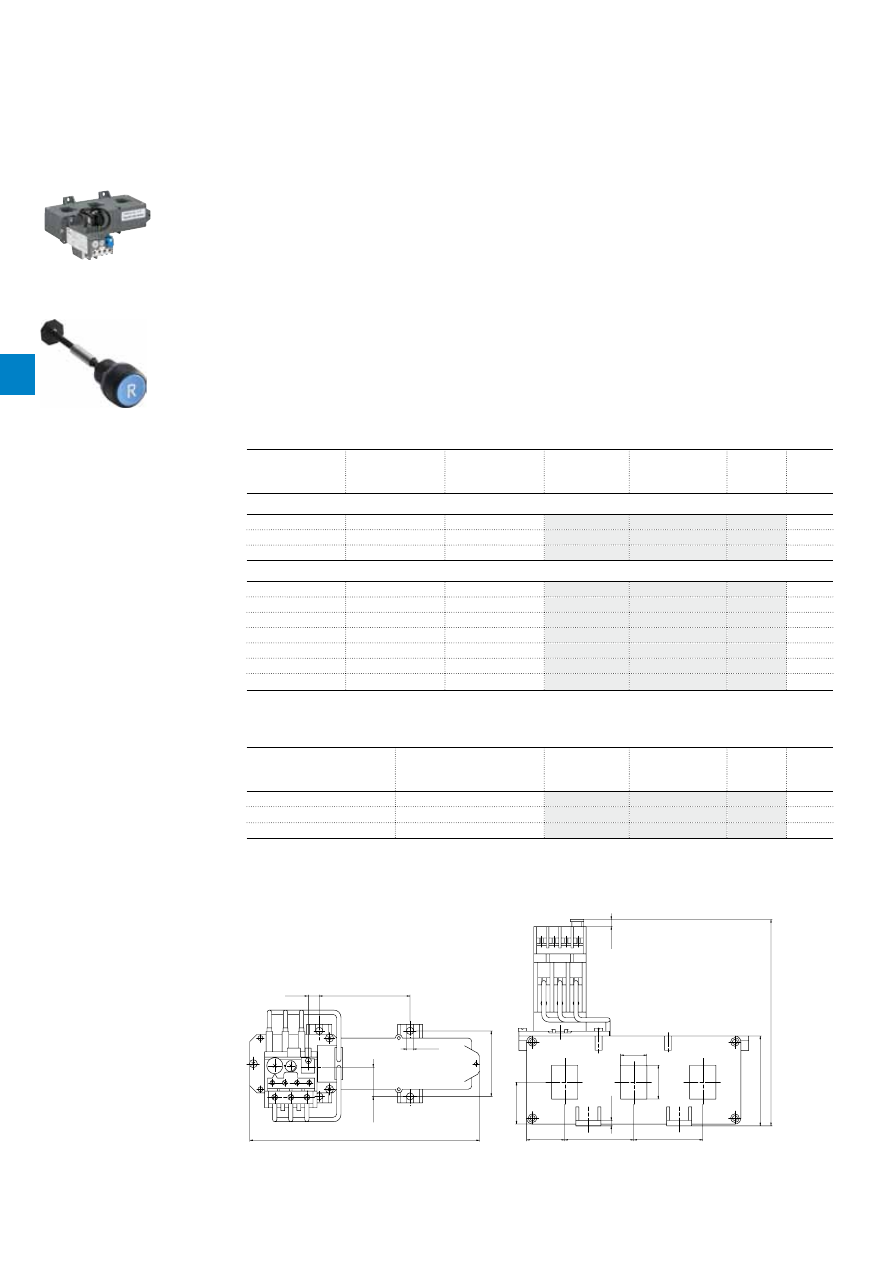

2CDC241010F0011

1SBC101232F0010

2CDC241004F0009

1SBC101184F0014

2CDC241020F0011

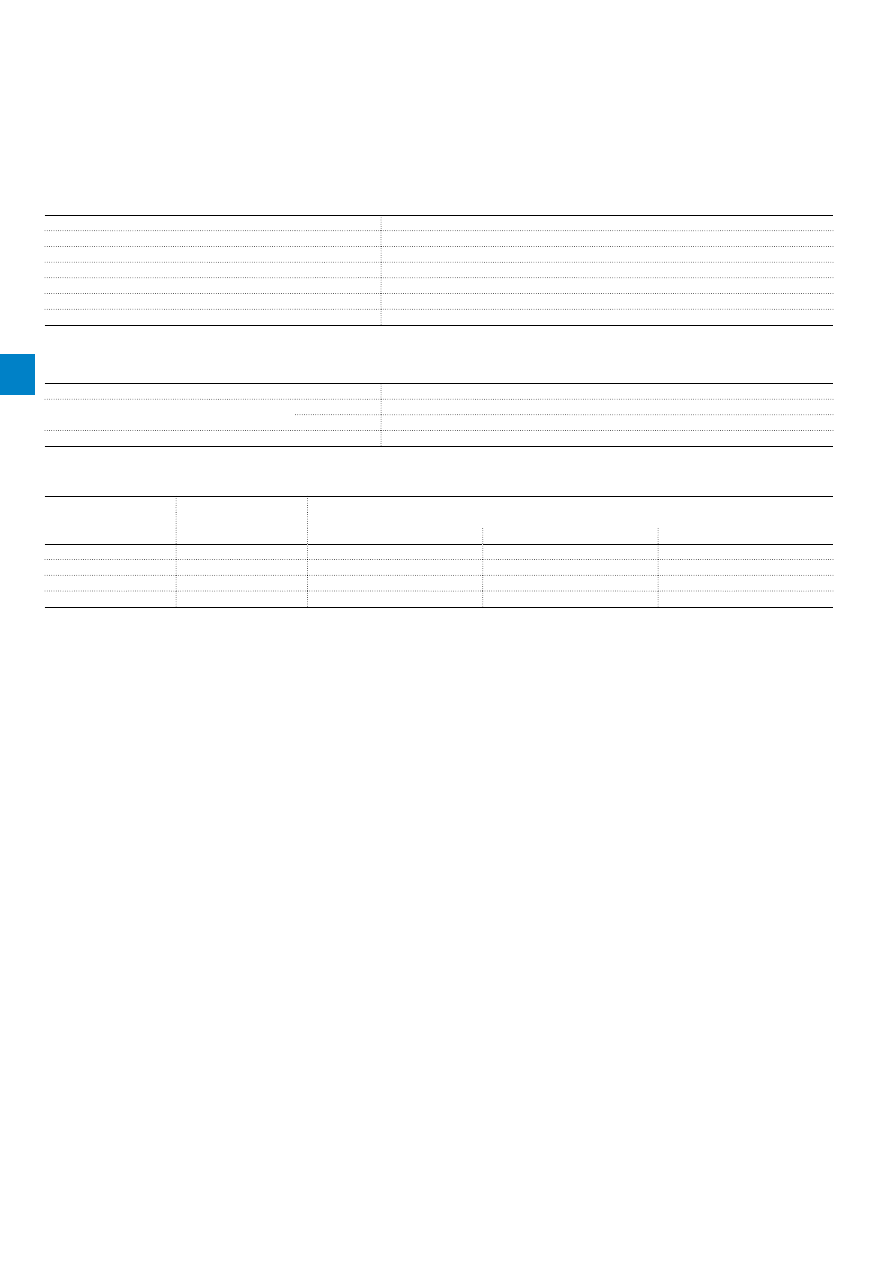

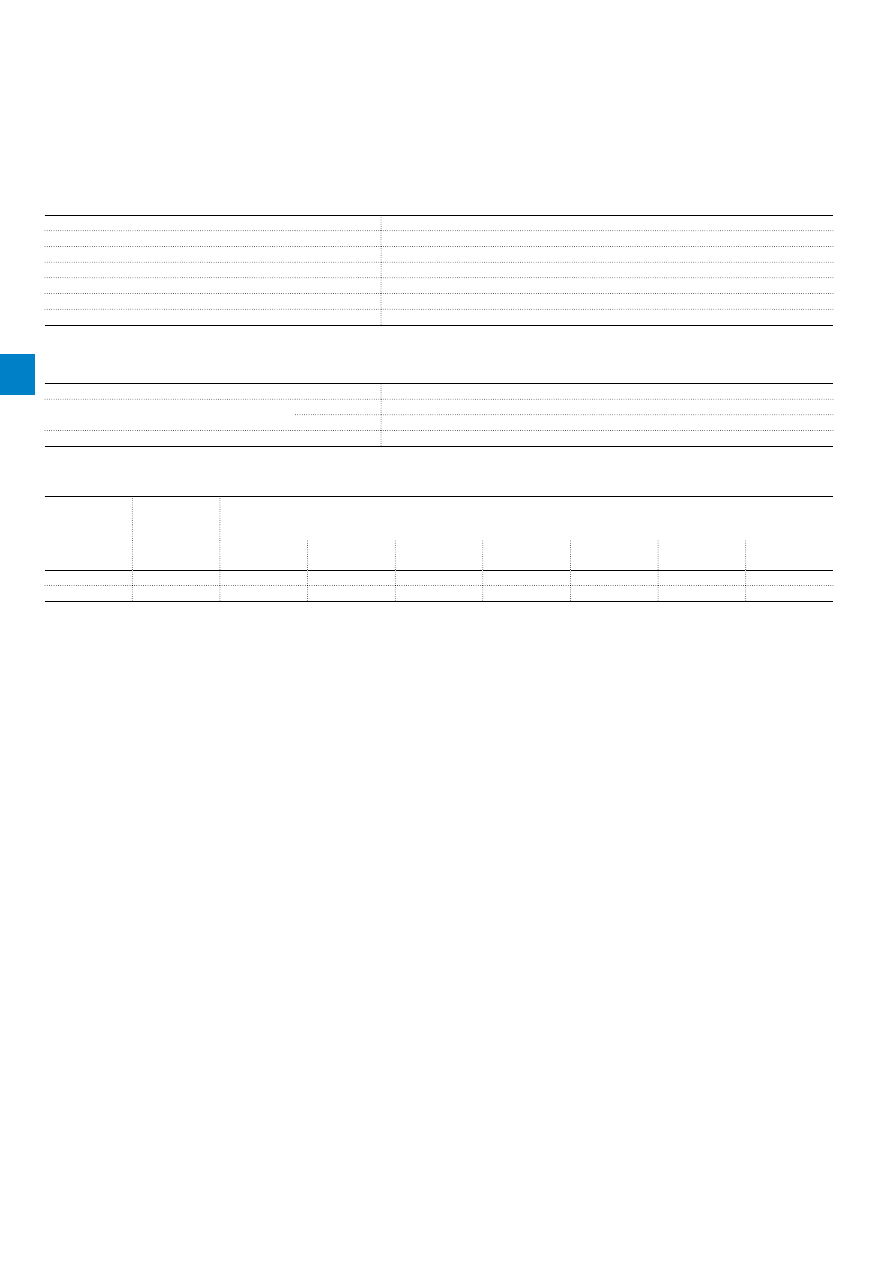

Thermal and electromagnetic

protection

Type MS116

MS132

MS450

MS495

MS497

Electromagnetic protection

Type -

MO132

MO450

MO495

MO496

Phase loss sensitivity

Yes

Yes

No

Yes

No

Yes

No

Yes

No

Switch position

ON/OFF

ON/OFF/TRIP

ON/OFF/TRIP

ON/OFF/TRIP

ON/OFF/TRIP

Magnetic trip indication

-

Yes

-

-

-

Lockable handle without accessories

-

Yes

Yes

Yes

Yes

Disconnecting feature

Yes

Yes

Yes

Yes

Yes

Width

45 mm

45 mm

55 mm

70 mm

70 mm

Rated operational current Ie

0.16...32 A

0.16....32 A

0.16....32 A

40...50 A

40...50 A

63...100 A

63...100 A

32...100 A

32...100 A

Setting range for thermal release

0.10...32 A

0.10....32 A

-

28...50 A

-

45...100 A

-

22...100 A

-

Rated operational voltage Ue

690 V AC

690 V AC / 250 V DC

690 V AC / 440 V DC

690 V AC / 440 V DC

690 V AC / 440 V DC

Rated frequency

50/60 Hz

DC, 50/60 Hz

DC, 50/60 Hz

DC, 50/60 Hz

DC, 50/60 Hz

Trip class

10A

10

10

10

10

Short-circuit breaking capacity Ics

400 V AC

Up to 50 kA

Up to 100 kA

Up to 50 kA

Up to 50 kA

Up to 100 kA

Ambient air temperature open compensated

-25...+55 °C

-25...+60 °C

-20...+60 °C

-20...+60 °C

-20...+60 °C

Main accessories

Auxiliary contacts

Front mounting

HKF1

HK4

Side mounting

HK1

HKS4

Signalling contacts

Tripped alarm

SK1

SK4

Short-circuit alarm

-

CK1

SK4

Auxiliary trip units

Shunt trip

AA1

AA4

Undervoltage release

UA1

UA4

Busbar systems

3-phase busbar

PS1

PS4

-

Feeder terminals

S1

S4

-

Manual motor starters

2

/2 |

ABB

2

2CDC241010F0011

1SBC101232F0010

2CDC241004F0009

1SBC101184F0014

2CDC241020F0011

Thermal and electromagnetic

protection

Type MS116

MS132

MS450

MS495

MS497

Electromagnetic protection

Type -

MO132

MO450

MO495

MO496

Phase loss sensitivity

Yes

Yes

No

Yes

No

Yes

No

Yes

No

Switch position

ON/OFF

ON/OFF/TRIP

ON/OFF/TRIP

ON/OFF/TRIP

ON/OFF/TRIP

Magnetic trip indication

-

Yes

-

-

-

Lockable handle without accessories

-

Yes

Yes

Yes

Yes

Disconnecting feature

Yes

Yes

Yes

Yes

Yes

Width

45 mm

45 mm

55 mm

70 mm

70 mm

Rated operational current Ie

0.16...32 A

0.16....32 A

0.16....32 A

40...50 A

40...50 A

63...100 A

63...100 A

32...100 A

32...100 A

Setting range for thermal release

0.10...32 A

0.10....32 A

-

28...50 A

-

45...100 A

-

22...100 A

-

Rated operational voltage Ue

690 V AC

690 V AC / 250 V DC

690 V AC / 440 V DC

690 V AC / 440 V DC

690 V AC / 440 V DC

Rated frequency

50/60 Hz

DC, 50/60 Hz

DC, 50/60 Hz

DC, 50/60 Hz

DC, 50/60 Hz

Trip class

10A

10

10

10

10

Short-circuit breaking capacity Ics

400 V AC

Up to 50 kA

Up to 100 kA

Up to 50 kA

Up to 50 kA

Up to 100 kA

Ambient air temperature open compensated

-25...+55 °C

-25...+60 °C

-20...+60 °C

-20...+60 °C

-20...+60 °C

Main accessories

Auxiliary contacts

Front mounting

HKF1

HK4

Side mounting

HK1

HKS4

Signalling contacts

Tripped alarm

SK1

SK4

Short-circuit alarm

-

CK1

SK4

Auxiliary trip units

Shunt trip

AA1

AA4

Undervoltage release

UA1

UA4

Busbar systems

3-phase busbar

PS1

PS4

-

Feeder terminals

S1

S4

-

ABB

|

2

/3

2C

D

C

13

10

4

6

C

0

2

01

2

2C

D

C

13

10

3

9

C

0

2

01

2

/4 |

ABB

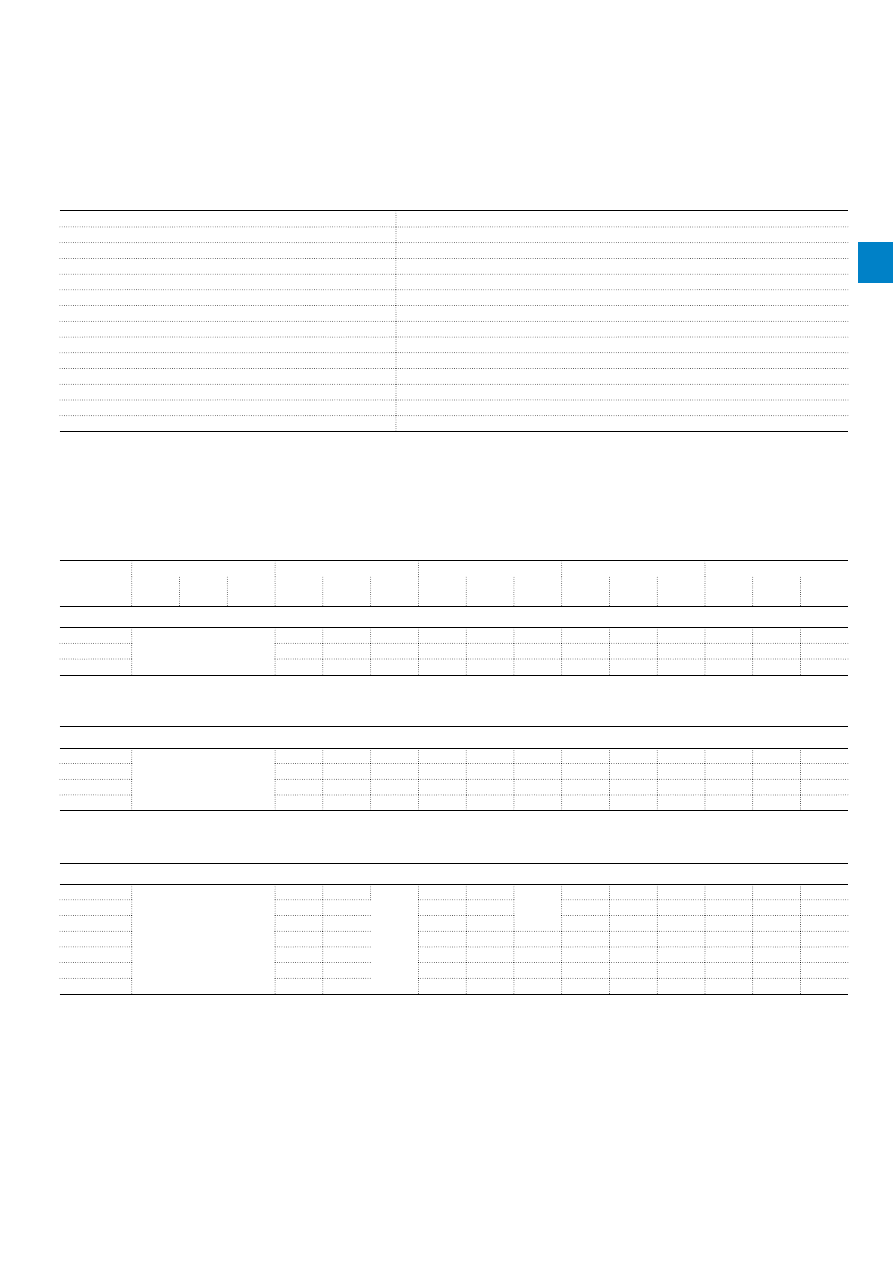

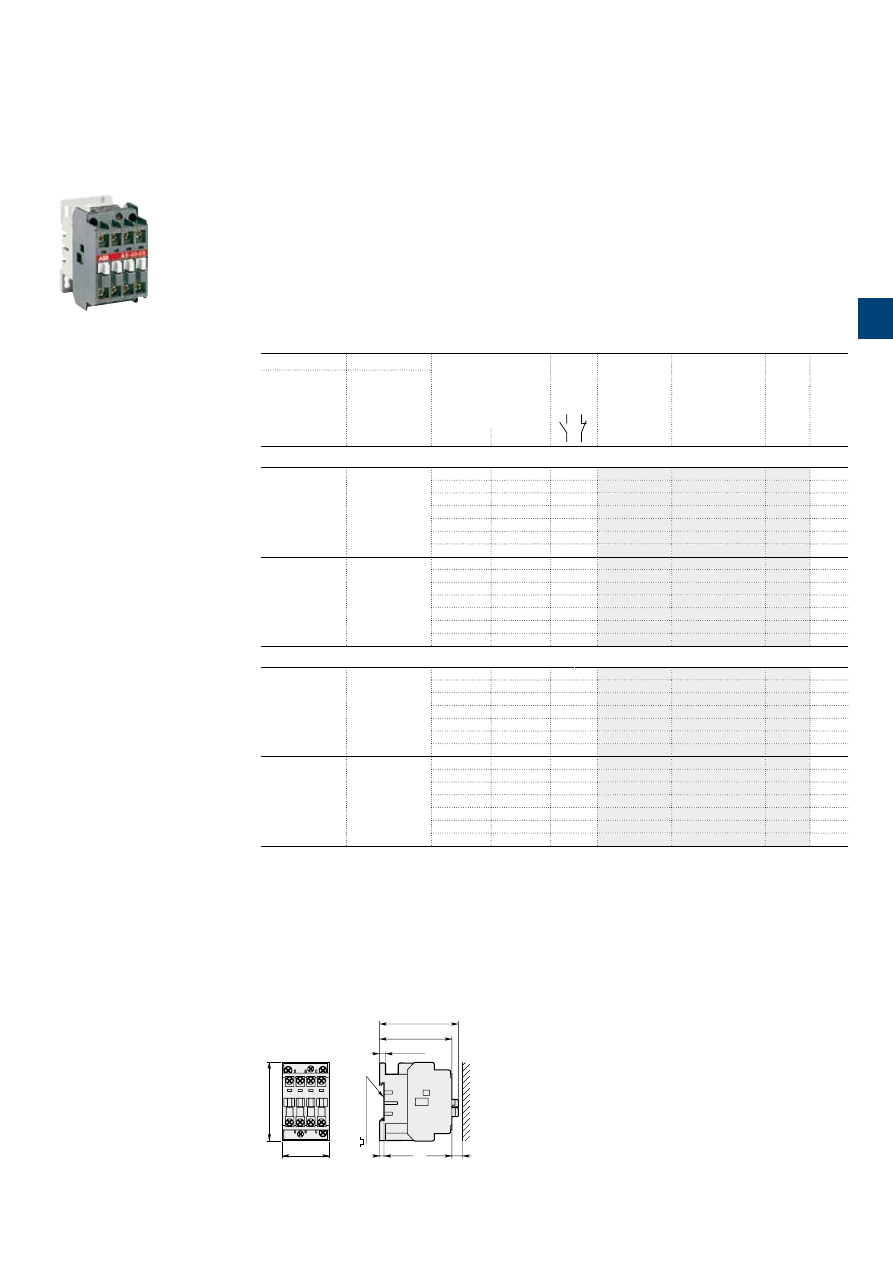

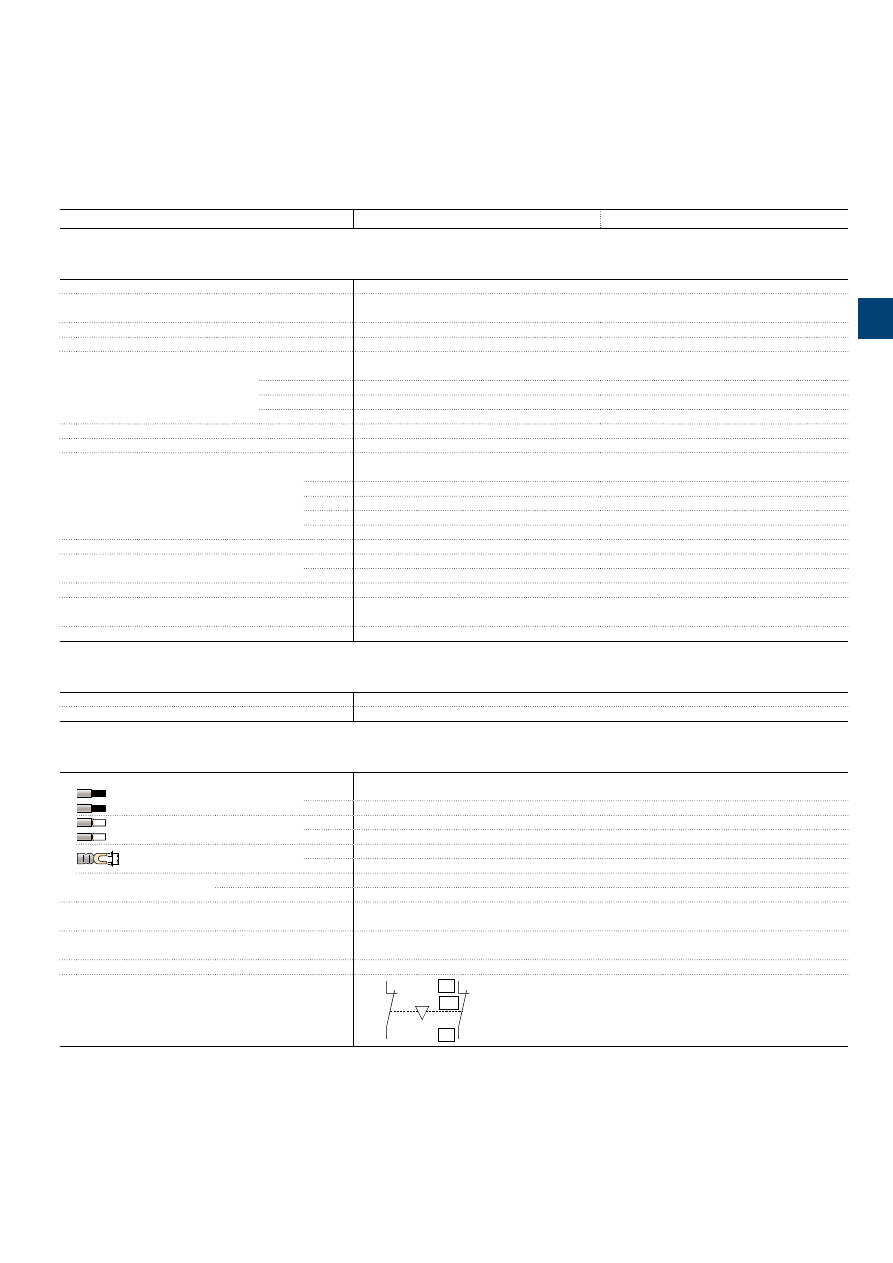

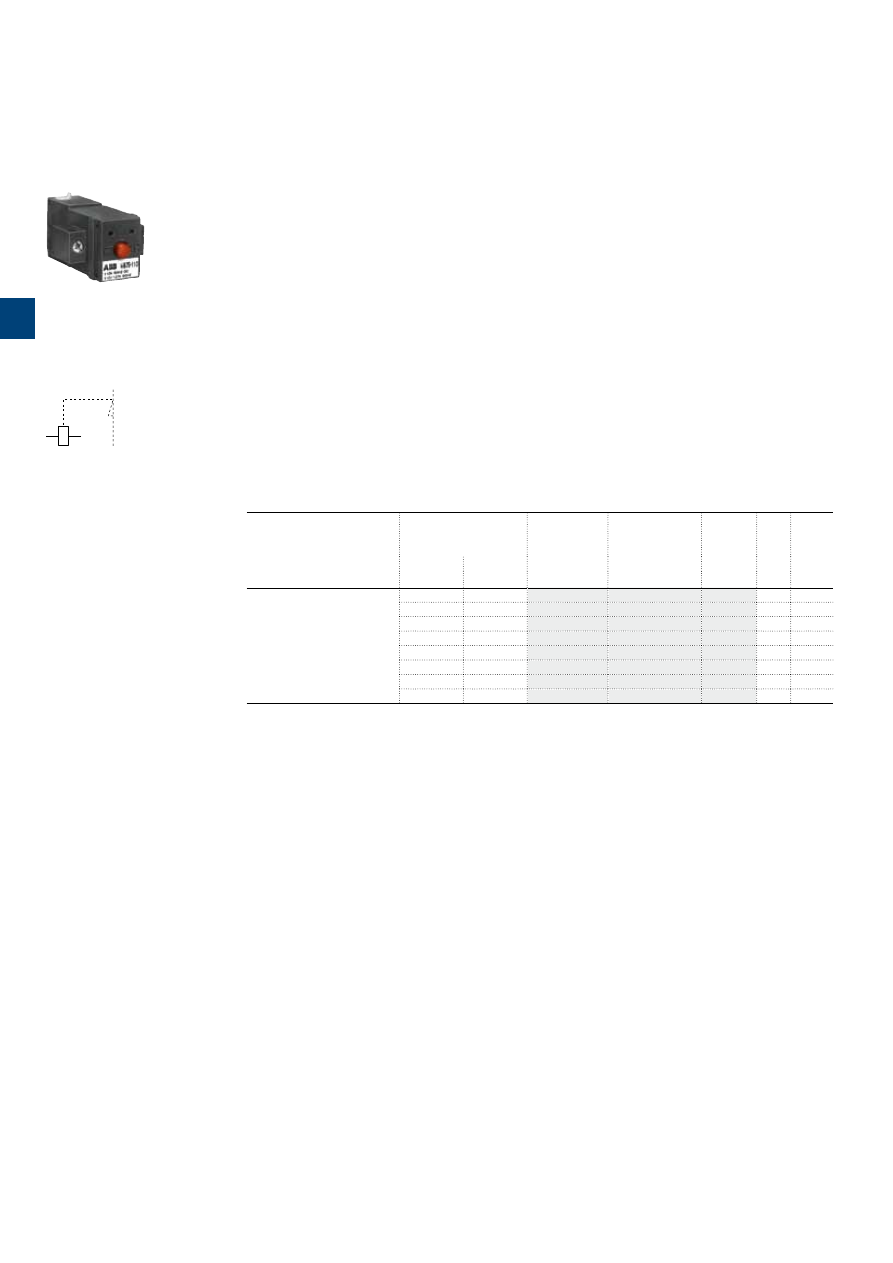

MS116 manual motor starters

0.10 to 32 A – with thermal and electromagnetic protection

Description

Manual motor starters (MMS) are protection devices for the main circuit. They combine motor control and

protection in a single device. MMS are used mainly to switch motors manually ON/OFF and protect them

and the installation fuse less against short-circuit, overload and phase failures. Fuse less protection with

a manual motor starter saves costs, space and ensures a quick reaction under short-circuit condition, by

switching off the motor within milliseconds.

MS116 is a compact and economic range for motor protection up to 15.5 kW (400 V) / 32 A in width of 45 mm.

Further features are the build-in disconnect function, temperature compensation, trip-free mechanism and

a rotary handle with a clear switch position indication. The manual motor starter is suitable for three- and

single-phase applications. Auxiliary contacts, signalling contacts, undervoltage releases, shunt trips, three-

phase bus bars, power in-feed blocks and locking devices for protection against unauthorized changes

are available as accessory.

Ordering details

Rated

operational

power

400 V

AC-3

Setting range Short-circuit

breaking

capacity Ics at

400 V AC

Rated

instantaneous

short-circuit

current setting li

Type

Order code

Weight

(1 pce)

kW

A

kA

A

kg

0.03

0.10...0.16

50

1.56

MS116-0.16

0.225

0.06

0.16...0.25

50

2.44

MS116-0.25

0.225

0.09

0.25...0.40

50

3.90

MS116-0.4

0.225

0.12

0.40...0.63

50

6.14

MS116-0.63

0.225

0.25

0.63...1.00

50

11.50

MS116-1.0

0.225

0.55

1.00...1.60

50

18.40

MS116-1.6

0.265

0.75

1.60...2.50

50

28.75

MS116-2.5

0.265

1.5

2.50...4.00

50

50.00

MS116-4.0

0.265

2.2

4.00...6.30

50

78.75

MS116-6.3

0.265

4.0

6.30...10.0

50

150

MS116-10

0.265

5.5

8.00...12.0

25

180

MS116-12

0.265

7.5

10.0...16.0

16

240

MS116-16

0.265

9.0

16.0...20.0

10

300

MS116-20

0.310

12.5

20.0...25.0

10

375

MS116-25

0.310

15.5

25.0...32.0

10

480

MS116-32

0.310

Auxiliary contacts mounted on the front (1 N.O. + 1 N.C.)

0.03

0.10...0.16

50

1.56

MS116-0.16-HKF1-11 1SAM250005R1001

0.240

0.06

0.16...0.25

50

2.44

MS116-0.25-HKF1-11 1SAM250005R1002

0.240

0.09

0.25...0.40

50

3.90

MS116-0.4-HKF1-11

0.240

0.12

0.40...0.63

50

6.14

MS116-0.63-HKF1-11 1SAM250005R1004

0.240

0.25

0.63...1.00

50

11.50

MS116-1.0-HKF1-11

0.240

0.55

1.00...1.60

50

18.40

MS116-1.6-HKF1-11

0.280

0.75

1.60...2.50

50

28.75

MS116-2.5-HKF1-11

0.280

1.5

2.50...4.00

50

50.00

MS116-4.0-HKF1-11

0.280

2.2

4.00...6.30

50

78.75

MS116-6.3-HKF1-11

0.280

4.0

6.30...10.0

50

150

MS116-10.0-HKF1-11 1SAM250005R1010

0.280

5.5

8.00...12.0

25

180

MS116-12.0-HKF1-11 1SAM250005R1012

0.280

7.5

10.0...16.0

16

240

MS116-16.0-HKF1-11 1SAM250005R1011

0.280

9.0

16.0...20.0

10

300

MS116-20-HKF1-11

0.326

12.5

20.0...25.0

10

375

MS116-25-HKF1-11

0.326

15.5

25.0...32.0

10

480

MS116-32-HKF1-11

0.326

2CDC241010F0011

MS116-16

2CDC241001F0011

MS116-25

2CDC241013F0011

MS116-0.16-HKF1-11

2CDC241012F0011

MS116-32-HKF1-11

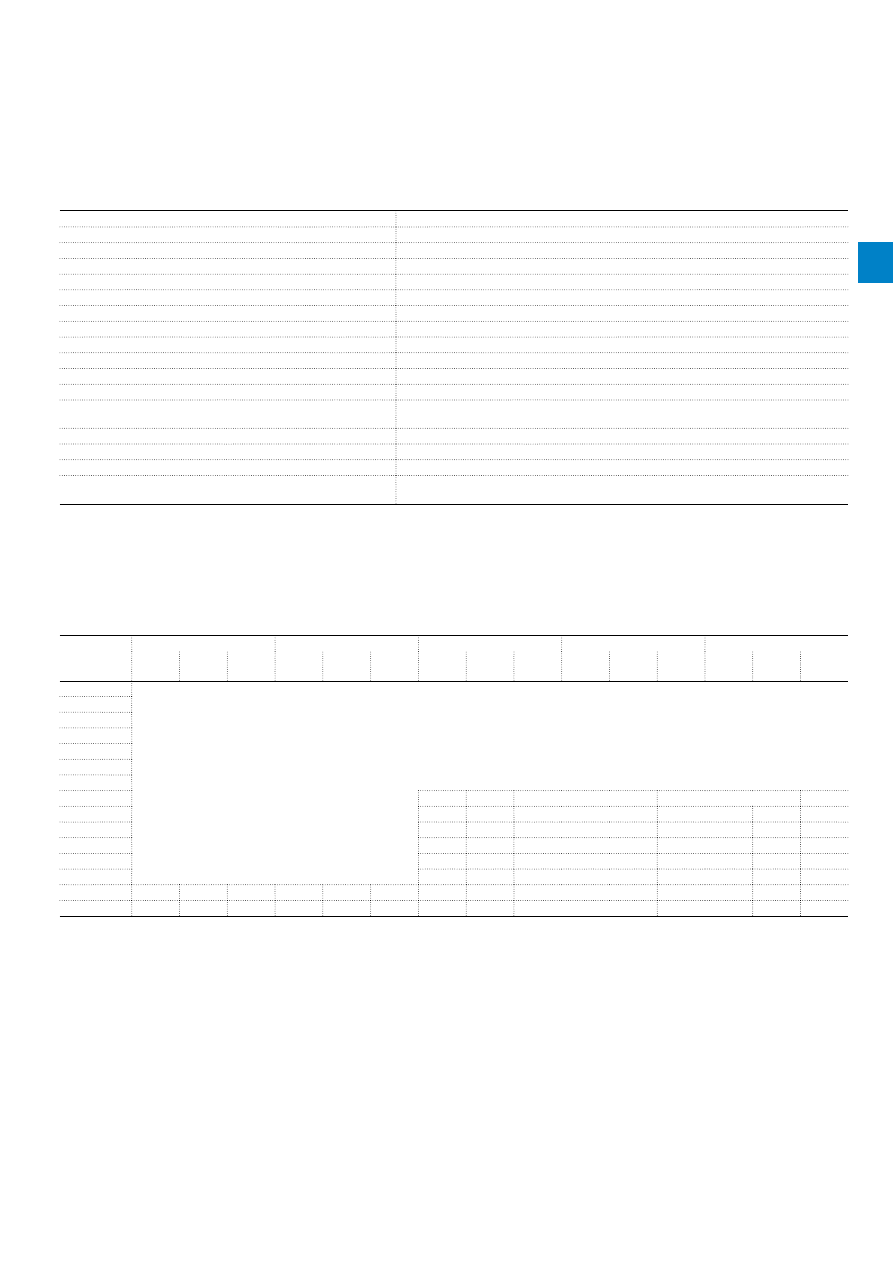

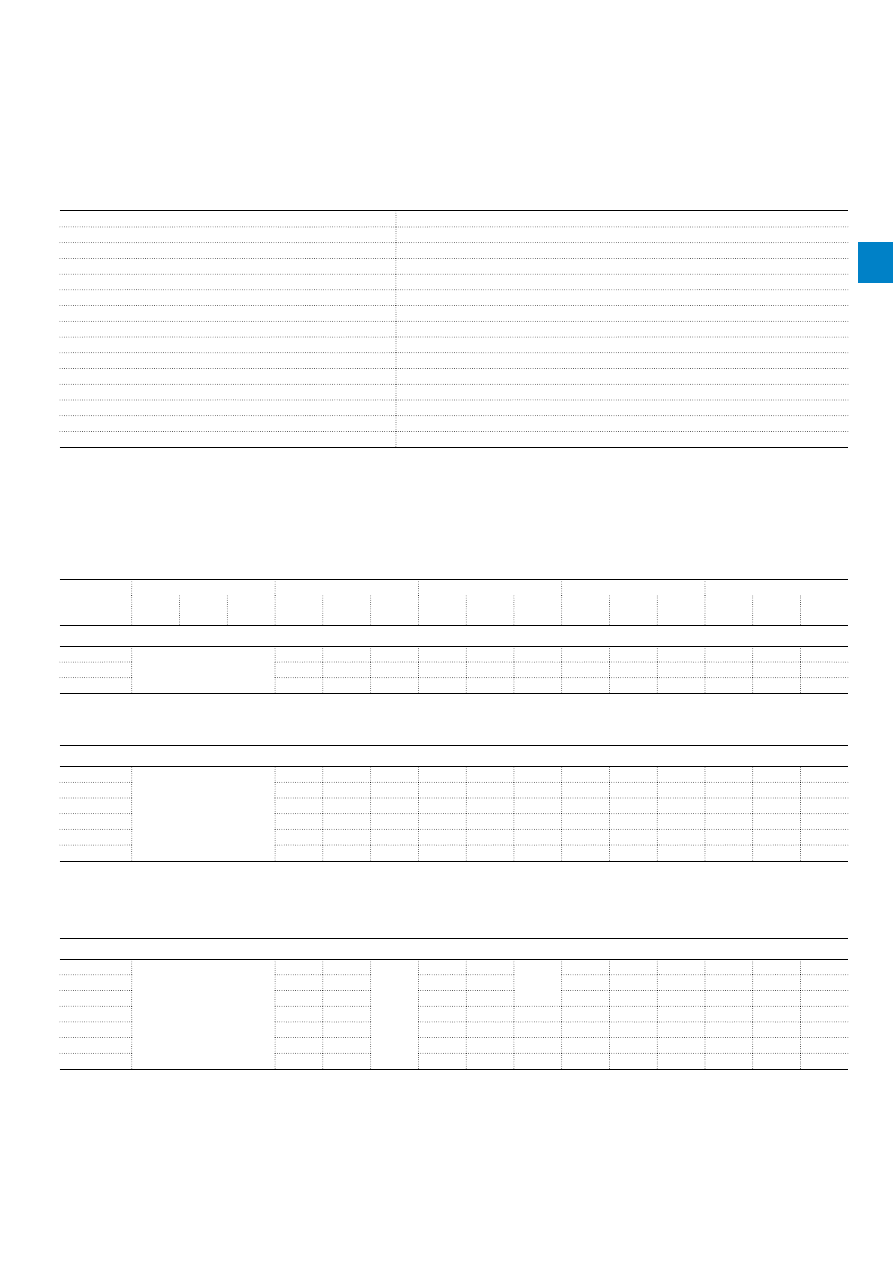

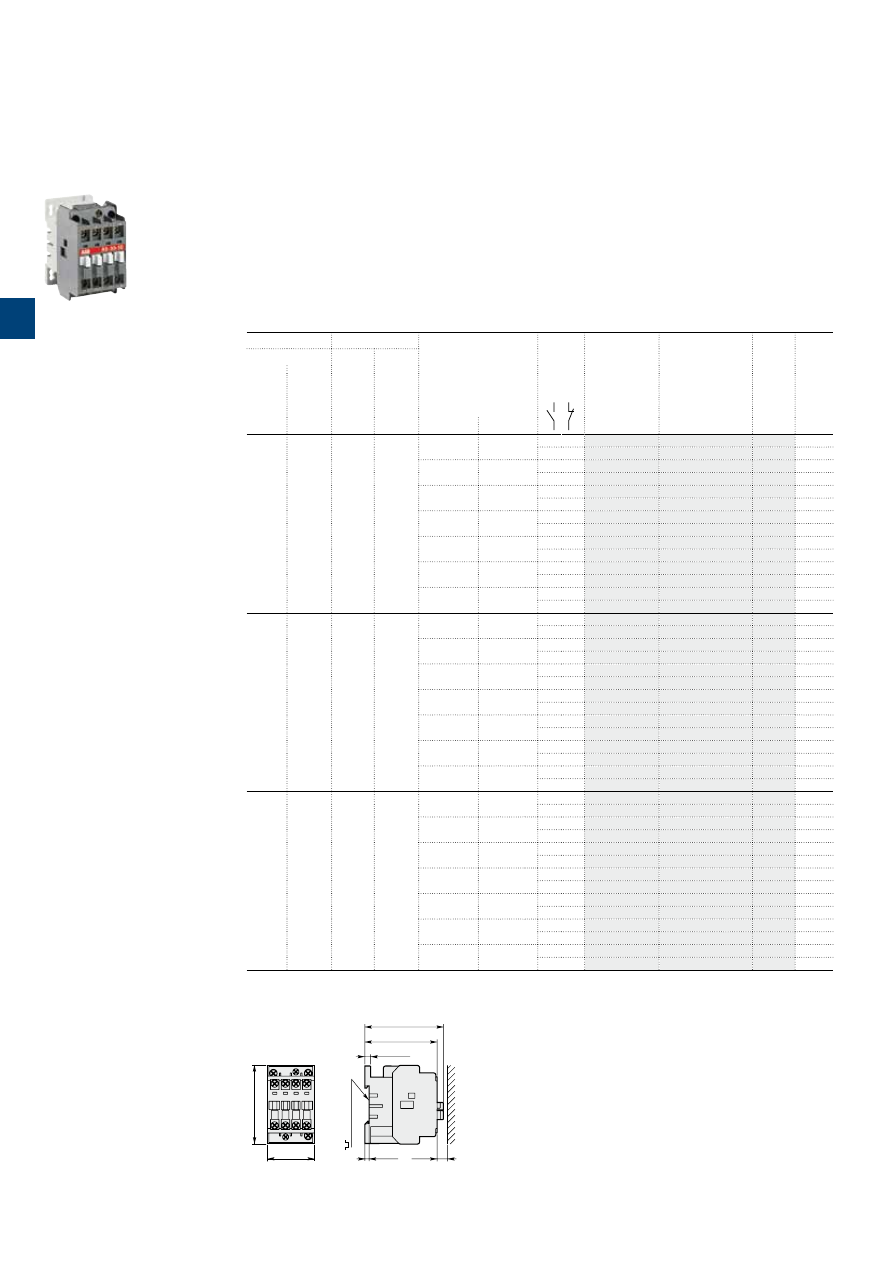

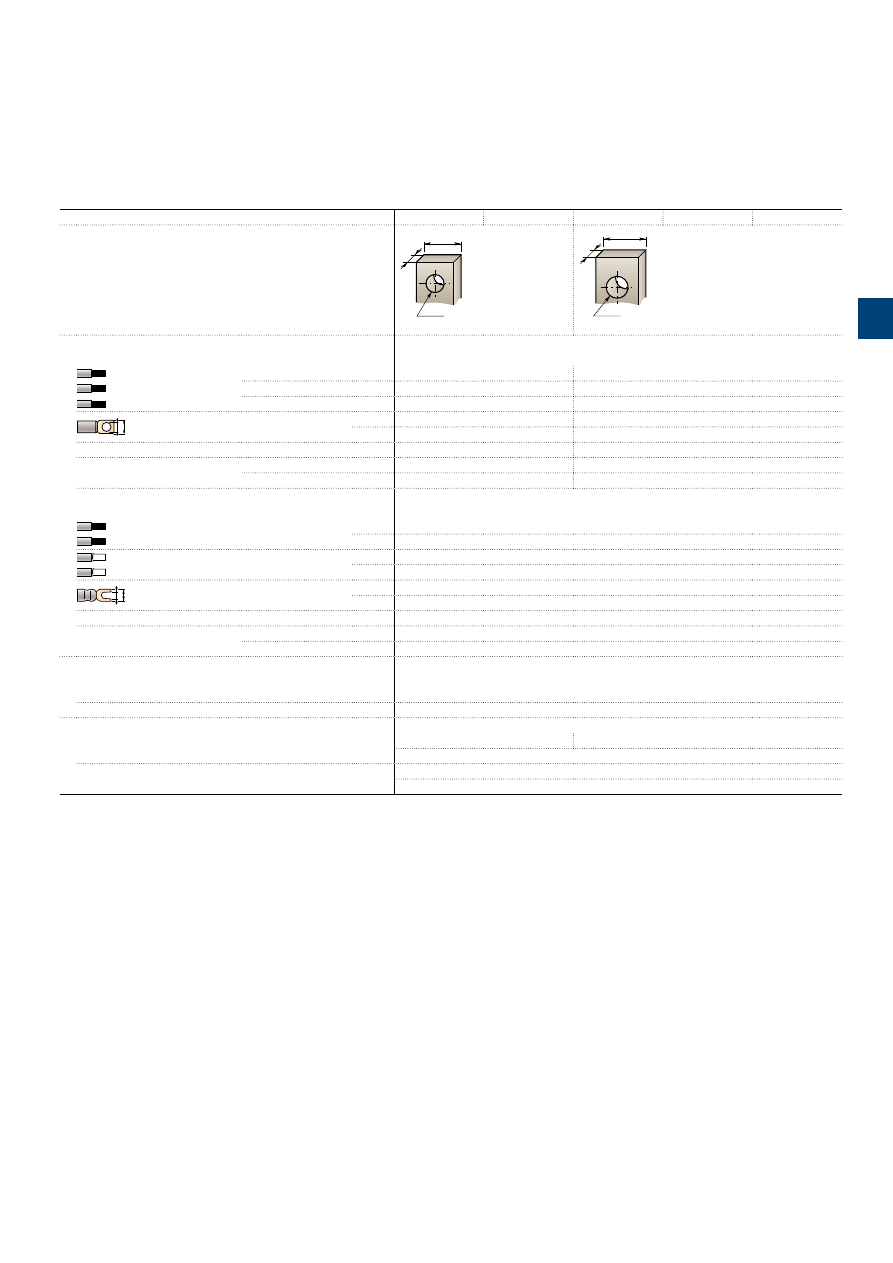

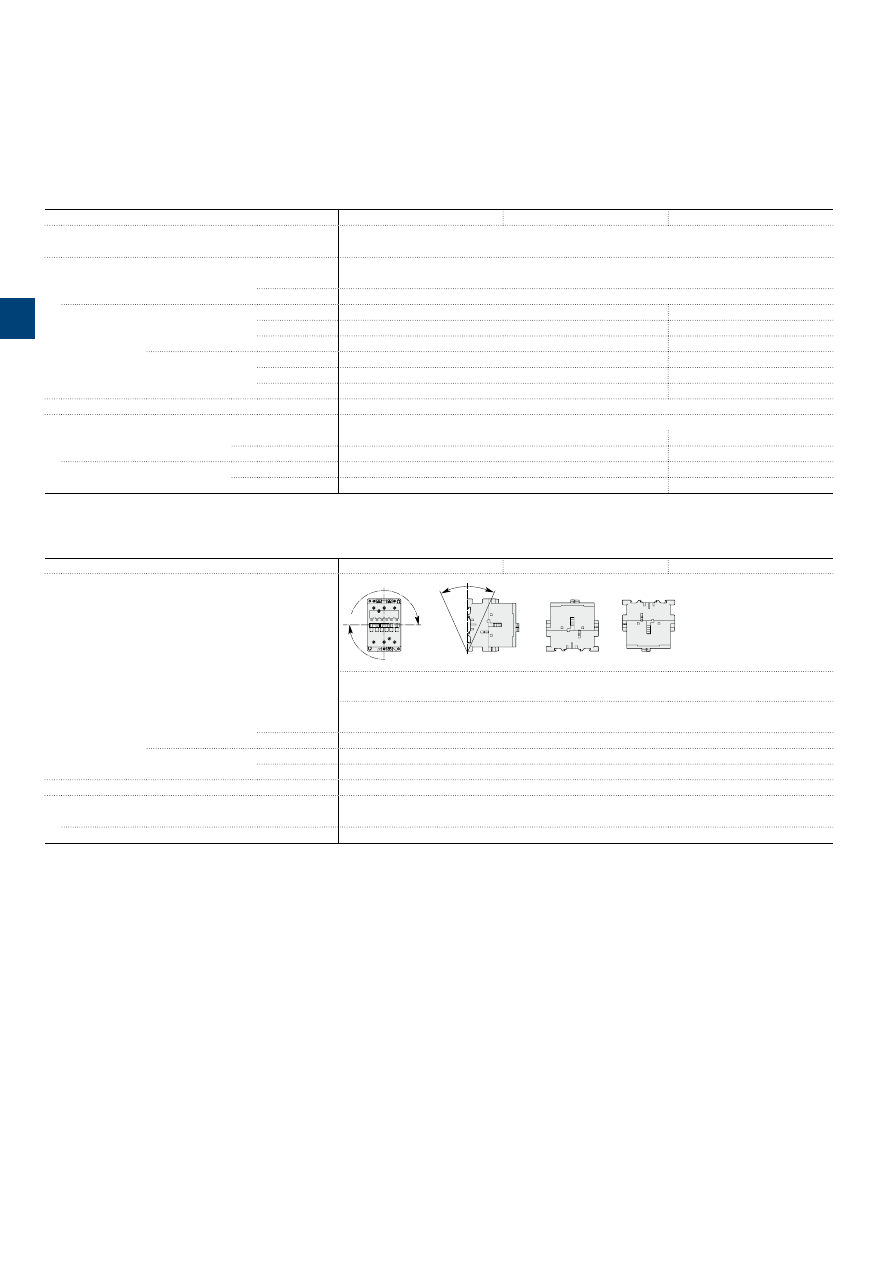

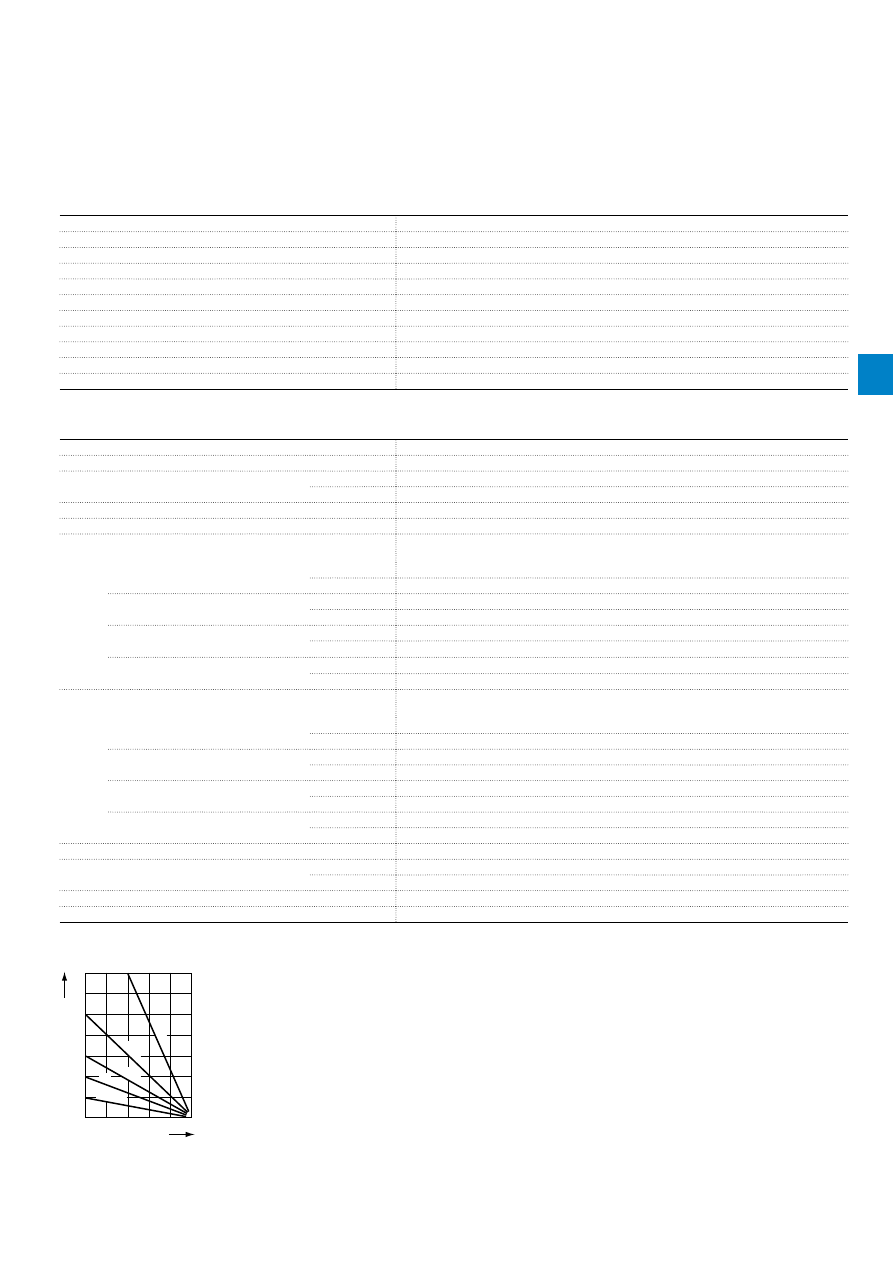

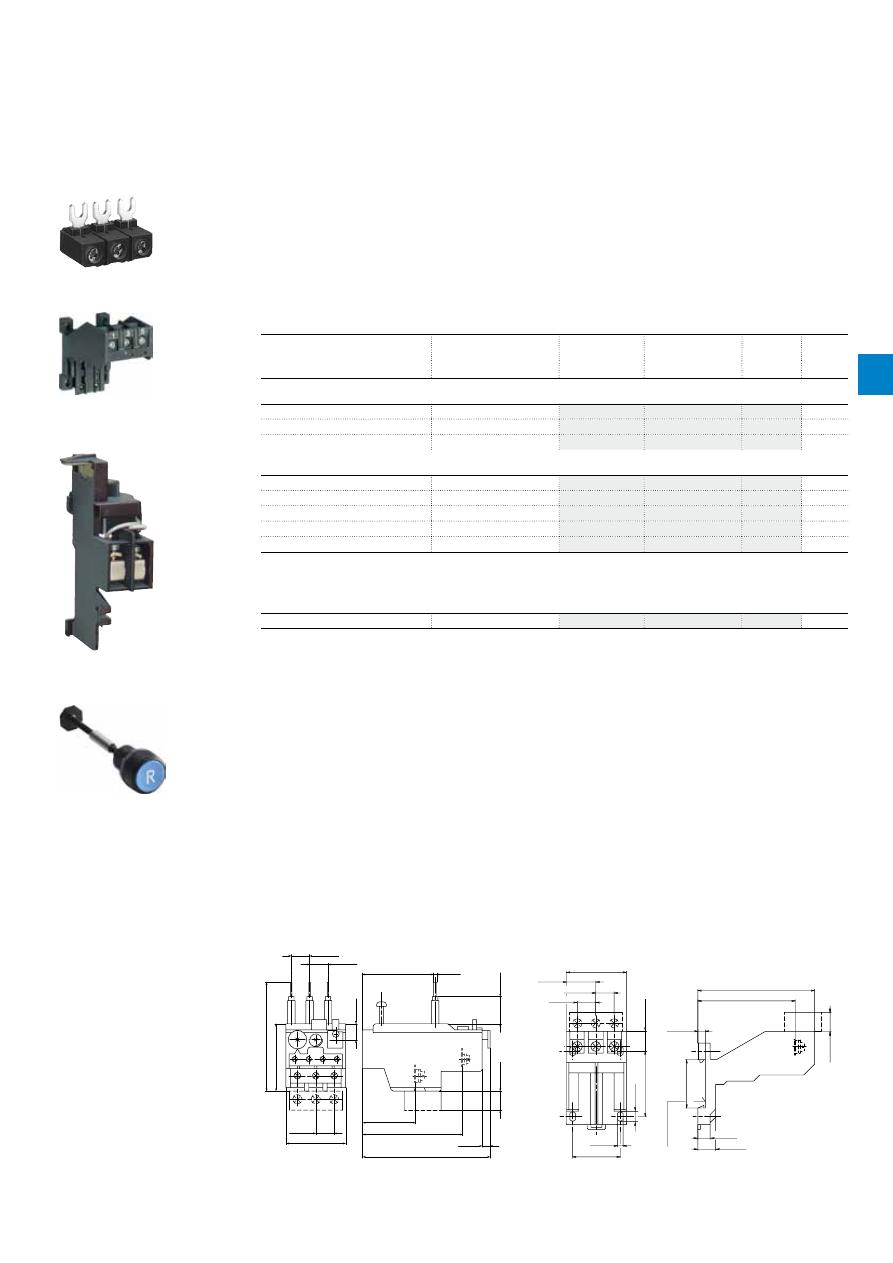

Main dimensions

mm,

inches

0.06"

0.07"

0.55"

3.54"

1.77"

0.55"

1.38"

0.22"

1.77"

2.3"

2.76"

1.71"

3.15"

1.1"

2.95"

1.5

1.7

14

14

90

45

35

5.5

45

57.8

70

43.5

80.1

27.5

75

2CDC242002F0010

1.77"

2.3"

1.38"

0.22"

2.75"

1.7"

3.15"

0.55"

2.95"

3.85"

1.77"

0.55"

0.06"

0.07"

1.1"

45

57.8

35

5.5

69.8

43.3

79.9

14

14

75

97.8

45

1.5

1.7

27.5

2CDC242001F0011

MS116 ≤ 16 A & MS116-HKF1-11 ≤ 16 A

MS116 ≥ 20 A & MS116-HKF1-11 ≥ 20 A

2

2C

D

C

13

10

3

9

C

0

2

01

ABB

|

2

/5

MS116 manual motor starters

Technical data

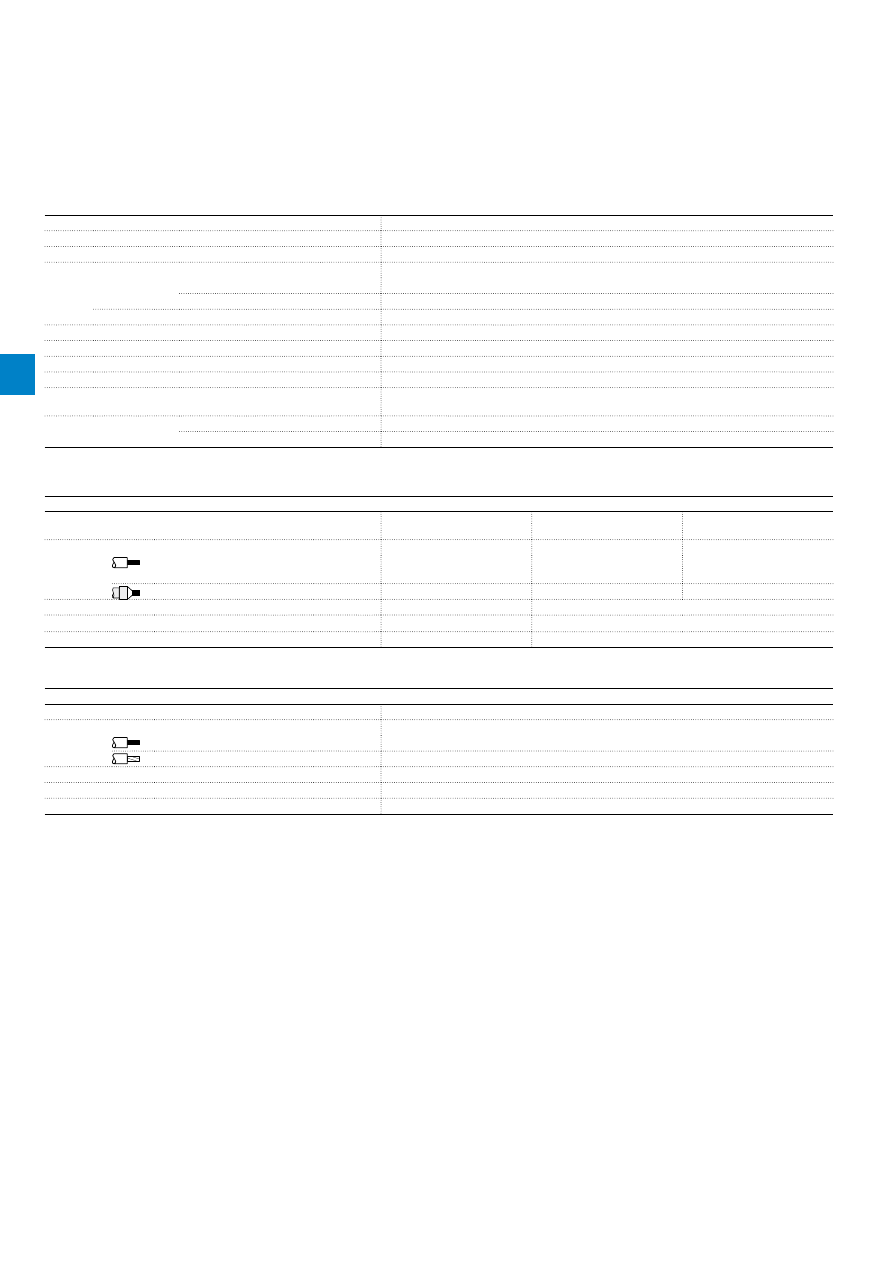

Main circuit – Utilization characteristics according to IEC/EN

Type

MS116

Standards

IEC/EN 60947–2, IEC/EN 60947-4-1, IEC/EN 60947-1

Rated operational voltage U

e

690 V AC

Rated frequency

50/60 Hz

Trip class

10A

Number of poles

3

Duty time

100 %

Mechanical durability

100000 cycles

Electrical durability

up to 16 A

100000 cycles

20 ... 32 A

50000 cycles

Rated impulse withstand voltage U

imp

6 kV

Rated insulation voltage U

i

690 V AC

Rated operational current I

e

See ordering details

Rated instantaneous short-circuit current setting I

i

See ordering details

Rated service short-circuit breaking capacity I

cs

See table "Short-circuit breaking capacity and back-up fuses"

Rated ultimate short-circuit breaking capacity I

cu

See table "Short-circuit breaking capacity and back-up fuses"

Short-circuit breaking capacity and back-up fuses

l

CS

Rated service short-circuit breaking capacity

l

CU

Rated ultimate short-circuit breaking capacity

I

CC

Prospective short-circuit current at installation location

Note: Maximum rated current of the back-up fuses if I

CC

> I

CS

Type

230 V AC

400 V AC

440 V AC

500 V AC

690 V AC

I

CS

kA

I

CU

kA

gG, aM

A

I

CS

kA

I

CU

kA

gG, aM

A

I

CS

kA

I

CU

kA

gG, aM

A

I

CS

kA

I

CU

kA

gG, aM

A

I

CS

kA

I

CU

kA

gG, aM

A

MS116-0.16

No back-up fuse required up to I

CC

= 50 kA

No back-up fuse required up to I

CC

= 30 kA

MS116-0.25

MS116-0.4

MS116-0.63

MS116-1.0

MS116-1.6

MS116-2.5

10

10

25

10

10

25

5

5

25

MS116-4.0

6

6

25

6

6

25

2

2

25

MS116-6.3

6

6

63

6

6

63

2

2

40

MS116-10

6

6

63

6

6

63

2

2

50

MS116-12

25

25

80

25

25

80

6

6

63

6

6

63

2

2

50

MS116-16

16

16

80

16

16

80

6

6

63

4

4

63

2

2

63

MS116-20

10

15

-

10

15

-

3

6

-

3

4

-

2

2

-

MS116-25

10

15

-

10

15

-

3

6

-

3

4

-

2

2

-

MS116-32

10

10

-

10

10

-

3

6

-

3

4

-

2

2

-

MS116-10: No need for back-up fuse in networks with a prospective current of up to 50 kA at 400 V.

MS116-16: No need for back-up fuse in networks with a prospective current of up to 16 kA at 400 V.

With an approbiate 80 A type gG fuse the device can be used in a network with a prospective current of up to 100 kA.

MS116-32: No need for back-up fuse in networks with a prospective current of up to 10 kA at 400 V.

2

2C

D

C

13

10

3

9

C

0

2

01

2

/6 |

ABB

MS116 manual motor starters

Technical data

Main circuit – Utilization characteristics according to UL/CSA

Type

MS116

Standards

UL 508, CSA 22.2 No. 14

Maximum operational voltage

600 V AC

Manual motor controller ratings

See table "UL 508 – Manual motor controller"

Trip rating

125 % FLA

Motor ratings

Horse power

See table "Motor rating, three phase"

Full load amps (FLA)

See table "Motor rating, three phase"

Locked rotor amps (LRA)

See table "Motor rating, three phase"

Motor rating, three phase

hp

Horse power

FLA Full load amps

LRA Locked rotor amps

Type

220-240 V AC

440-480 V AC

500-600 V AC

hp

FLA

LRA

hp

FLA

LRA

hp

FLA

LRA

MS116-0.16

-

0.16

0.96

-

0.16

0.96

-

0.16

0.96

MS116-0.25

-

0.25

1.5

-

0.25

1.5

-

0.25

1.5

MS116-0.4

-

0.4

2.4

-

0.4

2.4

-

0.4

2.4

MS116-0.63

-

0.63

3.78

-

0.63

3.78

-

0.63

3.78

MS116-1.0

-

1.0

6.0

1.0

6.0

1/2

0.9

8

MS116-1.6

-

1.6

9.6

3/4

1.6

12.5

3/4

1.3

10

MS116-2.5

1/2

2.2

20

1

2.1

15

1-1/2

2.4

16

MS116-4.0

1

4.2

30

2

3.4

25

3

3.9

25.6

MS116-6.3

1-1/2

6.4

40

3

4.8

32

5

6.1

36.8

MS116-10

3

9.6

64

5

7.6

46

7-1/2

9

50.8

MS116-12

3

9.6

64

7-1/2

11

63.5

10

11

64.8

MS116-16

5

15.2

92

10

14

81

10

11

64.8

MS116-20

5

15.2

92

10

14

81

15

17

93

MS116-25

7-1/2

22

127

15

21

116

20

22

116

MS116-32

10

28

162

20

27

145

25

27

146

UL 508 – Manual motor controller

Type

Maximum fuse type K5 o. RK5

per UL/NEC

Maximum short-circuit current

for motor disconnect

1)

for group installation

480 V / 600 V

A

480 V

kA

600 V

kA

480 V

kA

600 V

kA

MS116-0.16

100

30

5

30

5

MS116-0.25

100

30

5

30

5

MS116-0.4

100

30

5

30

5

MS116-0.63

100

30

5

30

5

MS116-1.0

100

30

5

30

5

MS116-1.6

100

30

5

30

5

MS116-2.5

100

30

5

30

5

MS116-4.0

100

18

5

18

5

MS116-6.3

100

18

5

18

5

MS116-10

100

18

5

18

5

MS116-12

100

18

5

18

5

MS116-16

100

18

5

18

5

MS116-20

100

18

5

18

5

MS116-25

100

18

5

18

5

MS116-32

100

18

5

18

5

1)

Suitable as motor disconnect only when provided with padlock SA1 or SA3...

2

2C

D

C

13

10

3

9

C

0

2

01

ABB

|

2

/7

MS116 manual motor starters

Technical data

General technical data

Type

MS116

Pollution degree

3

Phase loss sensitivity

Yes

Disconnect function acc. to IEC/EN 60947-2

Yes

Ambient air temperature

Operation

Open - compensated

-25 ... +55 °C

Open

-25 ... +70 °C

Enclosed (IB132)

0 ... +40 °C

Storage

-50 ... +80 °C

Ambient air temperature compensation

Acc. to IEC/EN60947-4-1

Maximum operating altitude permissible

2000 m

Resistance to shock acc. to IEC 60068-2-27

25g / 11 ms

Resistance to vibrations acc. to IEC 60068-2-6

5g / 3 ... 150 Hz

Mounting position

Position 1-6 (optional for single mounting)

Mounting

DIN-rail (EN 60715)

Group mounting

On request

Minimum distance to other

units same type

Horizontal

0 mm

Vertical

150 mm

Minimum distance to

electrical conductive board

Horizontal, up to 400 V

0 mm

Horizontal, up to 690 V

> 1.5 mm

Vertical

75 mm

Degree of protection

Housing

IP20

Main circuit terminals

IP20

Connecting characteristics

Main circuit

Type

MS116 ≤ 16 A

MS116 ≥ 20 A

Connecting capacity

Rigid

1 or 2 x

1 ... 4 mm²

2.5 ... 6 mm²

Flexible with ferrule

1 or 2 x

0.75 ... 2.5 mm²

1 ... 6 mm²

Flexible with insulated ferrule

1 or 2 x

0.75 ... 2.5 mm²

1 ... 6 mm²

Flexible

1 or 2 x

0.75 ... 2.5 mm²

1 ... 6 mm²

Stranded acc. to UL/CSA

1 or 2 x

AWG 16-12

AWG 12-8

Flexible acc. to UL/CSA

1 or 2 x

AWG 16-12

AWG 12-8

Stripping length

9 mm

10 mm

Tightening torques

0.8 ... 1.2 Nm / 10 … 12 Ib.in

2.0 Nm / 18 Ib.in

Connection screw

M3.5 (Pozidriv 2 / 5.5 mm)

M4 (Pozidriv 2 / 6.5 mm)

2

2C

D

C

13

10

4

0

C

0

2

01

2

/8 |

ABB

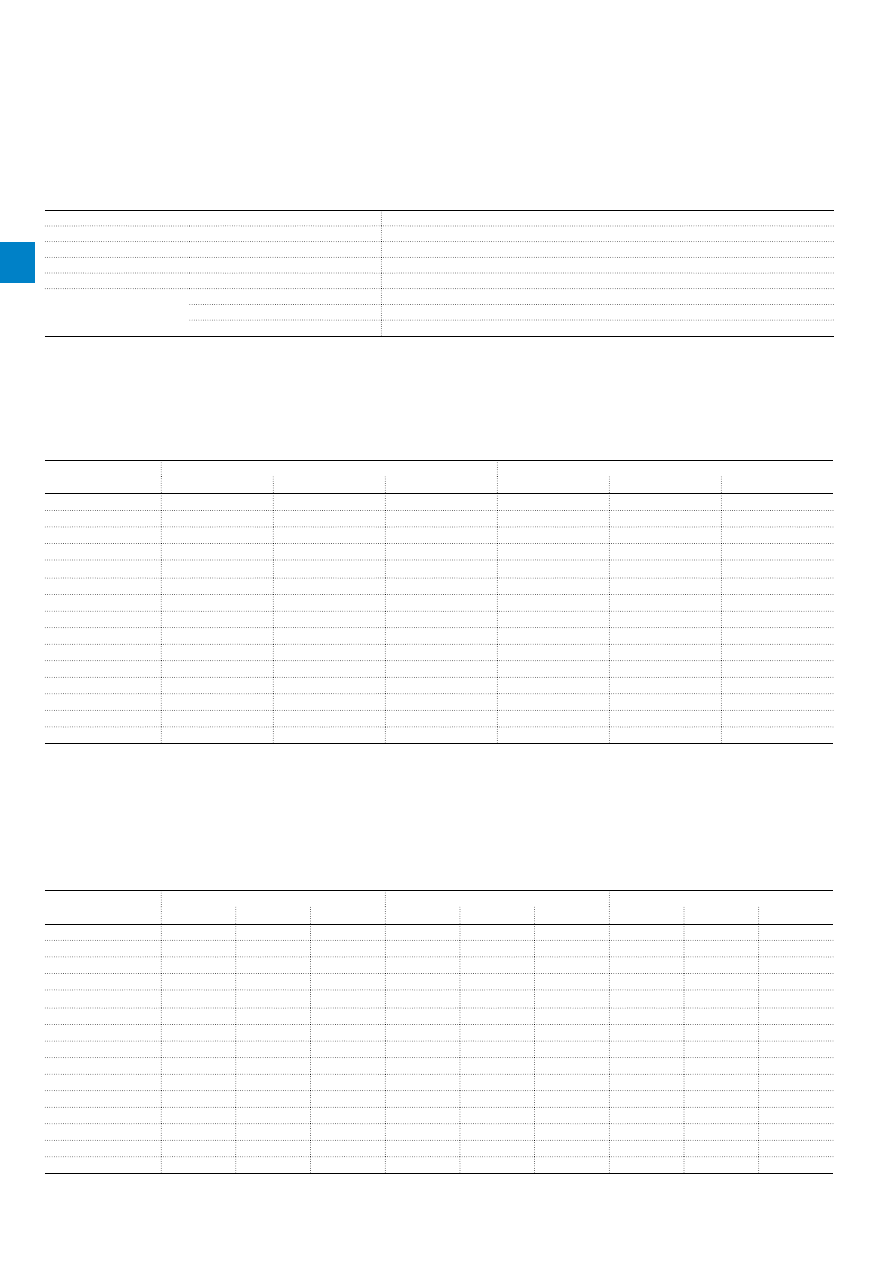

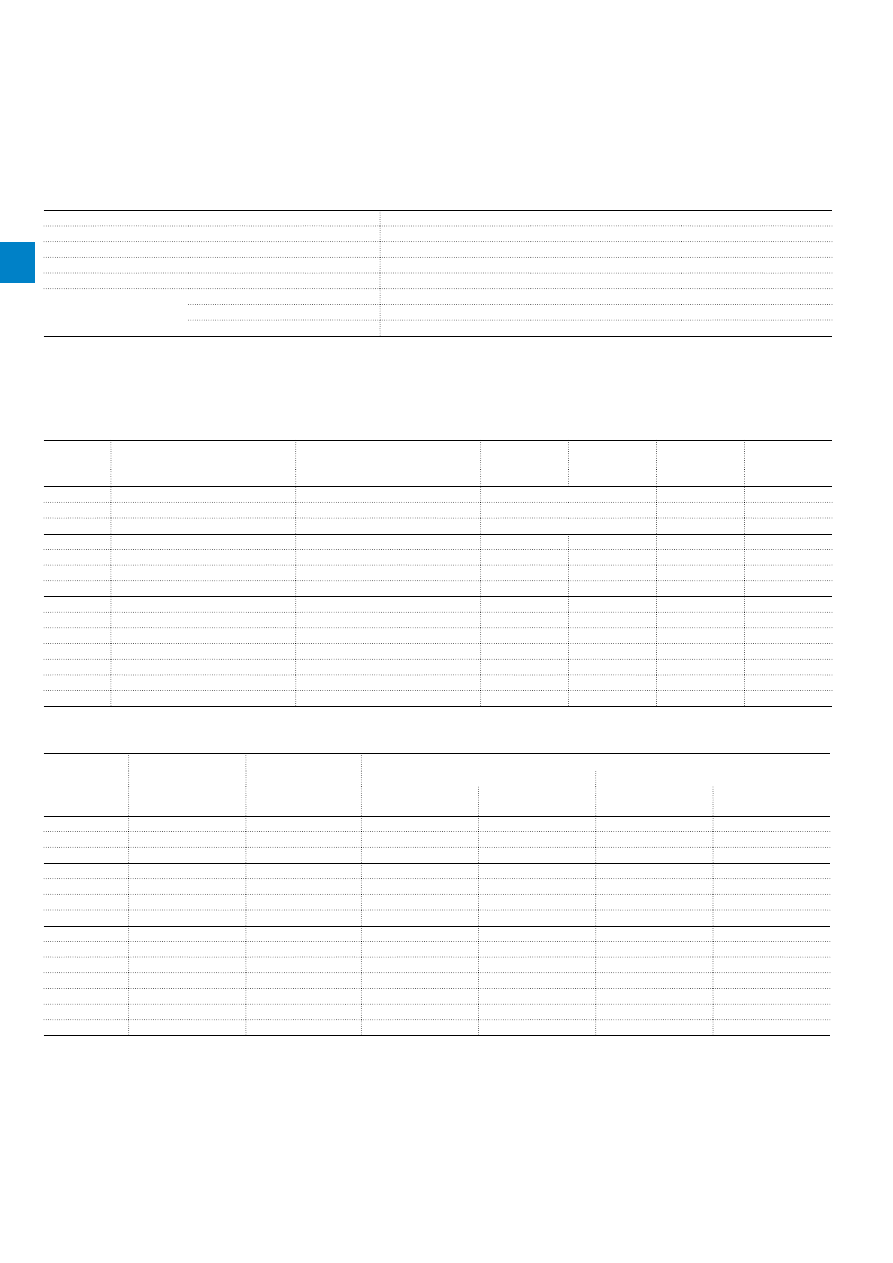

MS132 manual motor starters

0.10 to 32 A – with thermal and electromagnetic protection

Description

Manual motor starters (MMS) are protection devices for the main circuit. They combine motor control and

protection in a single device. MMS are used mainly to switch motors manually ON/OFF and protect them and

the installation fuse less against short-circuit, overload and phase failures. Fuse less protection with a manual

motor starter saves costs, space and ensures a quick reaction under short-circuit condition, by switching off

the motor within milliseconds.

MS132 is a compact and powerful range for motor protection up 15.5 kW (400 V) / 32 A in width of 45 mm.

Further features are the build-in disconnect function, temperature compensation, trip-free mechanism

and a rotary handle with a clear switch position indication. The manual motor starter is suitable for three-

and single-phase applications. The handle is lockable to protect against unauthorized changes. Auxiliary

contacts, signalling contacts, undervoltage releases, shunt trips, three-phase bus bars, power in-feed

blocks.

Ordering details

Rated

operational

power

400 V

AC-3

Setting range Short-circuit

breaking

capacity Ics at

400 V AC

Rated

instantaneous

short-circuit

current setting li

Type

Order code

Weight

(1 pce)

kW

A

kA

A

kg

0.03

0.10…0.16

100

1.56

MS132-0.16

0.215

0.06

0.16…0.25

100

2.44

MS132-0.25

0.215

0.09

0.25…0.40

100

3.90

MS132-0.4

0.215

0.12

0.40…0.63

100

6.14

MS132-0.63

0.215

0.25

0.63…1.00

100

11.50

MS132-1.0

0.215

0.55

1.00…1.60

100

18.40

MS132-1.6

0.265

0.75

1.60…2.50

100

28.75

MS132-2.5

0.265

1.5

2.50…4.00

100

50.00

MS132-4.0

0.265

2.2

4.00…6.30

100

78.75

MS132-6.3

0.265

4.0

6.30…10.0

100

150

MS132-10

0.265

5.5

8.00…12.0

100

180

MS132-12

0.310

7.5

10.0…16.0

100

240

MS132-16

0.310

9.0

16.0…20.0

100

300

MS132-20

0.310

12.5

20.0…25.0

50

375

MS132-25

0.310

15.5

25.0…32.0

25

480

MS132-32

0.310

Auxiliary contacts mounted on the front (1 N.O. + 1 N.C.)

0.03

0.10...0.16

100

1.56

MS132-0.16-HKF1-11 1SAM350005R1001

0.231

0.06

0.16...0.25

100

2.44

MS132-0.25-HKF1-11 1SAM350005R1002

0.231

0.09

0.25...0.40

100

3.90

MS132-0.4-HKF1-11

0.231

0.12

0.40...0.63

100

6.14

MS132-0.63-HKF1-11 1SAM350005R1004

0.231

0.25

0.63...1.00

100

11.50

MS132-1.0-HKF1-11

0.231

0.55

1.00...1.60

100

18.40

MS132-1.6-HKF1-11

0.281

0.75

1.60...2.50

100

28.75

MS132-2.5-HKF1-11

0.281

1.5

2.50...4.00

100

50.00

MS132-4.0-HKF1-11

0.281

2.2

4.00...6.30

100

78.75

MS132-6.3-HKF1-11

0.281

4.0

6.30...10.0

100

150

MS132-10.0-HKF1-11 1SAM350005R1010

0.281

5.5

8.00...12.0

100

180

MS132-12.0-HKF1-11 1SAM350005R1012

0.326

7.5

10.0...16.0

100

240

MS132-16.0-HKF1-11 1SAM350005R1011

0.326

9.0

16.0...20.0

100

300

MS132-20-HKF1-11

0.326

12.5

20.0...25.0

50

375

MS132-25-HKF1-11

0.326

15.5

25.0...32.0

25

480

MS132-32-HKF1-11

0.326

1SBC101232F0010

MS132-10

2CDC241001F0011

MS132-32

2CDC241014F0011

MS132-0.16-HKF1-11

2CDC241015F0011

MS132-32-HKF1-11

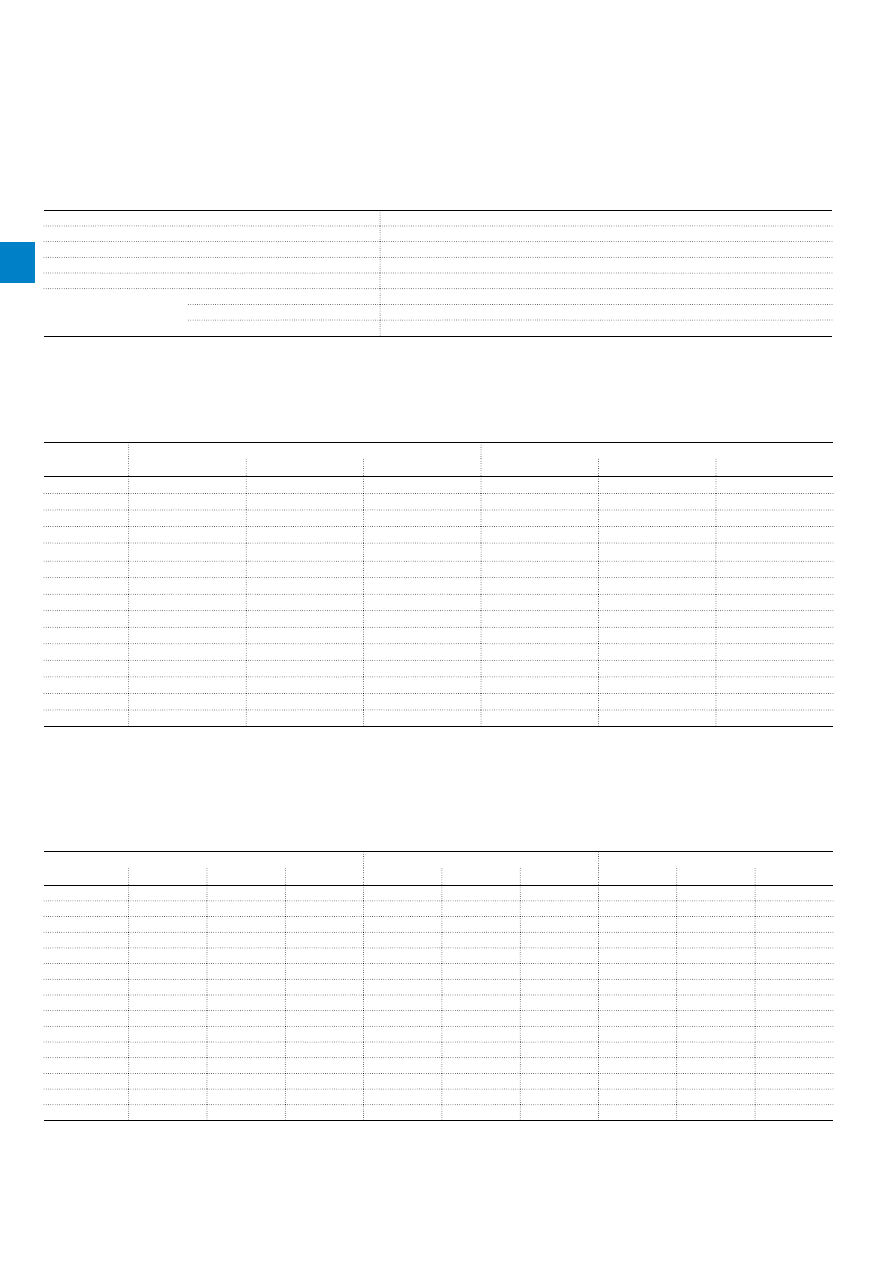

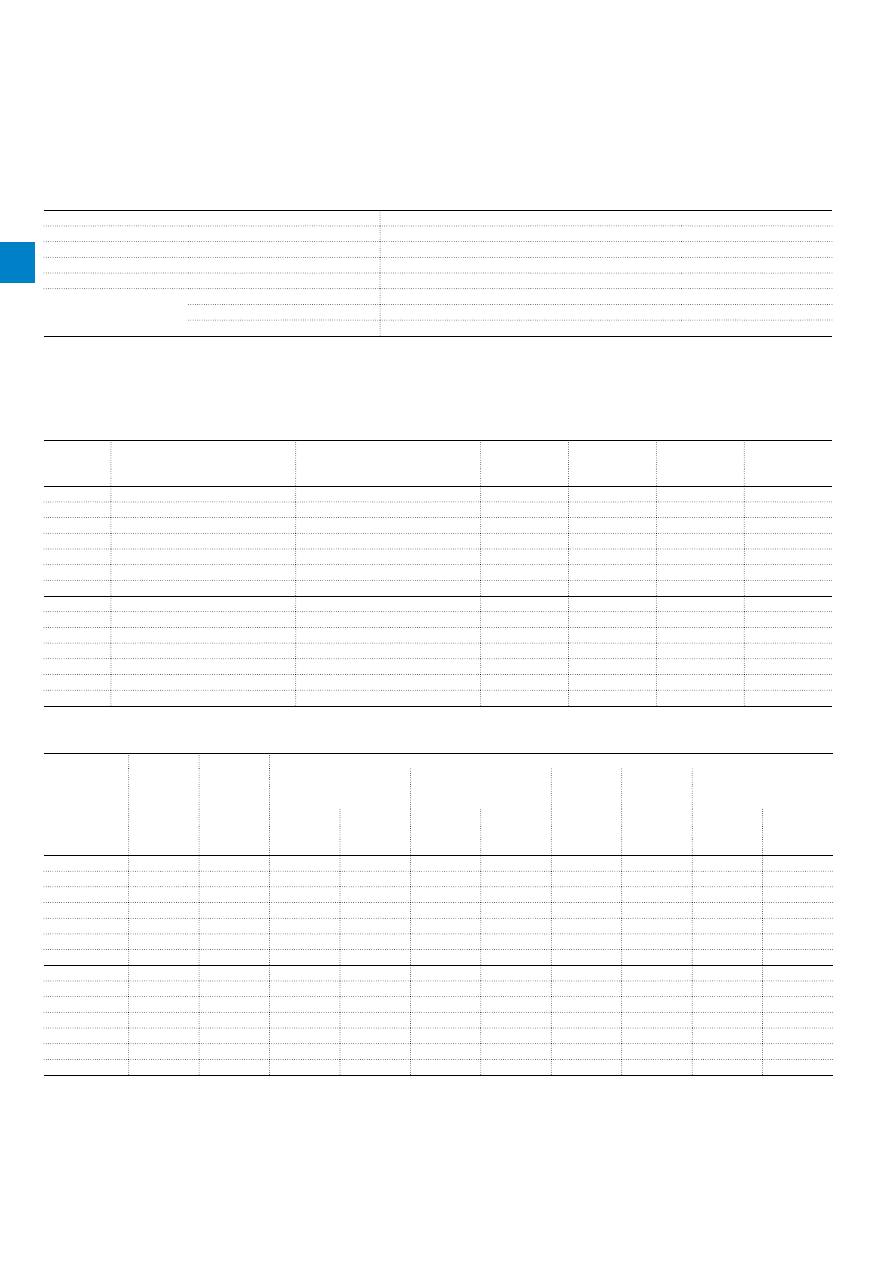

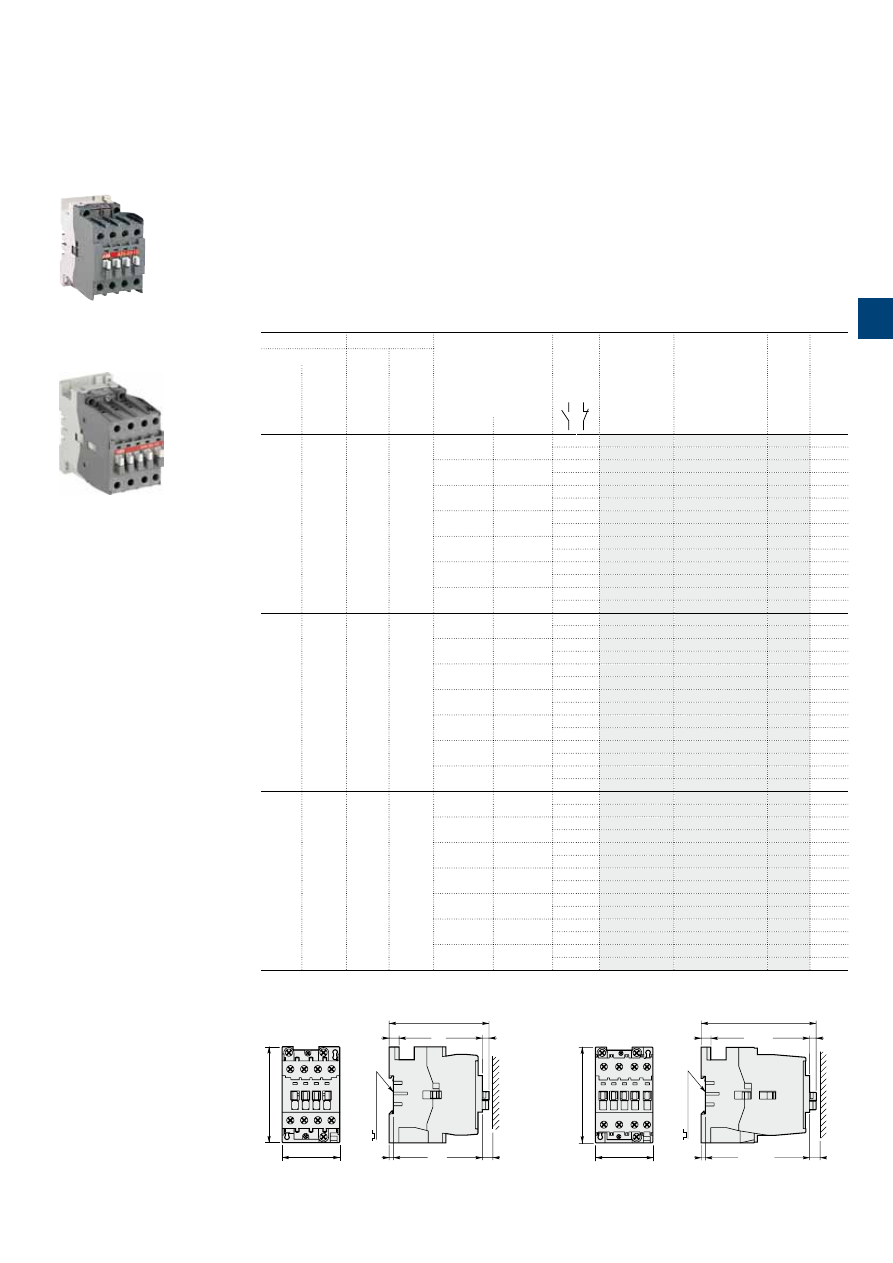

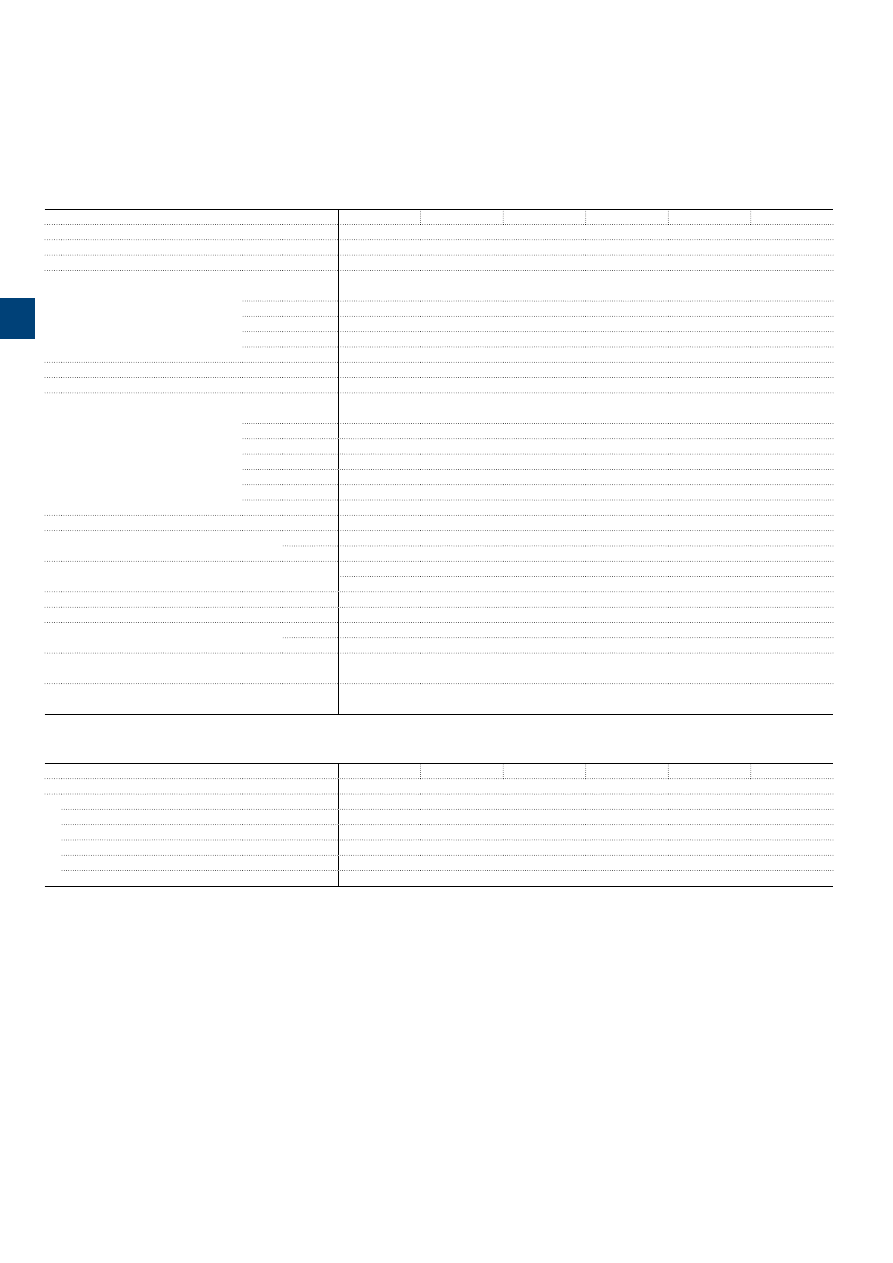

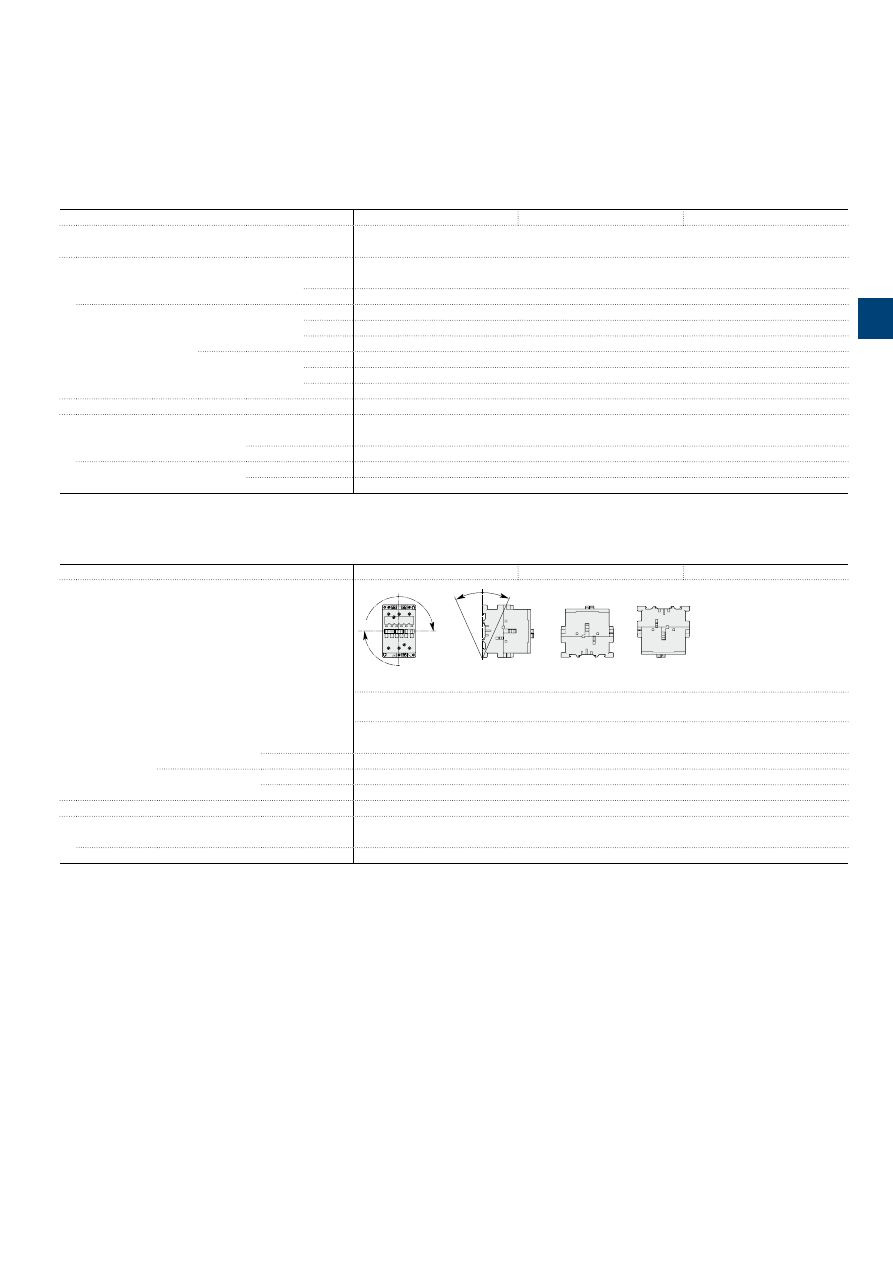

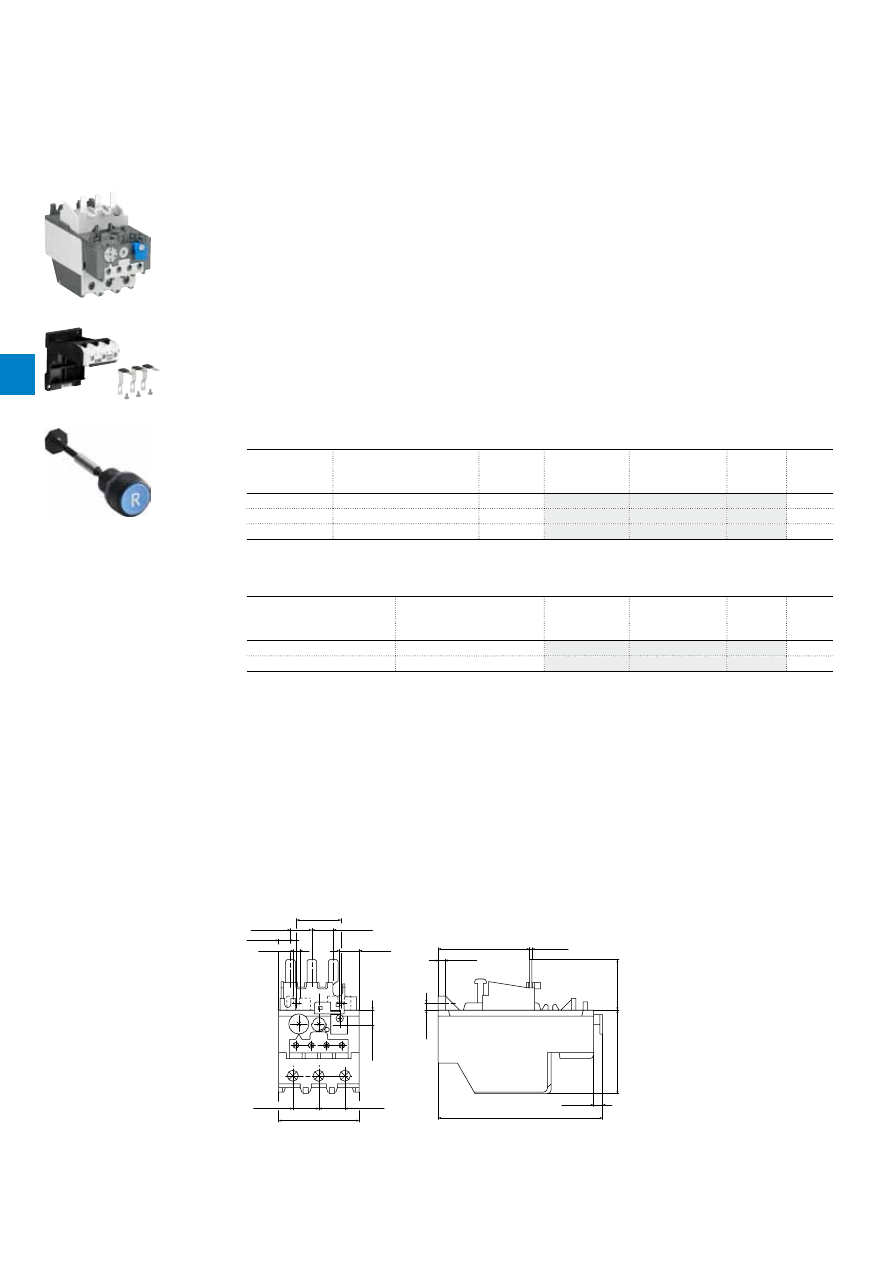

Main dimensions

mm,

inches

1.38"

0.1"

3.54"

2.95"

0.22"

0.06"

0.55"

1.77"

0.55"

2.85"

3.2"

1.71"

1.77"

35

1.7

90

75

5.5

1.5

14

45

14

72.4

81.25

43.5

45"

2CDC242015F0009

0.06"

0.22"

0.22"

2.84"

3.19"

0.1"

3.85"

1.77"

0.55"

0.55"

1.77"

2.95"

1.38"

1.5

5.5

43.3

72.2

81.05

1.7

97.8

45

14

14

45

75

35

2CDC242016F0009

MS132 ≤ 10 A

MS132 ≥ 12 A

2

2C

D

C

13

10

4

0

C

0

2

01

ABB

|

2

/9

MS132 manual motor starters

Technical data

Main circuit – Utilization characteristics according to IEC/EN

Type

MS132

Standards

IEC/EN 60947–2, IEC/EN 60947-4-1, IEC/EN 60947-1

Rated operational voltage U

e

690 V AC / 250 V DC

Rated frequency

DC, 50/60 Hz

Trip class

Number of poles

3

Duty time

100 %

Mechanical durability

100000 cycles

Electrical durability

50000 cycles

Rated impulse withstand voltage U

imp

6 kV

Rated insulation voltage U

i

690 V AC

Rated operational current I

e

See ordering details

Rated oprational current DC-5 I

e

3 conducting paths in series up to 250 V

See "Rated operational current I

e

"

Rated instantaneous short-circuit current setting I

i

See ordering details

Rated service short-circuit breaking capacity I

cs

See table "Short-circuit breaking capacity and back-up fuses"

Rated ultimate short-circuit breaking capacity I

cu

See table "Short-circuit breaking capacity and back-up fuses"

Rated service short-circuit breaking capacity DC I

cs

3 conducting paths in series up to 250 V

10 kA

Short-circuit breaking capacity and back-up fuses

l

CS

Rated service short-circuit breaking capacity

l

CU

Rated ultimate short-circuit breaking capacity

I

CC

Prospective short-circuit current at installation location

Note: Maximum rated current of the back-up fuses if I

CC

> I

CS

Type

230 V AC

400 V AC

440 V AC

500 V AC

690 V AC

I

CS

kA

I

CU

kA

gG, aM

A

I

CS

kA

I

CU

kA

gG, aM

A

I

CS

kA

I

CU

kA

gG, aM

A

I

CS

kA

I

CU

kA

gG, aM

A

I

CS

kA

I

CU

kA

gG, aM

A

MS132-0.16

No back-up fuse required up to I

CC

= 100 kA

MS132-0.25

MS132-0.4

MS132-0.63

MS132-1.0

MS132-1.6

MS132-2.5

MS132-4.0

20

20

35

20

20

35

3

3

32

MS132-6.3

20

20

63

20

20

63

3

3

50

MS132-10

20

20

100

20

20

100

3

3

50

MS132-12

20

20

100

20

20

100

3

3

63

MS132-16

20

20

125

20

20

125

3

3

63

MS132-20

20

20

125

20

20

125

3

3

80

MS132-25

50

50

125

50

50

125

20

20

125

10

10

125

3

3

100

MS132-32

25

50

125

25

50

125

20

20

125

10

10

125

3

3

100

MS132-16: No need for back-up fuse in networks with a prospective current of up to 100 kA at 400 V.

MS132-32: No need for back-up fuse in networks with a prospective current of up to 50 kA at 400 V.

With an approbiate 125 A type gG fuse the device can be used in a network with a prospective current of up to 100 kA.

2

2C

D

C

13

10

4

0

C

0

2

01

2

/10 |

ABB

MS132 manual motor starters

Technical data

Main circuit – Utilization characteristics according to UL/CSA

Type

MS132

Standards

UL 508, CSA 22.2 No. 14

Maximum operational voltage

600 V AC

Manual motor controller ratings

See table "UL 508 – Manual motor controller"

Trip rating

125 % FLA

Motor ratings

Horse power

See table "Motor rating, three phase"

Full load amps (FLA)

See table "Motor rating, three phase"

Locked rotor amps (LRA)

See table "Motor rating, three phase"

Motor rating, single phase

hp

Horse power

FLA Full load amps

LRA Locked rotor amps

Type

120 V AC

220-240 V AC

hp

FLA

LRA

hp

FLA

LRA

MS132-0.16

-

0.16

0.96

-

0.16

0.96

MS132-0.25

-

0.25

1.5

-

0.25

1.5

MS132-0.4

-

0.4

2.4

-

0.4

2.4

MS132-0.63

-

0.63

3.78

-

0.63

3.78

MS132-1.0

-

1

6

-

1

6

MS132-1.6

1.6

9.6

1/10

1.6

9.6

MS132-2.5

2.5

15

1/6

2.5

15

MS132-4.0

1/8

4

24

1/3

4

24

MS132-6.3

1/4

6.3

37.8

1/2

6.3

37.8

MS132-10

1/2

9.8

58.8

1-1/2

10

60

MS132-12

1/2

9.8

58.8

2

12

72

MS132-16

1

16

96

2

12

72

MS132-20

1-1/2

20

120

3

17

92

MS132-25

2

24

144

3

17

127

MS132-32

2

24

144

5

28

162

Motor rating, three phase

hp

Horse power

FLA Full load amps

LRA Locked rotor amps

Type

220-240 V AC

440-480 V AC

500-600 V AC

hp

FLA

LRA

hp

FLA

LRA

hp

FLA

LRA

MS132-0.16

-

0.16

0.96

-

0.16

0.96

-

0.16

0.96

MS132-0.25

-

0.25

1.5

-

0.25

1.5

-

0.25

1.5

MS132-0.4

-

0.4

2.4

-

0.4

2.4

-

0.4

2.4

MS132-0.63

-

0.63

3.78

-

0.63

3.78

-

0.63

3.78

MS132-1.0

-

1.0

6.0

-

1.0

6.0

1/2

1.0

6.0

MS132-1.6

-

1.6

9.6

3/4

1.6

9.6

3/4

1.6

9.6

MS132-2.5

1/2

2.5

15.0

1

2.5

15.0

1-1/2

2.5

15.0

MS132-4.0

1

4.0

24.0

2

4.0

24.0

3

3.9

26.0

MS132-6.3

1-1/2

6.3

37.8

3

4.8

32.0

5

6.1

37.0

MS132-10

3

9.6

64.0

5

7.6

46.0

7-1/2

9.0

51.0

MS132-12

3

9.6

64.0

7-1/2

11.0

64.0

10

11.0

65.0

MS132-16

5

15.2

92.0

10

14.0

81.0

10

11.0

65.0

MS132-20

5

15.2

92.0

10

14.0

81.0

15

17.0

93.0

MS132-25

7-1/2

22.0

127.0

15

21.0

116.0

20

22.0

116.0

MS132-32

10

28.0

162.0

20

27.0

145.0

25

27.0

146.0

2

2C

D

C

13

10

4

0

C

0

2

01

ABB

|

2

/11

MS132 manual motor starters

Technical data

UL 508 – Manual motor controller

Type

Maximum short-circuit current

for motor disconnect

for group installation

for self-protected combination motor

controller (type E) in combination with

feeder block S1-M3-xx

for tap conductor protection

480 V

kA

600 V

kA

480 V

kA

600 V

kA

480Y / 277 V

kA

600Y / 347 V

kA

480 V

kA

600 V

kA

MS132-0.16

65

47

65

47

65

47

65

47

MS132-0.25

65

47

65

47

65

47

65

47

MS132-0.4

65

47

65

47

65

47

65

47

MS132-0.63

65

47

65

47

65

47

65

47

MS132-1.0

65

47

65

47

65

47

65

47

MS132-1.6

65

47

65

47

65

47

65

47

MS132-2.5

65

47

65

47

65

47

65

47

MS132-4.0

65

18

65

30

65

18

65

18

MS132-6.3

65

18

65

30

65

18

65

18

MS132-10

65

18

65

30

65

18

65

18

MS132-12

30

18

30

30

30

-

30

18

MS132-16

30

18

30

30

30

-

30

18

MS132-20

30

18

30

30

30

-

30

18

MS132-25

30

18

30

30

30

-

30

18

MS132-32

30

18

30

30

30

-

30

18

General technical data

Type

MS132

Pollution degree

3

Phase loss sensitivity

Yes

Disconnect function acc. to IEC/EN 60947-2

Yes

Ambient air temperature

Operation

Open - compensated

-25 ... +60 °C

Open

-25 ... +70 °C

Enclosed (IB132)

0 ... +40 °C

Storage

-50 ... +70 °C

Ambient air temperature compensation

Acc. to IEC/EN60947-4-1

Maximum operating altitude permissible

2000 m

Resistance to shock acc. to IEC 60068-2-27

25g / 11 ms

Resistance to vibrations acc. to IEC 60068-2-6

5g / 3 ... 150 Hz

Mounting position

Position 1-6 (optional for single mounting)

Mounting

DIN-rail (EN 60715)

Group mounting

On request

Minimum distance to other

units same type

Horizontal

0 mm

Vertical

150 mm

Minimum distance to

electrical conductive board

Horizontal, up to 400 V

0 mm

Horizontal, up to 690 V

> 1.5 mm

Vertical

75 mm

Degree of protection

Housing

IP20

Main circuit terminals

IP20

Connecting characteristics

Main circuit

Type

MS132-0.16 … MS132-10

MS132-12 … MS132-16

MS132-20 … MS132-32

Connecting capacity

Rigid

1 or 2 x

1 ... 4 mm²

1 ... 4 mm²

2.5 ... 6 mm²

Flexible with ferrule

1 or 2 x

1 ... 4 mm²

1 ... 4 mm²

2.5 ... 6 mm²

Flexible with insulated ferrule

1 or 2 x

1 ... 4 mm²

1 ... 4 mm²

2.5 ... 6 mm²

Flexible

1 or 2 x

1 ... 4 mm²

1 ... 4 mm²

2.5 ... 6 mm²

Stranded acc. to UL/CSA

1 or 2 x

AWG 16-12

AWG 16-12

AWG 12-8

Flexible acc. to UL/CSA

1 or 2 x

AWG 16-12

AWG 16-12

AWG 12-8

Stripping length

9 mm

10 mm

10 mm

Tightening torques

0.8 ... 1.2 Nm / 10 … 12 Ib.in 1.5 Nm / 14 Ib.in

2.0 Nm / 18 Ib.in

Connection screw

M3.5 (Pozidriv 2)

M4 (Pozidriv 2)

M4 (Pozidriv 2)

2

2C

D

C

13

10

36C

0

2

01

2

/12 |

ABB

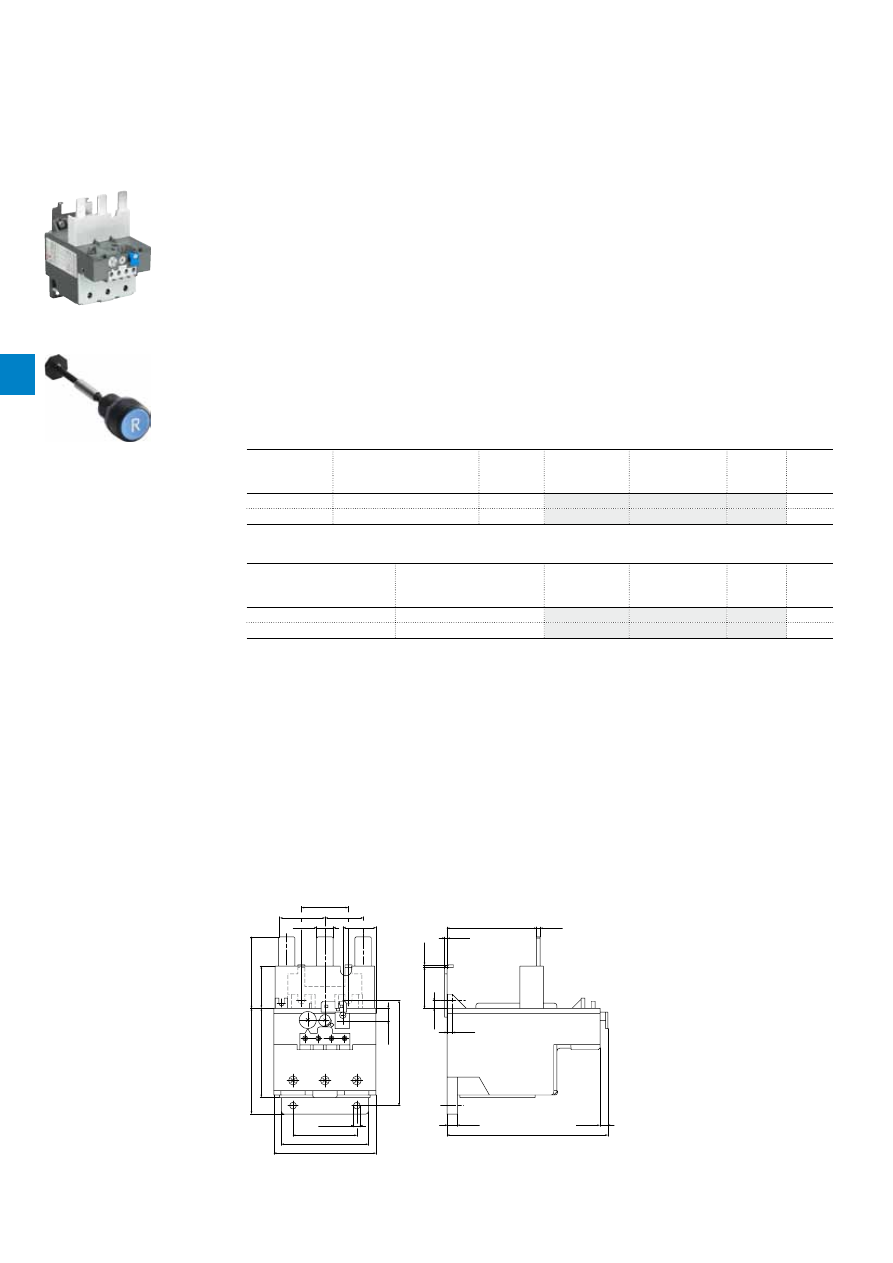

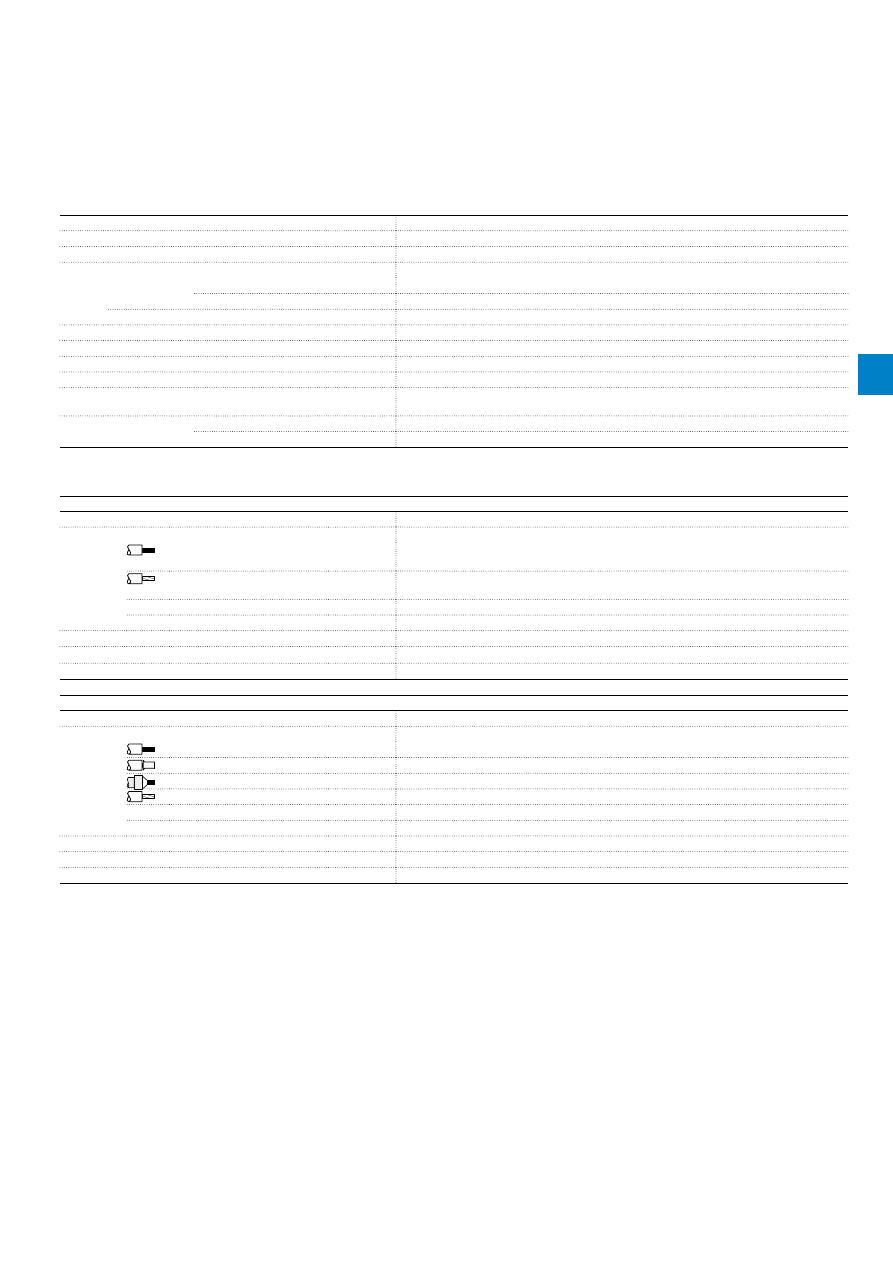

MO132 manual motor starters magnetic only

0.16 to 32 A – with electromagnetic protection

Description

Manual motor starters magnetic only are electromechanical protection devices for the main circuit. They are

used mainly to switch motors manually ON/OFF and protect them fuse less against short-circuit.

Fuse less protection with a manual motor starter saves costs, space and ensures a quick reaction under

short-circuit condition, by switching off the motor within milliseconds. Fuse less starter combinations are setup

together with contactors and overload relays.

Ordering details

Rated

operational

power

400 V

AC-3

(1)

Rated

operational

current

Short-circuit

breaking

capacity Ics at

400 V AC

Rated

instantaneous

short-circuit

current setting li

Type

Order code

Weight

(1 pce)

kW

A

kA

A

kg

0.03

0.16

100

1.56

MO132-0.16

0.215

0.06

0.25

100

2.44

MO132-0.25

0.215

0.09

0.40

100

3.90

MO132-0.4

0.215

0.12

0.63

100

6.14

MO132-0.63

0.215

0.25

1.0

100

11.50

MO132-1.0

0.215

0.55

1.6

100

18.40

MO132-1.6

0.265

0.75

2.5

100

28.75

MO132-2.5

0.265

1.5

4.0

50

50.00

MO132-4.0

0.265

2.2

6.3

50

78.75

MO132-6.3

0.265

4.0

10

50

125.00

MO132-10

0.265

5.5

12

50

150.00

MO132-12

0.310

7.5

16

50

200.00

MO132-16

0.310

9.0

20

50

250.00

MO132-20

0.310

12.5

25

50

312.50

MO132-25

0.310

15.5

32

25

400.00

MO132-32

0.310

(1) For overload protection of motors, an appropriate thermal or electronic overload relay must be used.

2CDC241009F0011

MO132-6.3

2CDC241008F0011

MO132-32

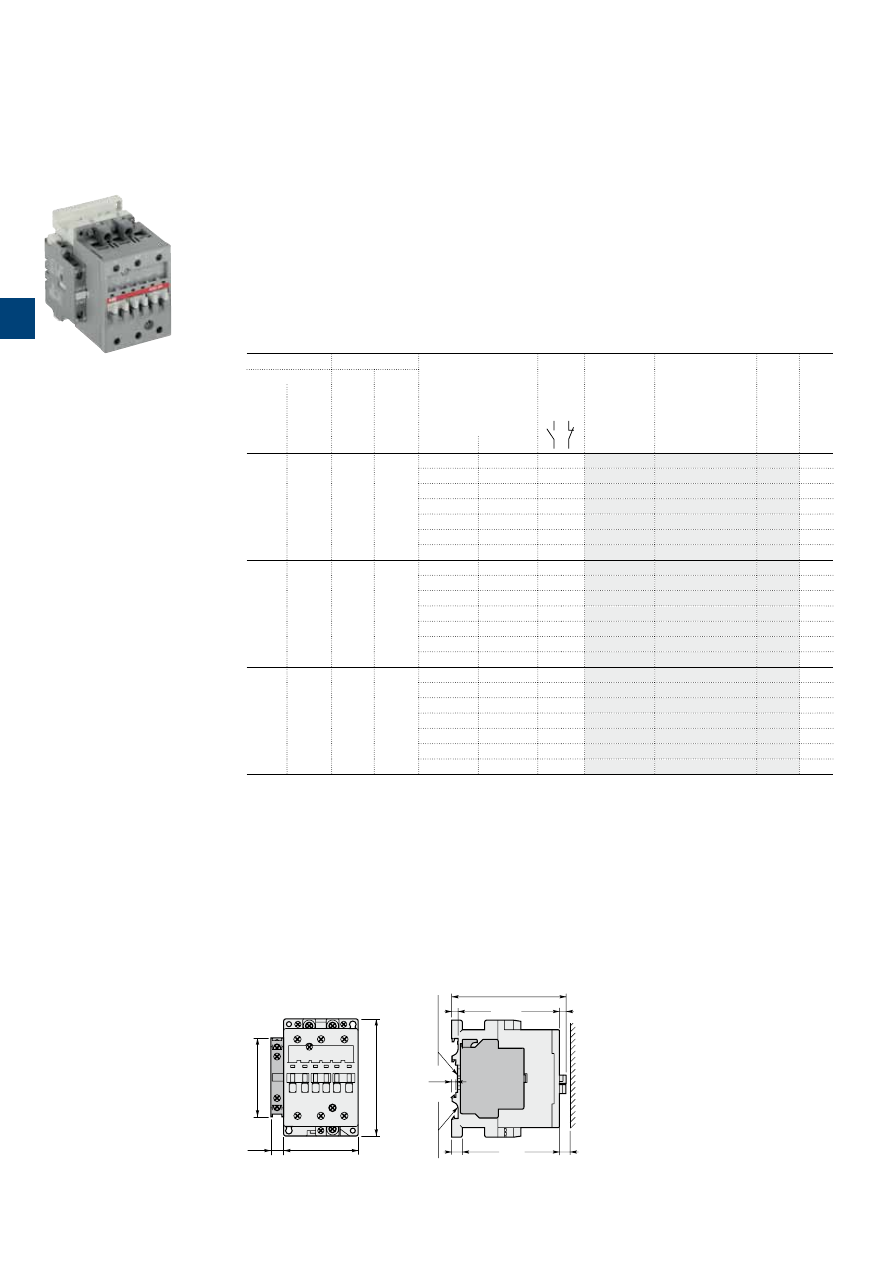

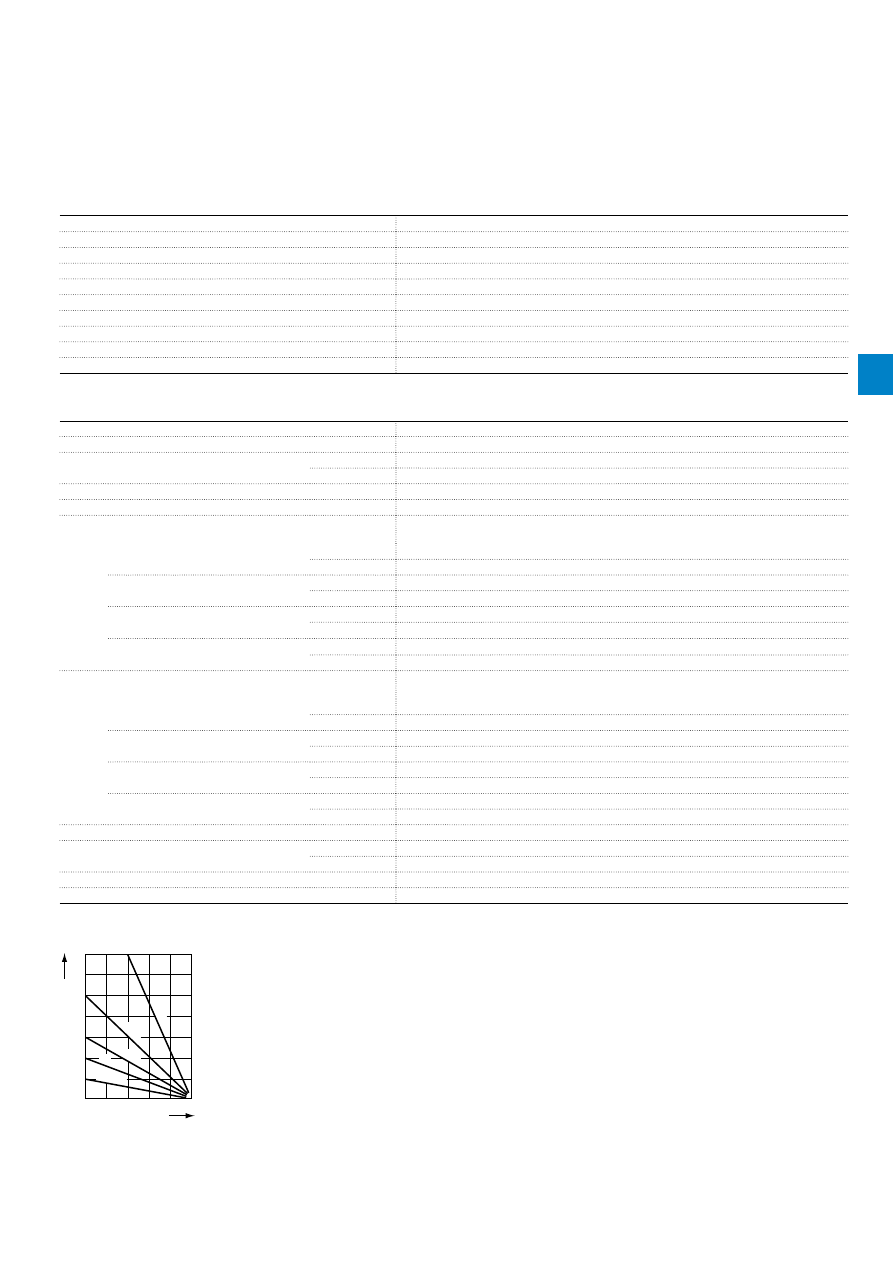

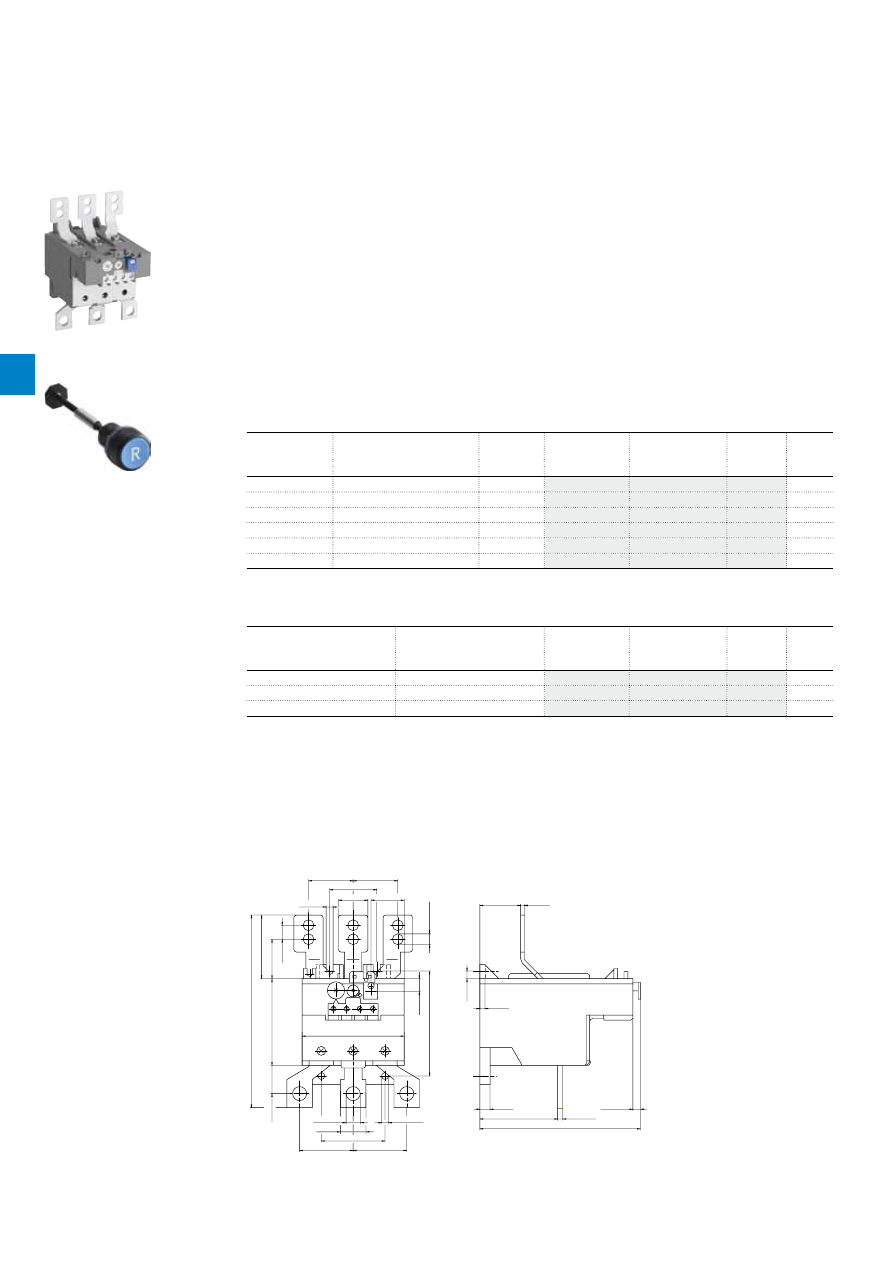

Main dimensions

mm,

inches

1.38"

0.1"

3.54"

2.95"

0.22"

0.06"

0.55"

1.77"

0.55"

2.85"

3.2"

1.71"

1.77"

35

1.7

90

75

5.5

1.5

14

45

14

72.4

81.25

43.5

45"

2CDC242005F0011

0.06"

0.22"

0.22"

2.84"

3.19"

0.1"

3.85"

1.77"

0.55"

0.55"

1.77"

2.95"

1.38"

1.5

5.5

43.3

72.2

81.05

1.7

97.8

45

14

14

45

75

35

2CDC242006F0011

MO132 ≤ 10 A

MO132 ≥ 12 A

2

2C

D

C

13

10

36C

0

2

01

ABB

|

2

/13

MO132 manual motor starters magnetic only

Technical data

Main circuit – Utilization characteristics according to IEC/EN

Type

MO132

Standards

IEC/EN 60947–2, IEC/EN 60947-4-1, IEC/EN 60947-1

Rated operational voltage U

e

690 V AC

Rated frequency

50/60 Hz

Number of poles

3

Duty time

100 %

Mechanical durability

100000 cycles

Electrical durability

50000 cycles

Rated impulse withstand voltage U

imp

6 kV

Rated insulation voltage U

i

690 V AC

Rated operational current I

e

See ordering details

Rated instantaneous short-circuit current setting I

i

See ordering details

Rated service short-circuit breaking capacity I

cs

See table "Short-circuit breaking capacity and back-up fuses"

Rated ultimate short-circuit breaking capacity I

cu

See table "Short-circuit breaking capacity and back-up fuses"

Short-circuit breaking capacity and back-up fuses

l

CS

Rated service short-circuit breaking capacity

l

CU

Rated ultimate short-circuit breaking capacity

I

CC

Prospective short-circuit current at installation location

Note: Maximum rated current of the back-up fuses if I

CC

> I

CS

Type

230 V AC

400 V AC

440 V AC

500 V AC

690 V AC

I

CS

kA

I

CU

kA

gG, aM

A

I

CS

kA

I

CU

kA

gG, aM

A

I

CS

kA

I

CU

kA

gG, aM

A

I

CS

kA

I

CU

kA

gG, aM

A

I

CS

kA

I

CU

kA

gG, aM

A

MO132-0.16

No back-up fuse required up to I

CC

= 100 kA

MO132-0.25

MO132-0.4

MO132-0.63

MO132-1.0

MO132-1.6

MO132-2.5

MO132-4.0

20

20

35

20

20

35

3

3

32

MO132-6.3

20

20

63

20

20

63

3

3

50

MO132-10

20

20

100

20

20

100

3

3

50

MO132-12

20

20

100

20

20

100

3

3

63

MO132-16

20

20

125

20

20

125

3

3

63

MO132-20

20

20

125

20

20

125

3

3

80

MO132-25

50

50

125

50

50

125

10

10

125

10

10

125

3

3

100

MO132-32

25

50

125

25

50

125

10

10

125

10

10

125

3

3

100

MO132-20: No need for back-up fuse in networks with a prospective current of up to 100 kA at 400 V.

MO132-32: No need for back-up fuse in networks with a prospective current of up to 50 kA at 400 V.

With an approbiate 125 A type gG fuse the device can be used in a network with a prospective current of up to 100 kA.

2

2C

D

C

13

10

36C

0

2

01

2

/14 |

ABB

MO132 manual motor starters magnetic only

Technical data

Main circuit – Utilization characteristics according to UL/CSA

Type

MO132

Standards

UL 508, CSA 22.2 No. 14

Maximum operational voltage

600 V AC

Manual motor controller ratings

See table "UL 508 – Manual motor controller"

Trip rating

125 % FLA

Motor ratings

Horse power

See table "Motor rating, three phase"

Full load amps (FLA)

See table "Motor rating, three phase"

Locked rotor amps (LRA)

See table "Motor rating, three phase"

Motor rating, single phase

hp

Horse power

FLA Full load amps

LRA Locked rotor amps

Type

120 V AC

220 ... 240 V AC

hp

FLA

LRA

hp

FLA

LRA

MO132-0.16

-

0.16

0.96

-

0.16

0.96

MO132-0.25

-

0.25

1.5

-

0.25

1.5

MO132-0.4

-

0.4

2.4

-

0.4

2.4

MO132-0.63

-

0.63

3.78

-

0.63

3.78

MO132-1.0

-

1

6

-

1

6

MO132-1.6

1.6

9.6

1/10

1.6

9.6

MO132-2.5

2.5

15

1/6

2.5

15

MO132-4.0

1/8

4

24

1/3

4

24

MO132-6.3

1/4

6.3

37.8

1/2

6.3

37.8

MO132-10

1/2

9.8

58.8

1-1/2

10

60

MO132-12

1/2

9.8

58.8

2

12

72

MO132-16

1

16

96

2

12

72

MO132-20

1-1/2

20

120

3

17

92

MO132-25

2

24

144

3

17

127

MO132-32

2

24

144

5

28

162

Motor rating, three phase

hp

Horse power

FLA Full load amps

LRA Locked rotor amps

Type

220 ... 240 V AC

440 ... 480 V AC

500 ... 600 V AC

hp

FLA

LRA

hp

FLA

LRA

hp

FLA

LRA

MO132-0.16

-

0.16

0.96

-

0.16

0.96

-

0.16

0.96

MO132-0.25

-

0.25

1.5

-

0.25

1.5

-

0.25

1.5

MO132-0.4

-

0.4

2.4

-

0.4

2.4

-

0.4

2.4

MO132-0.63

-

0.63

3.78

-

0.63

3.78

-

0.63

3.78

MO132-1.0

-

1

6

-

1

6

1/2

1

6

MO132-1.6

-

1.6

9.6

3/4

1.6

9.6

3/4

1.6

9.6

MO132-2.5

1/2

2.5

15

1

2.5

15

1-1/2

2.5

15

MO132-4.0

1

4

24

2

4

24

3

3.9

26

MO132-6.3

1-1/2

6.3

37.8

3

4.8

32

5

6.1

37

MO132-10

3

9.6

64

5

7.6

46

7-1/2

9

51

MO132-12

3

9.6

64

7-1/2

11

64

10

11

65

MO132-16

5

15.2

92

10

14

81

10

11

65

MO132-20

5

15.2

92

10

14

81

15

17

93

MO132-25

7-1/2

22

127

15

21

116

20

22

116

MO132-32

10

28

162

20

27

145

25

27

146

2

2C

D

C

13

10

36C

0

2

01

ABB

|

2

/15

UL 508 – Manual motor controller

Type

Circuit breaker or class R fuse per UL/NEC

480 V / 600 V

Maximum short-circuit current rating

480 V

600 V

kA

kA

MO132-0.16

with minimum interrupting rating of

35,000 rms symmetrical amperes

30

18

MO132-0.25

30

18

MO132-0.4

30

18

MO132-0.63

30

18

MO132-1.0

30

18

MO132-1.6

30

18

MO132-2.5

30

18

MO132-4.0

30

18

MO132-6.3

30

18

MO132-10

30

18

MO132-12

30

18

MO132-16

30

18

MO132-20

30

18

MO132-25

30

18

MO132-32

30

18

General technical data

Type

MO132

Pollution degree

3

Phase loss sensitivity

No

Disconnect function acc. to IEC/EN 60947-2

Yes

Ambient air temperature

Operation

Open

-25 ... +60 °C

Enclosed (IB132)

0 ... +40 °C

Storage

-50 ... +80 °C

Ambient air temperature compensation

-

Maximum operating altitude permissible

2000 m

Resistance to shock acc. to IEC 60068-2-27

25g / 11 ms

Resistance to vibrations acc. to IEC 60068-2-6

5g / 3 ... 150 Hz

Mounting position

Position 1-6 (optional for single mounting)

Mounting

DIN-rail (EN 60715)

Group mounting

On request

Minimum distance to other

units same type

Horizontal

0 mm

Vertical

150 mm

Minimum distance to

electrical conductive board

Horizontal, up to 400 V

0 mm

Horizontal, up to 690 V

> 1.5 mm

Vertical

75 mm

Degree of protection

Housing

IP20

Main circuit terminals

IP20

Connecting characteristics

Main circuit

Type

MO132-0.16 … MO132-10

MO132-12 … MO132-16

MO132-20 … MO132-32

Connecting capacity

Rigid

1 or 2 x

1 ... 4 mm²

1 ... 4 mm²

2.5 ... 6 mm²

Flexible with ferrule

1 or 2 x

0.75 ... 2.5 mm²

0.75 ... 2.5 mm²

1 ... 6 mm²

Flexible with insulated ferrule

1 or 2 x

0.75 ... 2.5 mm²

0.75 ... 2.5 mm²

1 ... 6 mm²

Flexible

1 or 2 x

0.75 ... 2.5 mm²

0.75 ... 2.5 mm²

1 ... 6 mm²

Stranded acc. to UL/CSA

1 or 2 x

AWG 16-12

AWG 16-12

AWG 12-8

Flexible acc. to UL/CSA

1 or 2 x

AWG 16-12

AWG 16-12

AWG 12-8

Stripping length

9 mm

10 mm

10 mm

Tightening torques

0.8 ... 1.2 Nm / 10 … 12 Ib.in 1.5 Nm / 14 Ib.in

2.0 Nm / 18 Ib.in

Connection screw

M3.5 (Pozidriv 2)

M4 (Pozidriv 2)

M4 (Pozidriv 2)

MO132 manual motor starters magnetic only

Technical data

2

2C

D

C

13

105

0

C0

2

01

2

/16 |

ABB

MS116, MS132, MO132 manual motor starters

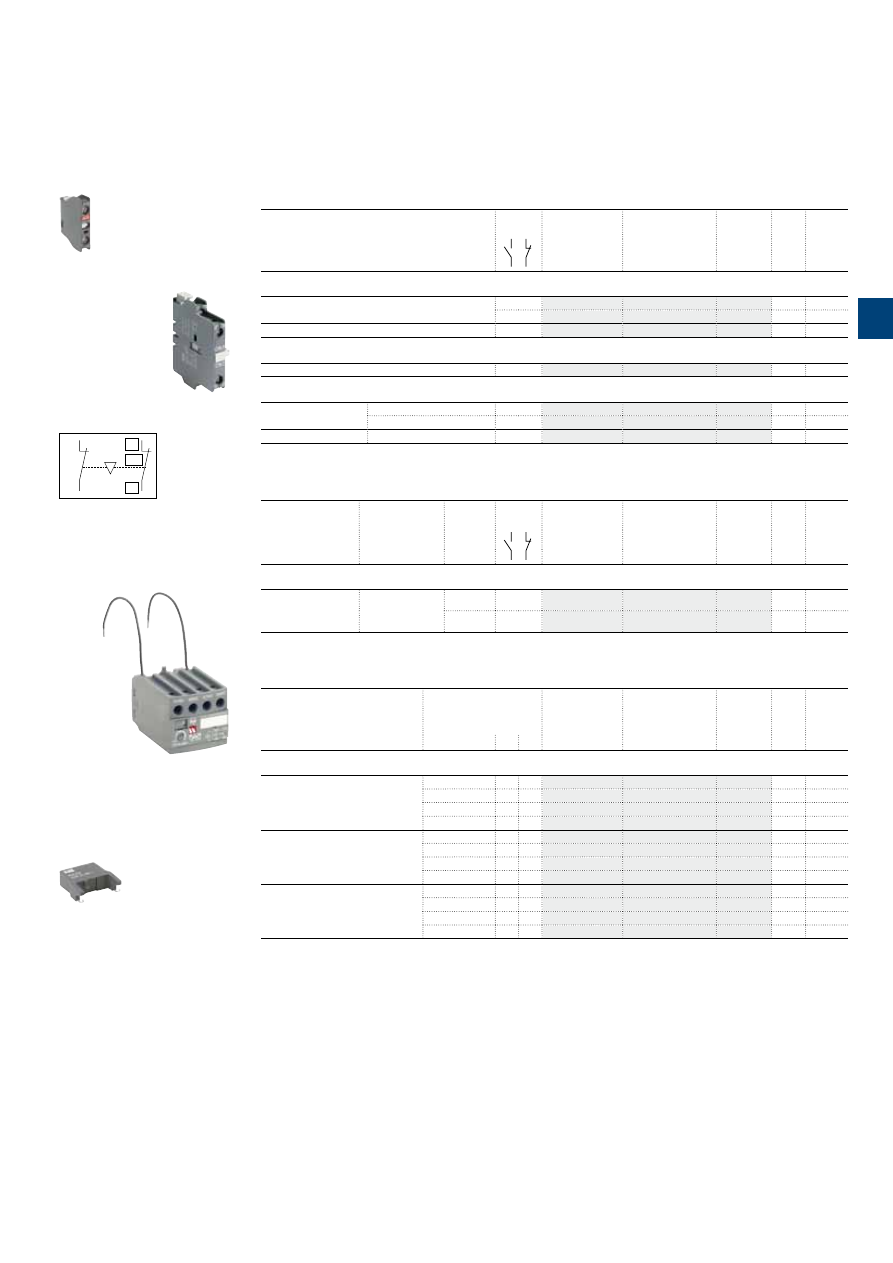

Main accessories

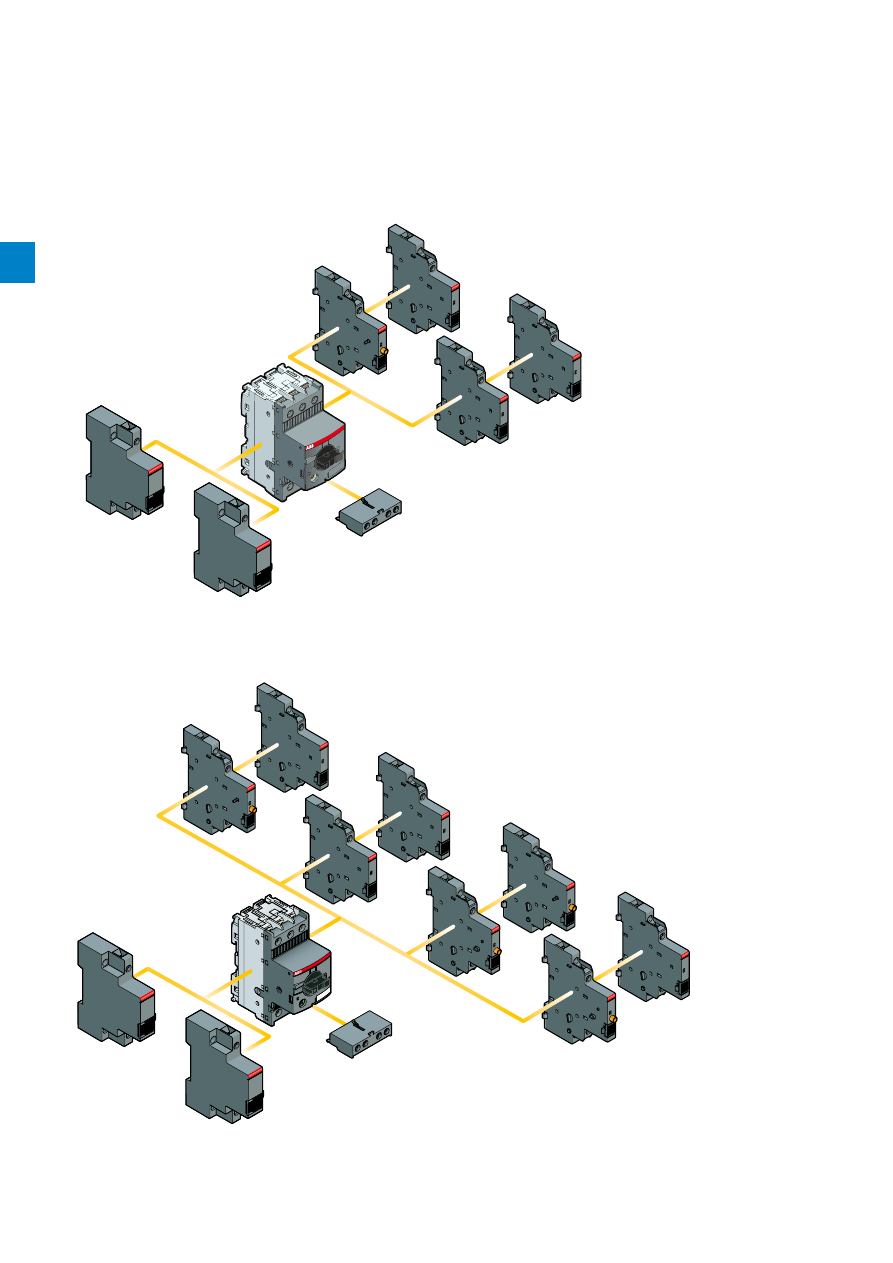

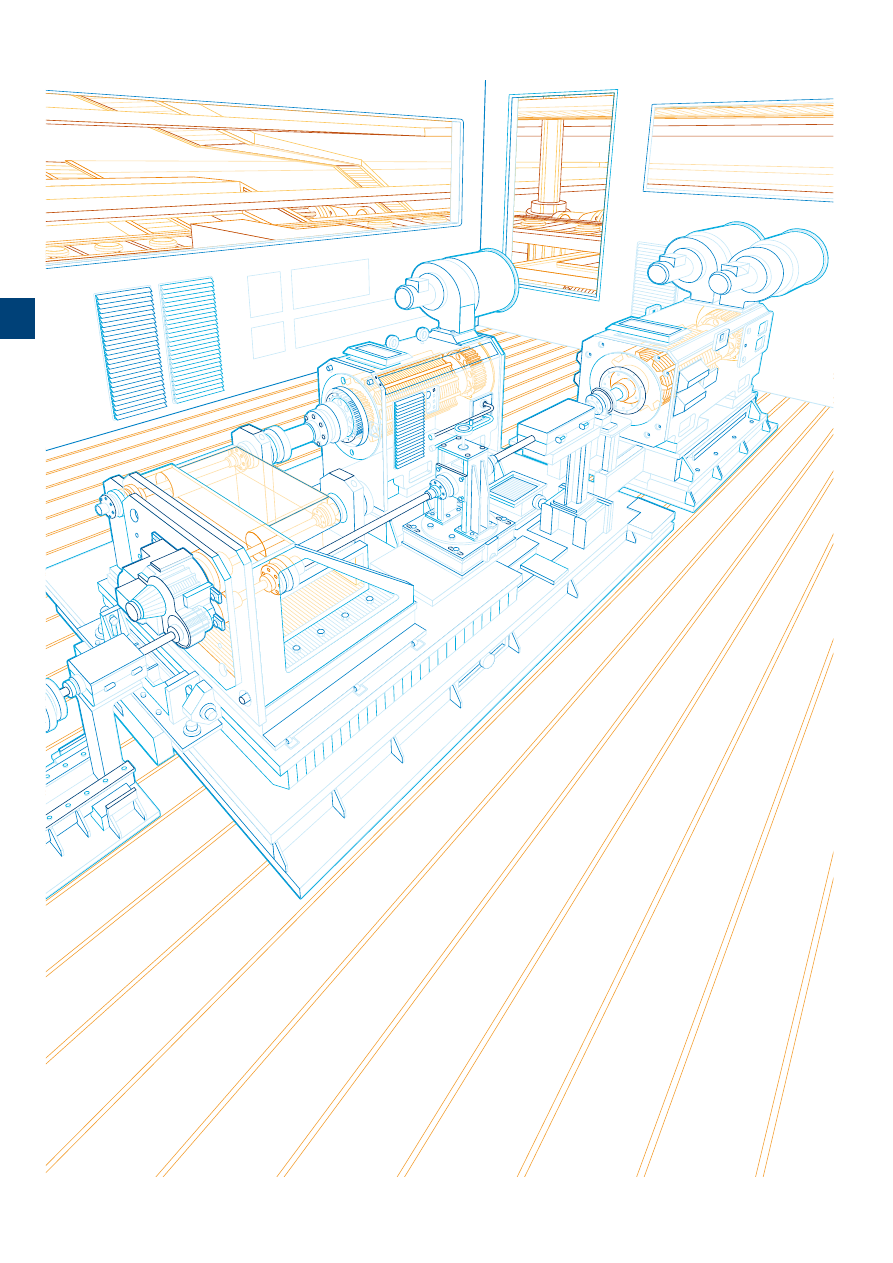

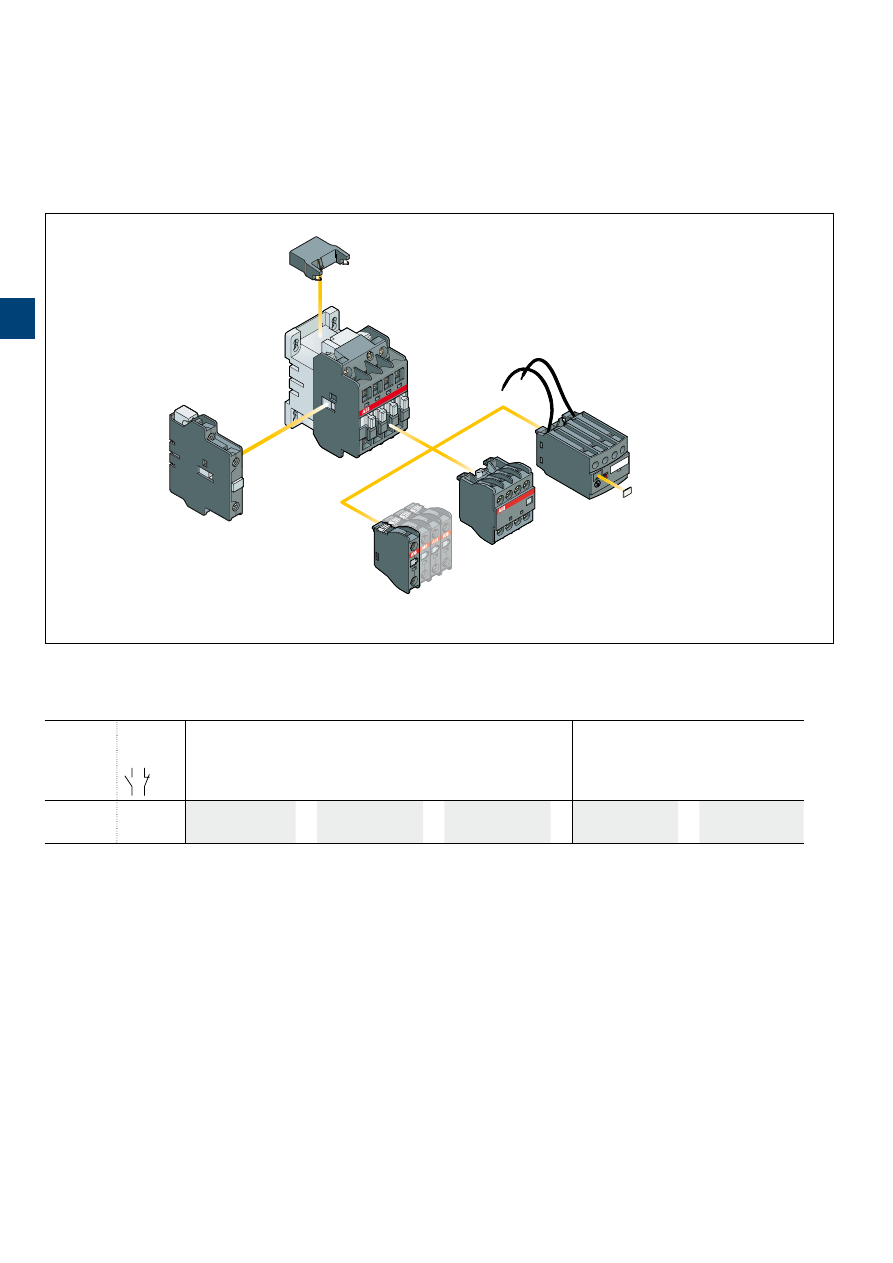

MS116, MO132 manual motor starters with accessories

AA1

UA1

HKF1

SK1

HK1

HK1

HK1

MS116

MO132

2CDC246001F0013

MS132 manual motor starters with accessories

MS132

AA1

UA1

HKF1

SK1

HK1

HK1

HK1

CK1

CK1

HKF1

SK1

1SBC500311F0000

SK1

HK1

HK1

HK1

HKF1

UA1

AA1

MS116

MO132

SK1

SK1

HK1

HK1

HK1

HK1

CK1

CK1

HKF1

UA1

AA1

MS132

2

2C

D

C

13

105

0

C0

2

01

ABB

|

2

/17

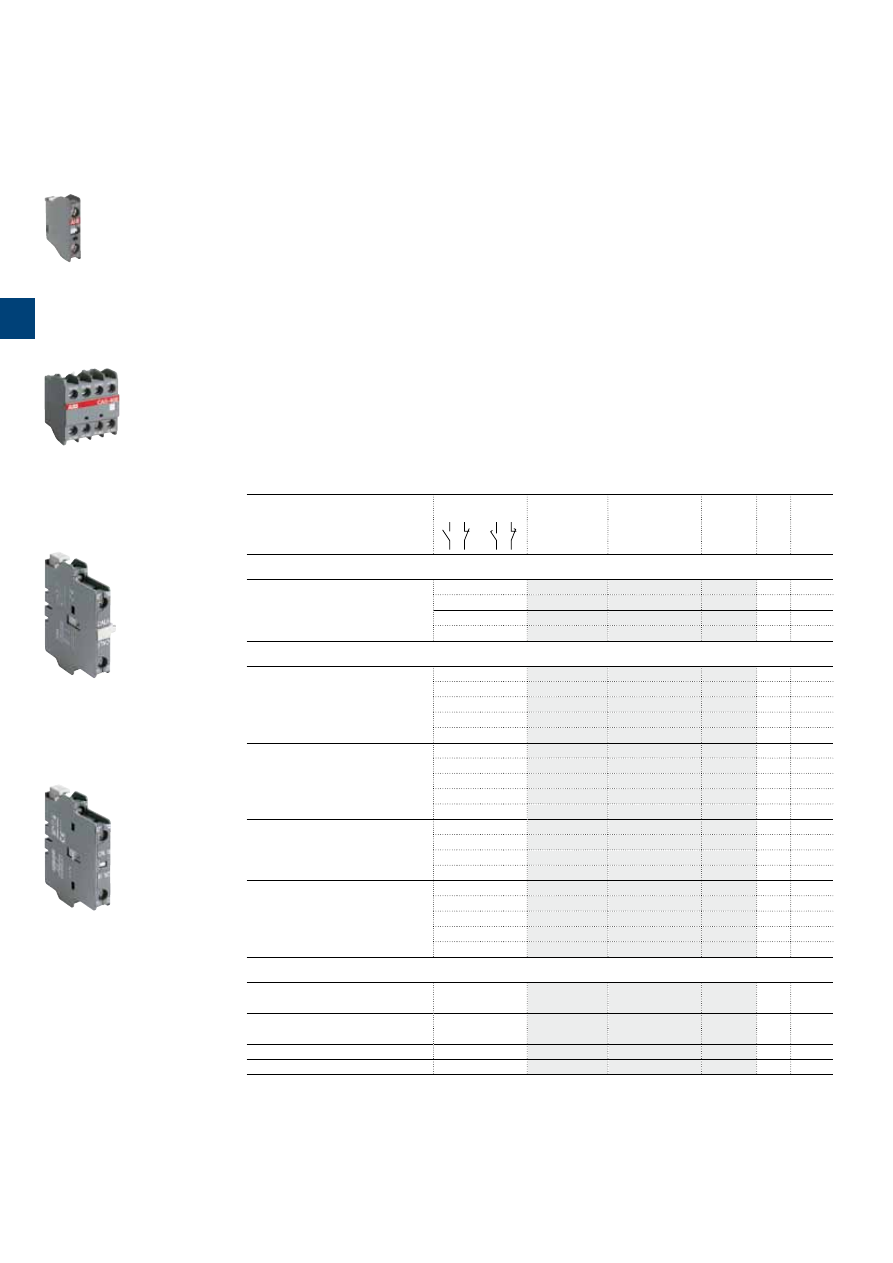

MS116, MS132, MO132 manual motor starters

Main accessories

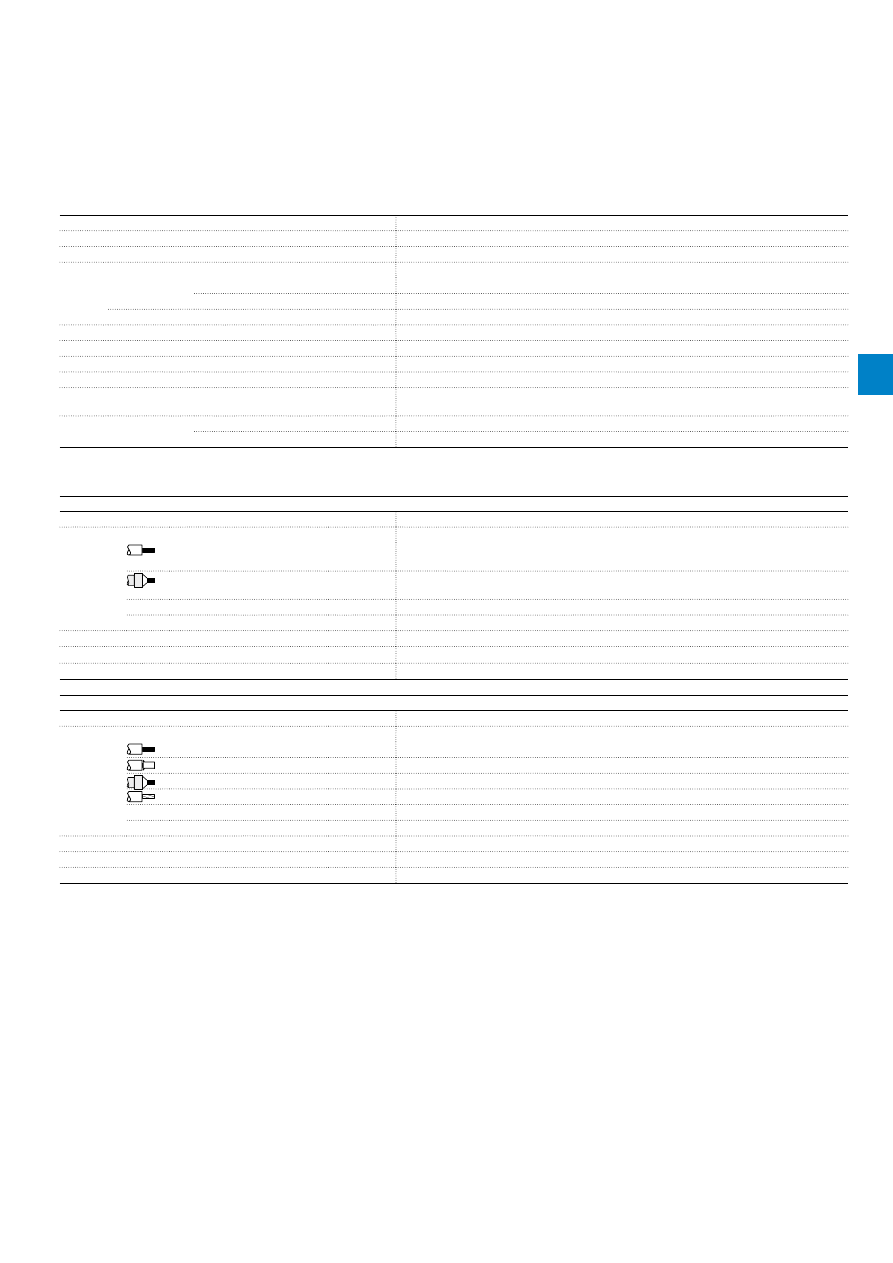

Description

Manual motor starters can be equipped with auxiliary contacts for lateral/front mounting, signalling contact

for lateral mounting, undervoltage release and shunt trips. Two different signalling contacts are available.

The accessories can be fitted wiring free and without tools. A variety of combinations is possible as

required for the application. The auxiliary contacts change position with the main contacts. The signalling

contact SK signals tripping regardless if it was caused by short-circuit or overload. The signalling contact

CK signals tripping in case it was caused by short-circuit. Undervoltage release are used for remote

tripping of the manual motor starter especially for emergency stop circuits. Shunt trips release the MMS

used for remote tripping.

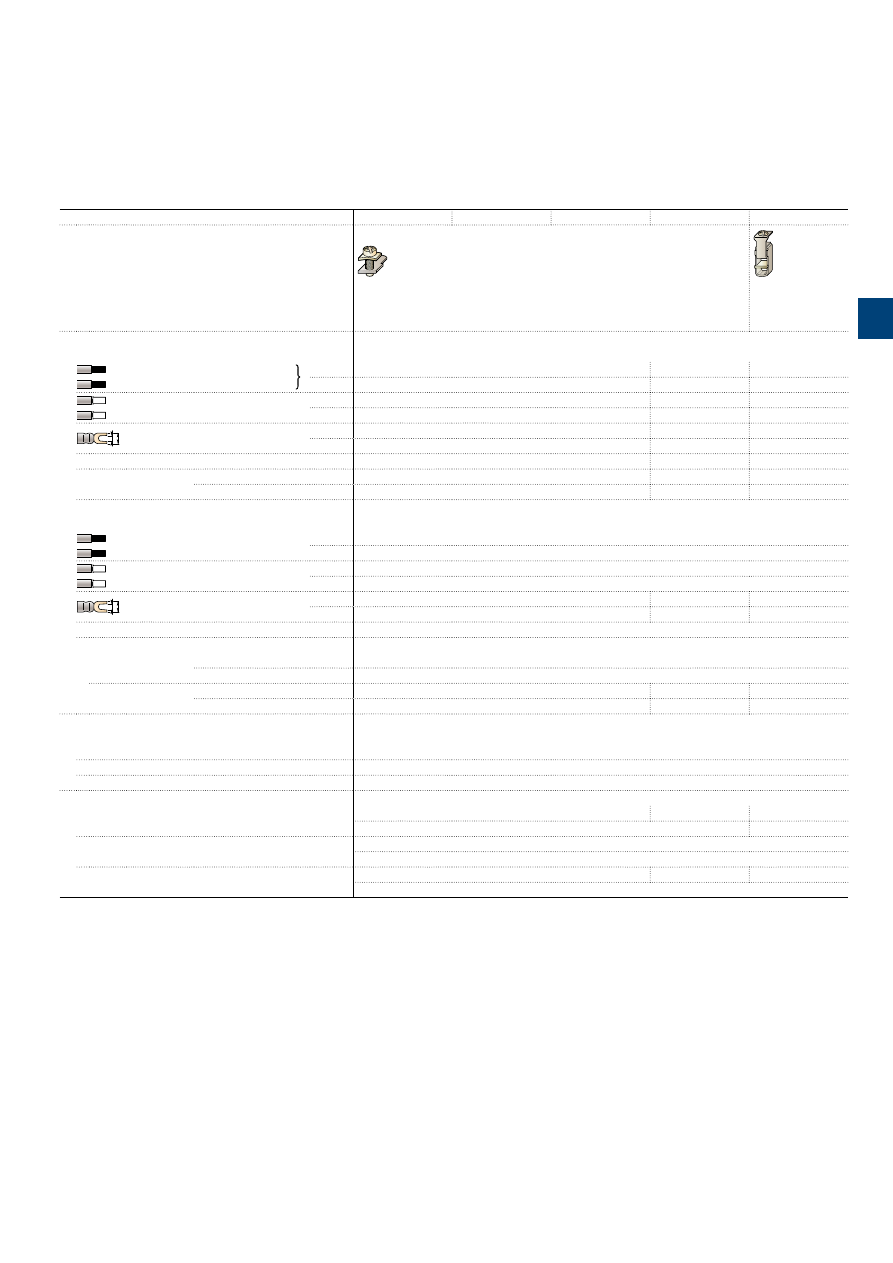

Ordering details

Suitable for

Auxiliary

contacts

N.O.

Auxiliary

contacts

N.C.

Description

Type

Order code

Pkg

qty

Weight

(1 pce)

kg

Auxiliary contacts – mountable on the front

MS116, MS132,

MO132

1

1

HKF1-11

10

0.015

2

0

HKF1-20

10

0.015

Auxiliary contacts – mountable on the right

MS116, MS132,

MO132

1

1

max. 2 pieces

HK1-11

2

0.035

2

0

max. 2 pieces

HK1-20

2

0.035

0

2

max. 2 pieces

HK1-02

2

0.035

2

0

with lead contacts

HK1-20L

2

0.035

Signalling contacts – mountable on the right

MS116, MS132,

MO132

1

1

for tripped alarm,

max. 2 pieces

SK1-11

2

0.035

2

0

for tripped alarm,

max. 2 pieces

SK1-20

2

0.035

0

2

for tripped alarm,

max. 2 pieces

SK1-02

2

0.035

MS132

1

1

for short-circuit alarm,

max. 2 pieces

CK1-11

2

0.035

2

0

for short-circuit alarm,

max. 2 pieces

CK1-20

2

0.035

0

2

for short-circuit alarm,

max. 2 pieces

CK1-02

2

0.035

1SBC101208F0014

HKF1-11

1SBC101209F0014

HK1-11

1SBC101210F0014

SK1-11

1SBC101286F0014

CK1-11

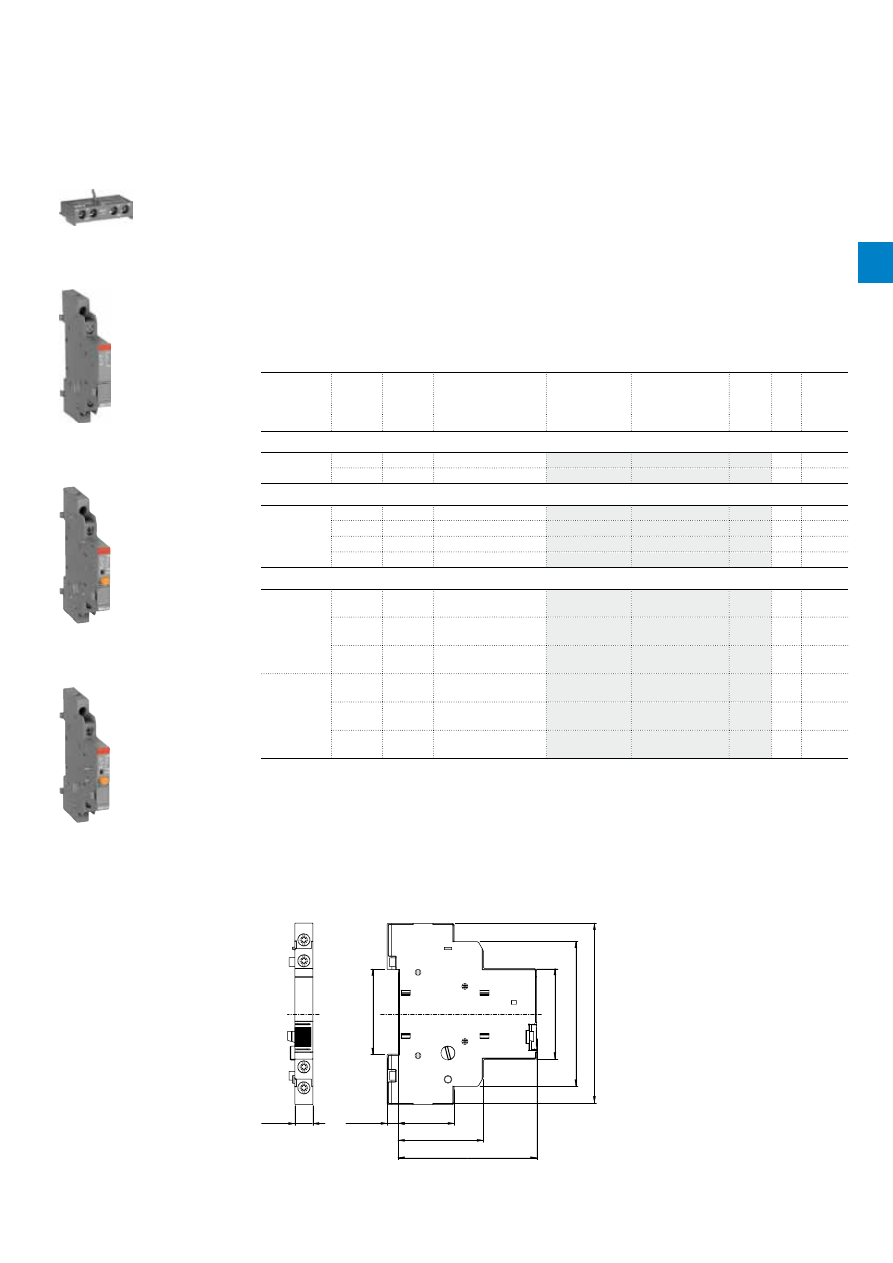

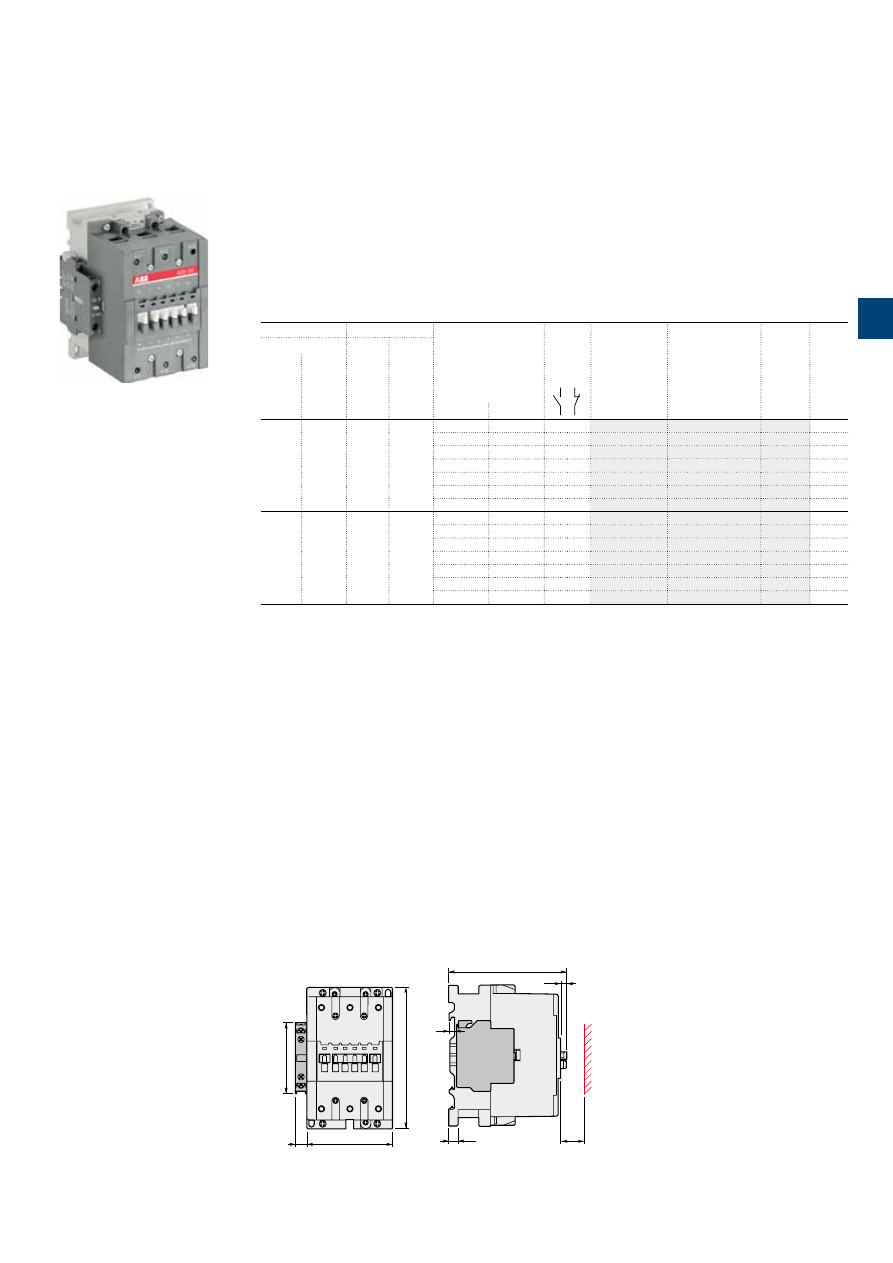

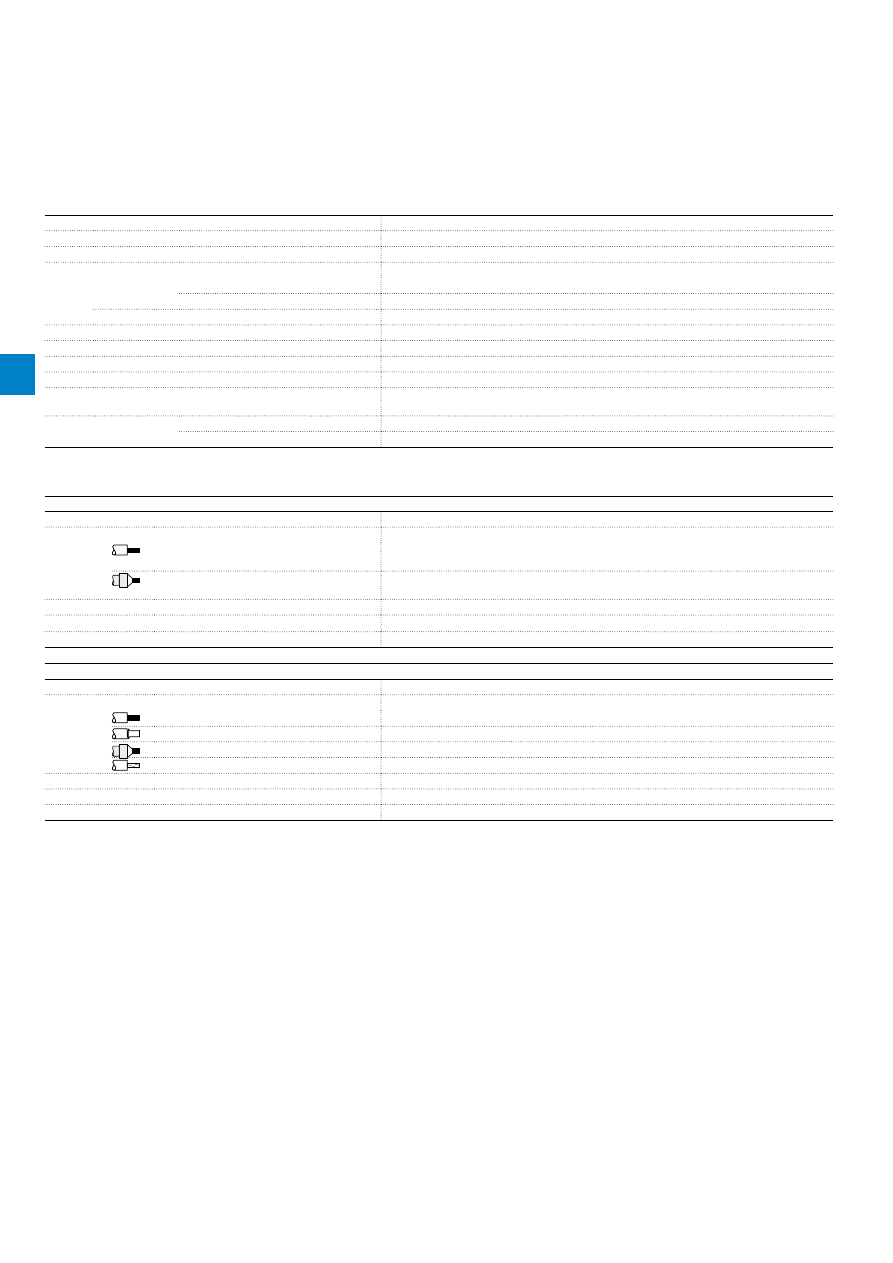

Main dimensions

mm,

inches

5.5

42.3

27.8

68.8

9

90

72

45

42.1

3.54"

0.22"

2.83"

1.77"

1.67"

1.09"

2.71"

1.66"

0.35"

2CDC242001F0012

HK1

2

2C

D

C

13

105

0

C0

2

01

2

/18 |

ABB

MS116, MS132, MO132 manual motor starters

Main accessories

Ordering details

Suitable for

Rated control supply

voltage

Frequency

Type

Order code

Pkg

qty

Weight

(1 pce)

V

Hz

kg

Shunt trips – mountable on the left

MS116, MS132,

MO132

20...24

50/60

AA1-24

1

0.100

110

50/60

AA1-110

1

0.100

200...240

50/60

AA1-230

1

0.100

350...415

50/60

AA1-400

1

0.100

Undervoltage releases – mountable on the left

MS116, MS132,

MO132

24

50

UA1-24

1

0.100

48

50

UA1-48

1

0.100

60

50

UA1-60

1

0.100

110...120

50/60

UA1-110

1

0.100

208

60

UA1-208

1

0.100

230...240

50/60

UA1-230

1

0.100

400

50

UA1-400

1

0.100

415...480

50/60

UA1-415

1

0.100

1SBC101211F0014

AA1-24

1SBC101212F0014

UA1-24

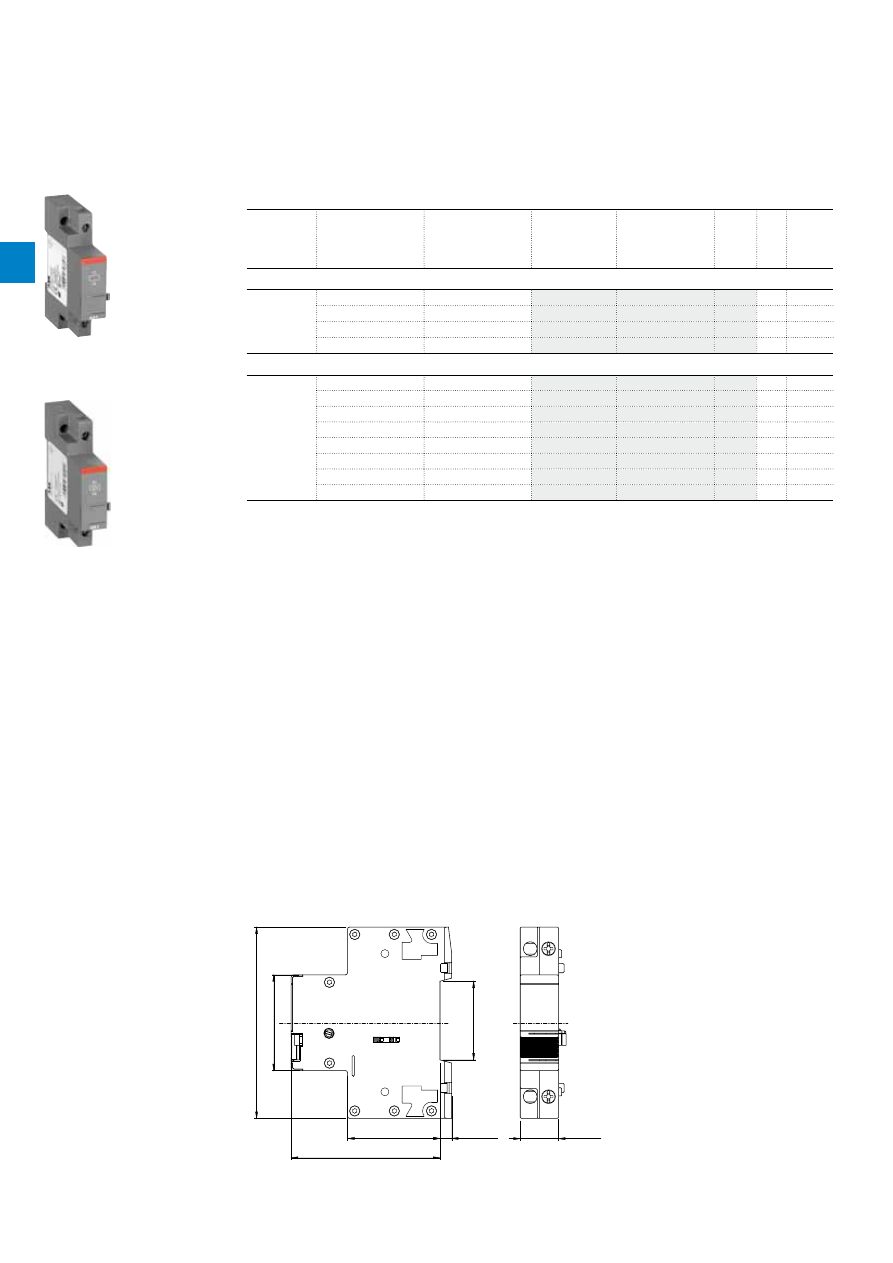

Main dimensions

mm,

inches

90

45

5.5

43.5

70

37

18

3.54"

1.77"

1.71"

2.76"

0.22"

1.46"

0.71"

2CDC242002F0012

AA1, UA1

2

2C

D

C

13

105

0

C0

2

01

ABB

|

2

/19

General technical data

Type

HK1

SK1

HKF1

Standards

IEC/EN 60947-2, IEC/EN 60947-4-1, IEC/EN 60947-1

Rated operational voltage U

e

690 V AC / 600 DC

250 V AC / 250 V DC

Conventional free-air thermal current I

th

6 A

5 A

Rated frequency

50/60 Hz

Rated impulse withstand voltage U

imp

6 kV

Rated insulation voltage U

i

690 V AC

250 V AC

Pollution degree

3

Ambient air temperature

Operation

-25 ... +70 °C

Storage

-50 ... +80 °C

Resistance to shock acc. to IEC 60068-2-27

25g / 11 ms

Resistance to vibrations acc. to IEC 60068-2-6

5g / 3 ... 150 Hz

I

e

/ Rated operational current AC-15

acc. to IEC/EN 60947-5-1 for utilization category

24 V, 120 V

6 A

3 A

240 V

4 A

1.5 A

400 V

3 A

-

440 V, 690 V

1 A

-

I

e

/ Rated operational current DC-13

acc. to IEC/EN 60947-5-1 for utilization category

24 V

2 A

1 A

125 V

0.55 A

0.27 A

250 V

0.27 A

0.11 A

440 V, 600 V

0.15 A

-

Minimum switching capacity

17 V / 5 mA

Short-circuit protective device

N.C., 95-96

10 A Type gG

N.O., 97-98

10 A Type gG

Duty time

100 %

Mounting

Right side of MMS

Front of MMS

Mounting positions

1-6

Mechanical durability

50000 cycles

-

Electrical durability

50000 cycles

-

Connecting charateristics

Auxiliary circuit

Type

HK1

SK1

HKF1

Connecting capacity

Rigid

1 or 2 x

1 ... 1.5 mm²

1 ... 2.5 mm²

Flexible with ferrule

1 or 2 x

0.75 ... 1.5 mm²

Flexible with insulated ferrule

1 or 2 x

0.75 ... 1.5 mm²

Flexible

1 or 2 x

0.75 ... 1.5 mm²

Stranded acc. to UL/CSA

1 or 2 x

AWG 16-14

Flexible acc. to UL/CSA

1 or 2 x

AWG 16-14

Stripping length

8 mm

Tightening torques

0.8 ... 1.2 Nm / 7 Ib.in

Connection screw

M3 (Pozidriv 2)

MS116, MS132, MO132 manual motor starters

Main accessories

2

2C

D

C

13

105

0

C0

2

01

2

/20 |

ABB

MS116, MS132, MO132 manual motor starters

Main accessories

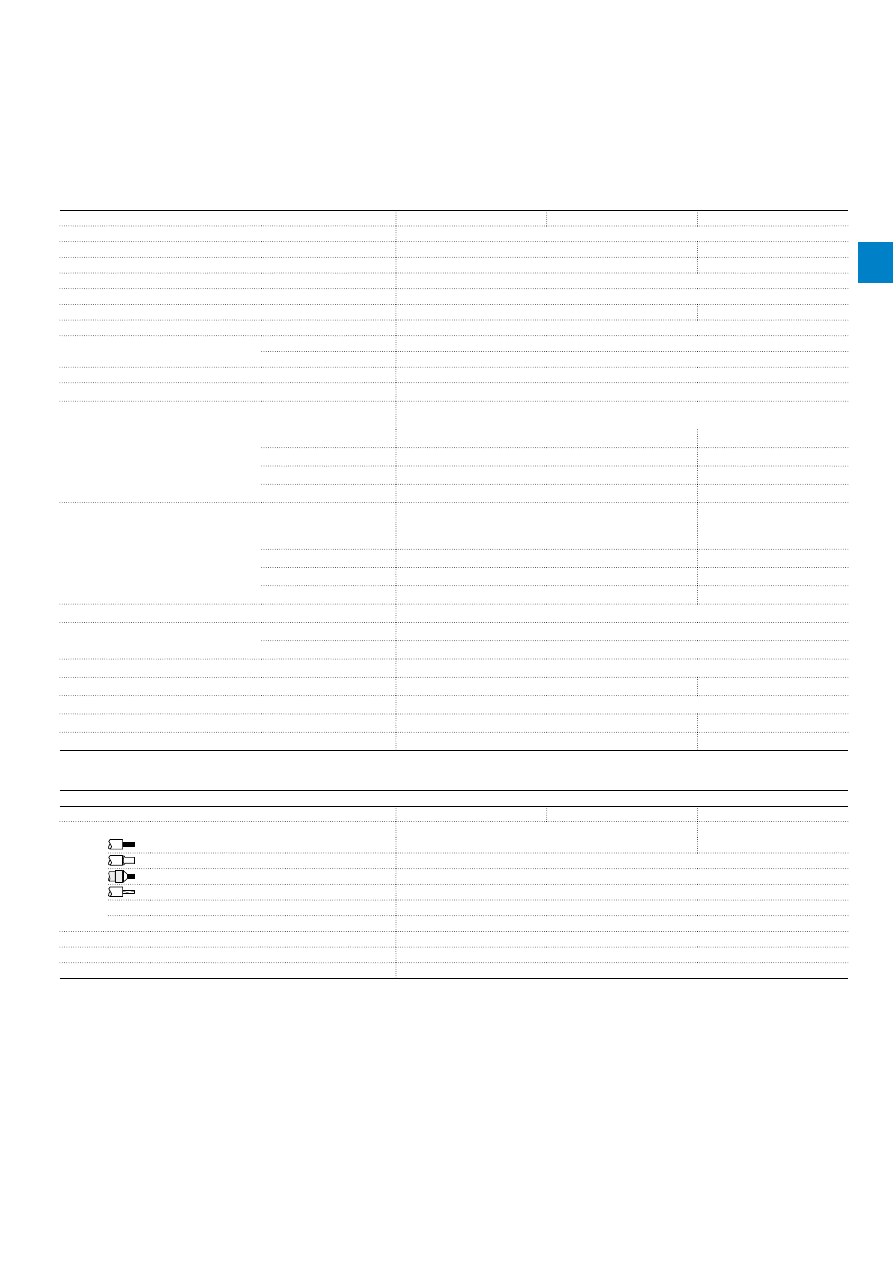

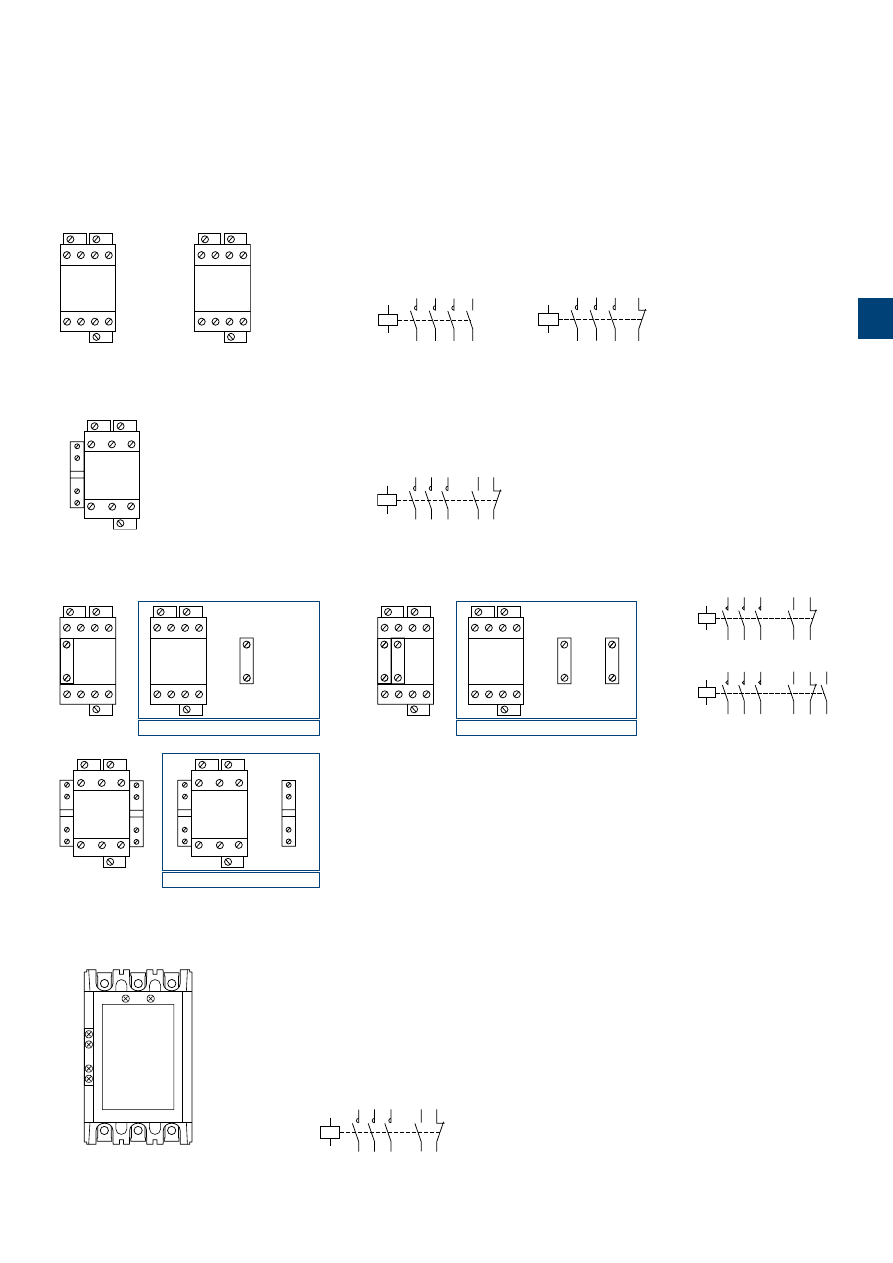

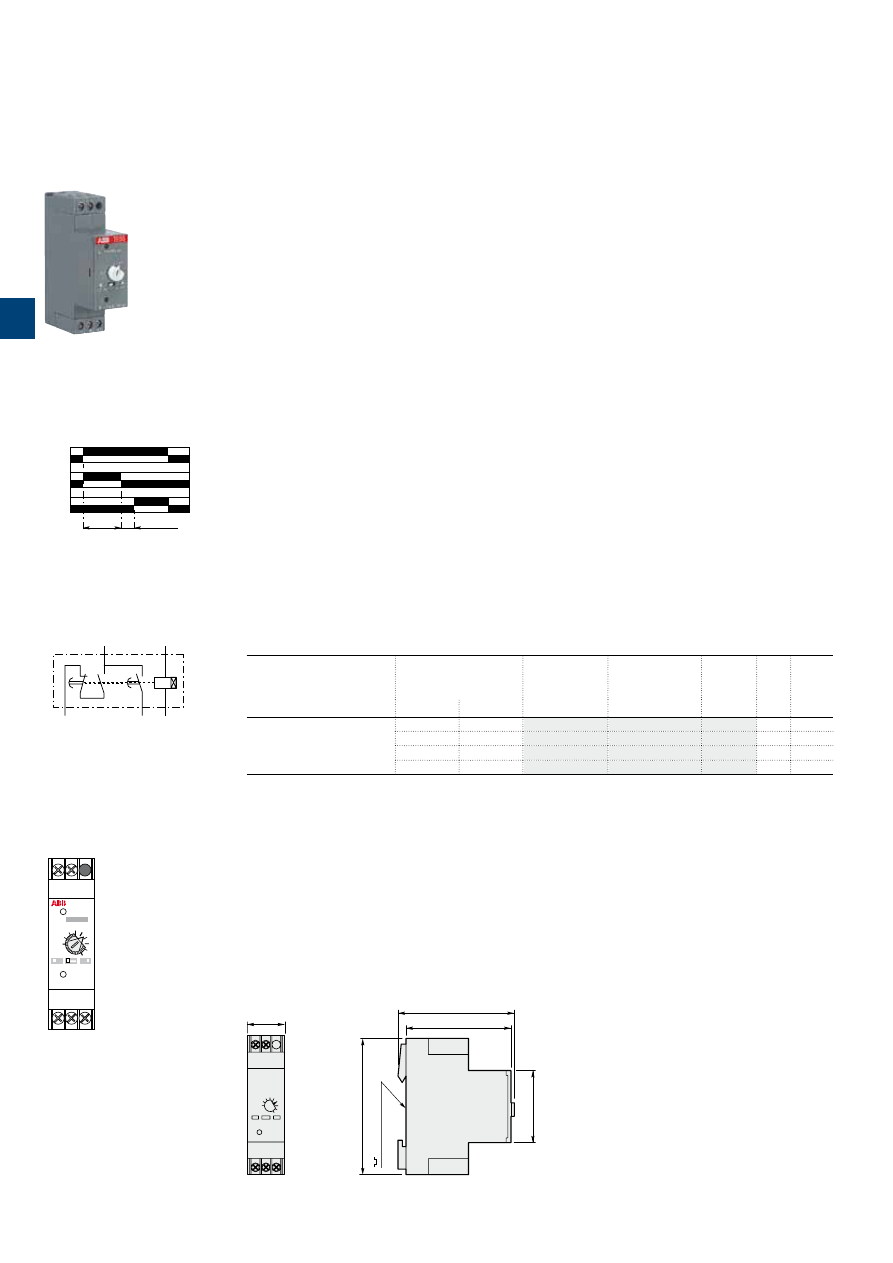

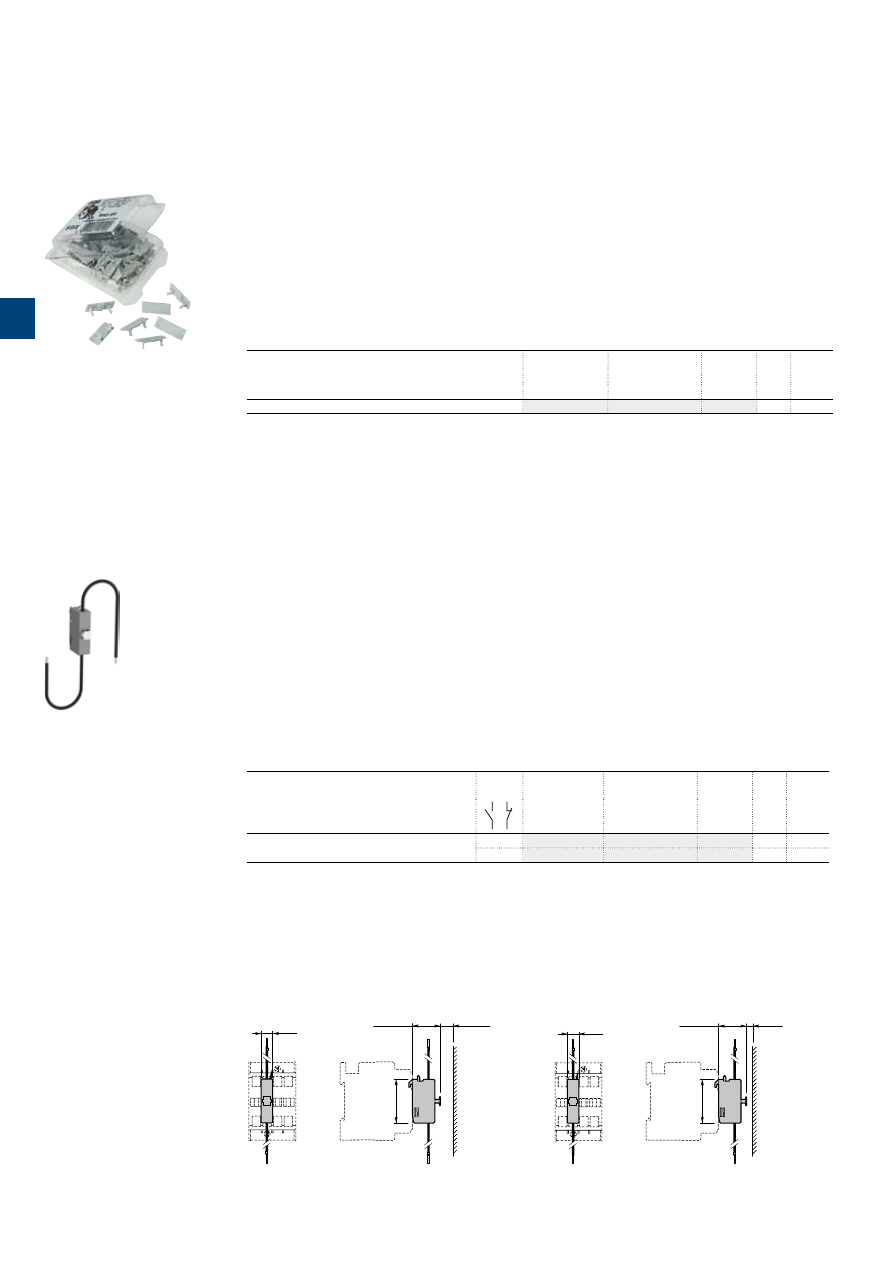

Manual motor starter with three-phase busbar systems

S1-M1-25

PS1-..-65

PS1-..-65

S1-M2-25

BS1-3

SA1

2CDC242020F0013

Three-phase busbar up to 65 A

PS1-..-100

S1-M3-35

2CDC242021F0013

Three-phase busbar up to 100 A

S1-M1-25

S1-M3-35

S1-M2-25

PS1-..-65

PS1-..-100

PS1-..-65

SA1

BS1-3

2

2C

D

C

13

105

0

C0

2

01

ABB

|

2

/21

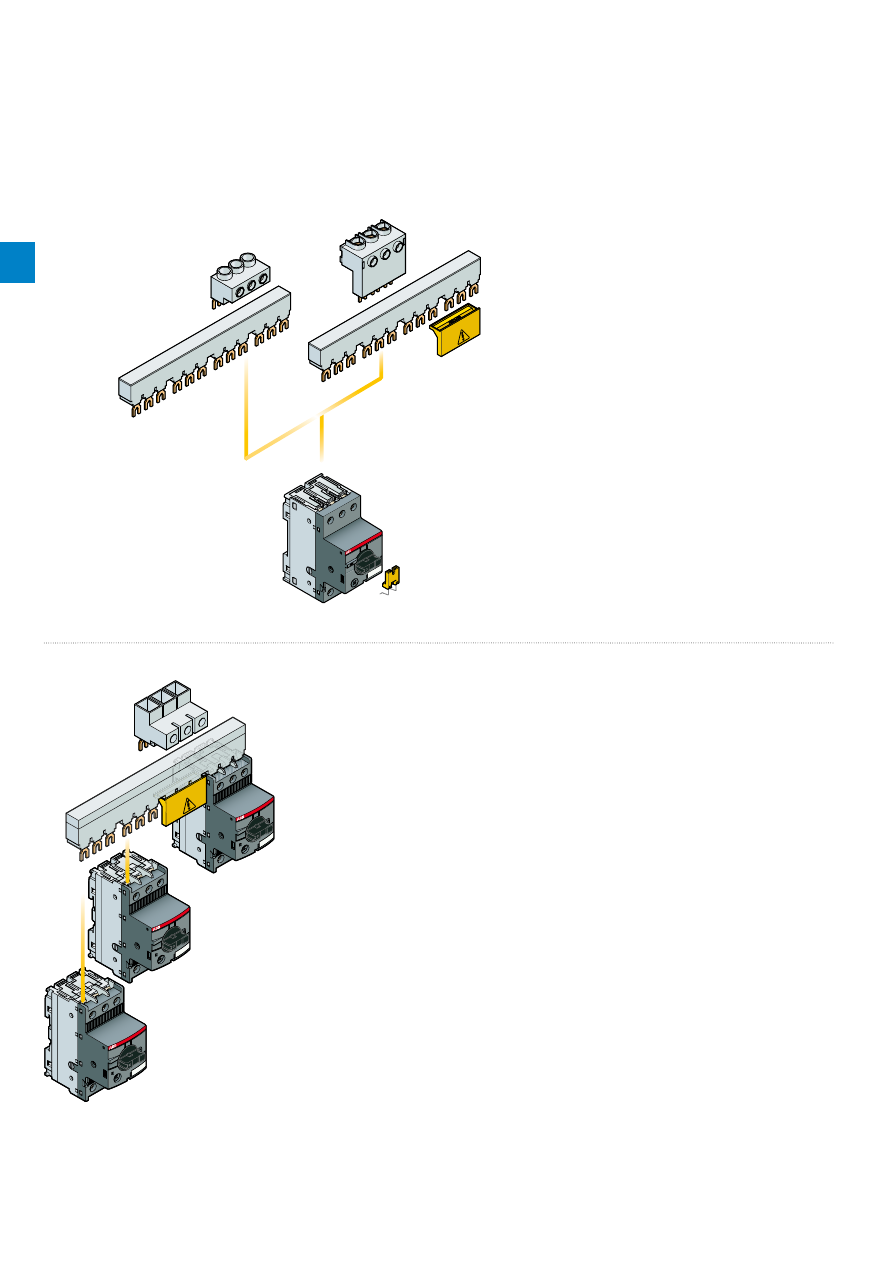

Description

Three-phase busbars ensure a quick and safe connection and are therefore a cost effective solution.

A variety of different three-phase busbars up to 100 A are in the assortment. Between 2 and 5 manual

motor starters with none, one or two lateral auxiliary contacts can be connected. Different three-phase

feeder terminals are available according to the application.

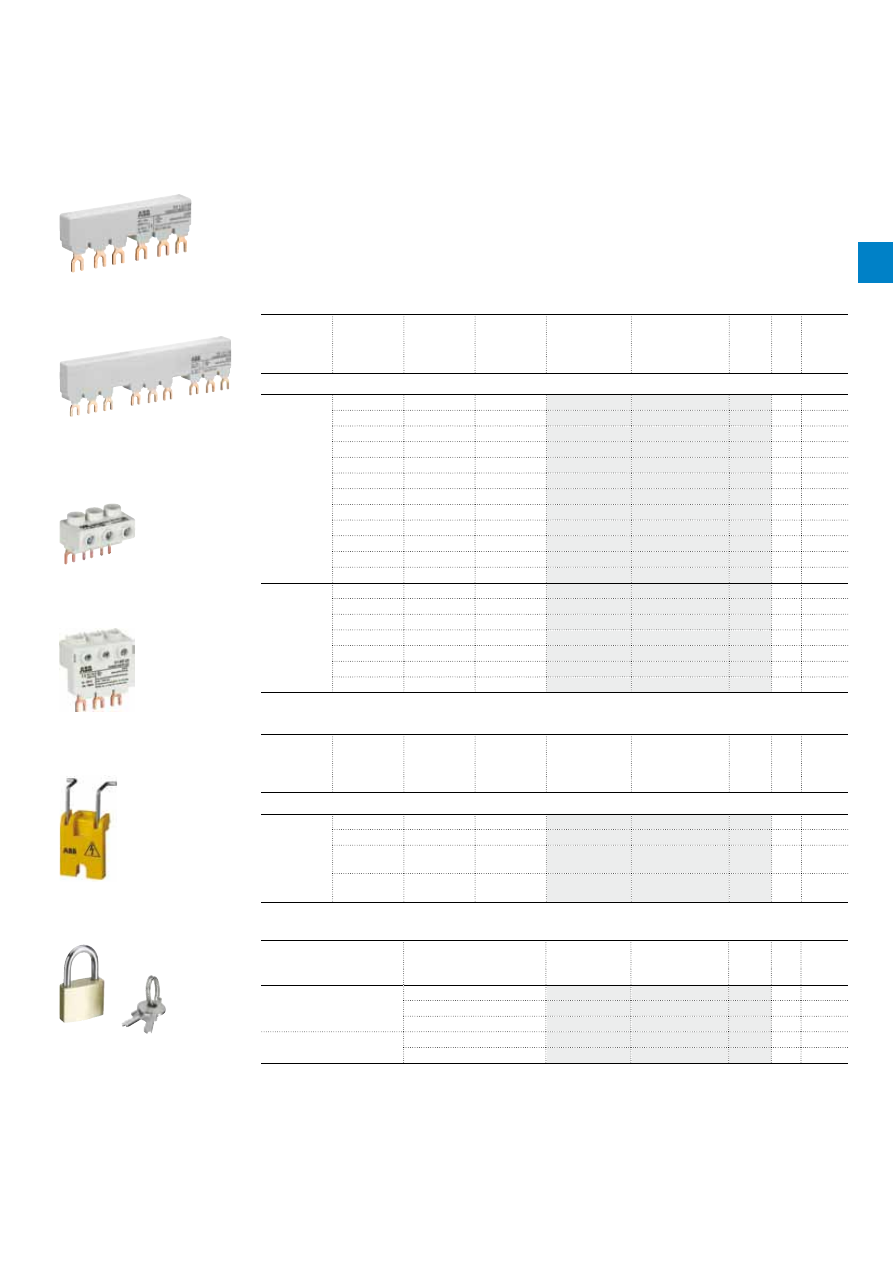

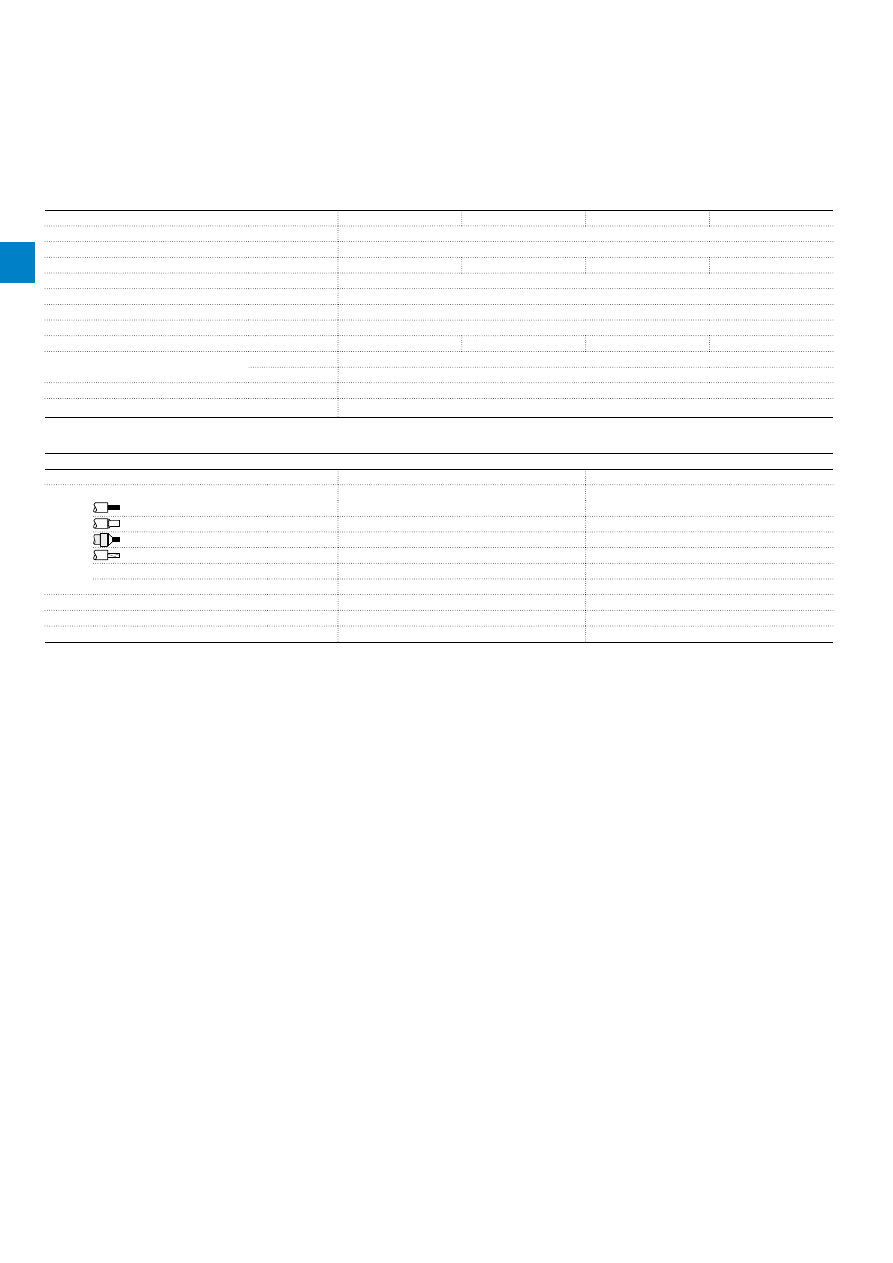

Ordering details

Suitable for

Rated

operational

current

Number of

MMS

Number of

lateral aux.

Type

Order code

Pkg

qty

Weight

(1 pce)

A

kg

Three-phase busbars

MS116, MS132,

MO132

65

2

0

PS1-2-0-65

10

0.034

65

3

0

PS1-3-0-65

10

0.055

65

4

0

PS1-4-0-65

10

0.077

65

5

0

PS1-5-0-65